Anchor cable-reinforced soil combined retaining member and construction method thereof

A technology of reinforced soil and components, which is applied in basic structural engineering, excavation, artificial islands, etc., can solve the problems of easy damage to the reinforcement, and achieve the effect of facilitating the production of prefabrication, saving manpower, and avoiding the destruction of the reinforcement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

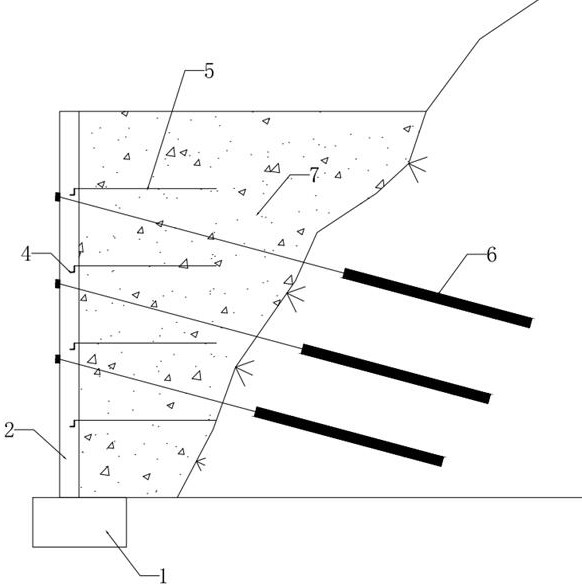

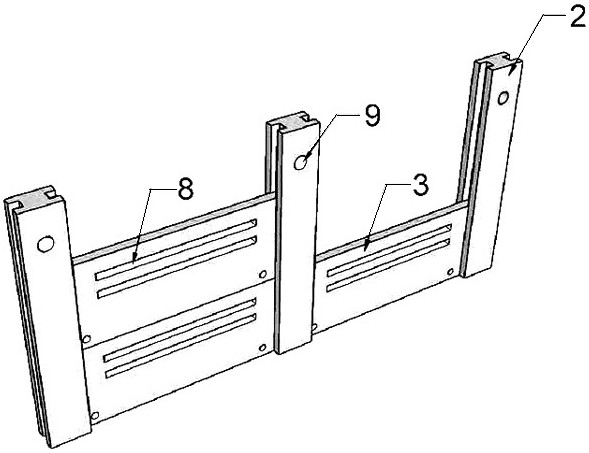

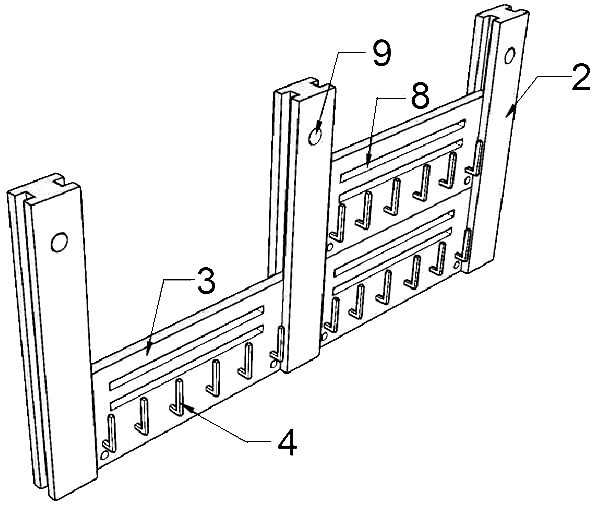

[0039] Refer to attached figure 1 Shown is the anchor cable-reinforced soil combined soil retaining member of this embodiment, including foundation 1, I-shaped column 2, flat wall module 3, steel bar connector 4, geogrid 5, anchor rod 6, filler 7 , drainage channel 8, anchor hole 9. The drainage channel 8 can be provided with a reasonable shape and size as required, and is not limited to a strip channel. refer to Figure 2-Figure 3 , the I-shaped column 2 is clamped and embedded on the foundation 1, and the flat wall module 3 is inserted into the flange of the adjacent I-shaped column 2, referring to Figure 4-Figure 5 , the back of the flat wall module 3 has a steel connector 4, and a drainage channel 8 on the wall; the steel connector 4 is an "L" steel member, and a gap is formed between the steel connector 4 and the flat wall module 3, One end of the geogrid 5 is sleeved on the reinforcement connector 4 and stuck in the gap, so that the reinforcement connector 4 and the ...

Embodiment 2

[0050] In this embodiment, the main structure is the same as that of Embodiment 1, the difference is that the clamping material is a rib-type geogrid, refer to Figure 7 As shown, when the flat wall module 3 is connected with the ribs 11, the ribs 11 can be tied to a horizontal steel bar 10 first, and then the horizontal steel bar 10 can be inserted into a row of "L" shaped steel bars to embed in the gap .

[0051] Concrete construction steps are in the reinforced soil construction process of step 4 in embodiment 1, when the reinforcement material embedded in the back of the wall panel is the rib band 11, the rib band 11 can be bound on a horizontal steel bar 10 earlier, Insert the horizontal steel bar 10 bound with the rib band 11 into the "L" shaped steel bar member. When the soil subsides, the tendon band 11 can move downward along the "L" shaped reinforcement member, which effectively reduces the damage of the reinforcement due to the settlement of the slope.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com