A modified lithium battery negative electrode and its preparation method and application

A lithium battery and modification technology, which is applied in the direction of battery electrodes, lithium batteries, active material electrodes, etc., can solve the problem that the interface performance between the coating and metal lithium cannot be well guaranteed, limiting the stable cycle of metal lithium, and the volume expansion of metal lithium, etc. problem, to achieve the effect of realizing dendrite-free deposition, improving the bonding interface, and enhancing the interface bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

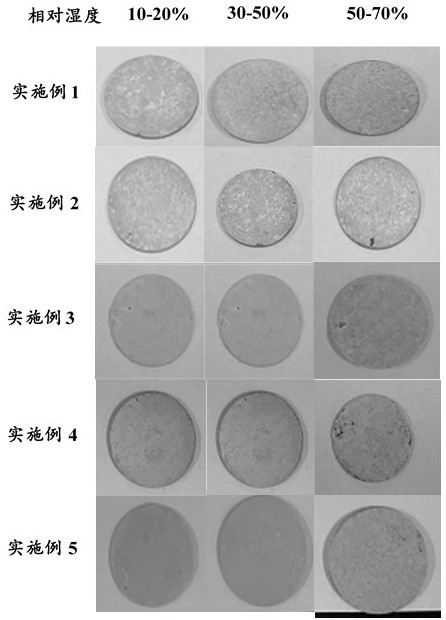

Embodiment 1

[0095] 1. In an argon atmosphere (both water and oxygen content is less than 0.1ppm), take polyanionic polymer sodium polystyrene sulfonate and dissolve it in diethyl carbonate, prepare it into a 3mol / L solution, and then take a 50μm thick The lithium foil was soaked in the above solution to make the metal lithium surface bear a certain amount of negative charge. The soaking time was 30 minutes. After taking it out, it was washed with diethyl carbonate and dried at 40°C for 10 hours to obtain a modified lithium layer.

[0096] 2. In an argon atmosphere (both water and oxygen content is less than 0.1ppm), take 5g of fluorosilicone resin (molecular weight: 1513), then add 10ml of triethyl phosphate to dilute it 10 times, stir magnetically for 60min, add 2g of Tetraethyl orthosilicate (TEOS), mixed with magnetic stirring until uniform, to obtain modified fluorosilicone resin. Dissolve PVDF in NMP and disperse, stir well for 1 hour, then add carbon nanotubes and modified fluorosil...

Embodiment 2

[0100] Step 1 and step 2 are identical with embodiment 1;

[0101] 3. In an argon atmosphere (both water and oxygen content is less than 0.1ppm), the two sides of the secondary modified fluorosilicone resin layer obtained above are coated with polycationic polymer polydiallyl dimethyl ammonium chloride, and one side is The polycation layer has a thickness of about 1 micron, and is dried at 60° C. for 6 hours to obtain a modified fluorosilicone resin layer.

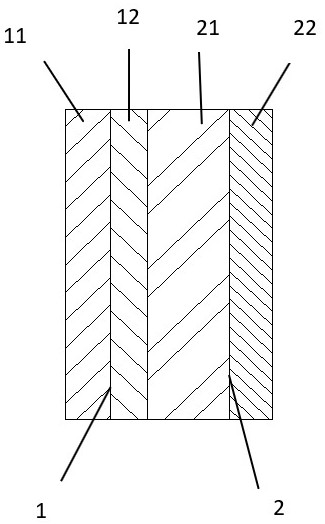

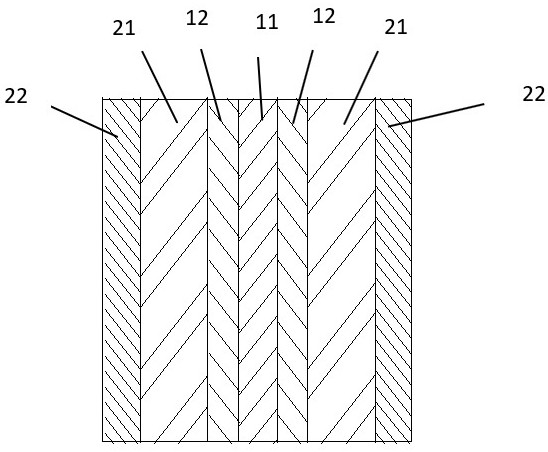

[0102] 4. In an argon atmosphere (both water and oxygen content is less than 0.1ppm), two layers of modified fluorosilicone resin layers are laminated on the surface of the modified lithium layer to form a sandwich structure, that is, modified fluorosilicone resin layer-modified lithium Layer-modified fluorosilicone resin layer; wherein, the polyanion layer and the polycation layer are in contact, the pressure is 10MPa, and the time is 10s to obtain a modified lithium battery negative electrode with a structure such as f...

Embodiment 3

[0104] 1. In an argon atmosphere (both water and oxygen content is less than 0.1ppm), take polyanionic polymer sodium polystyrene sulfonate and dissolve it in dimethyl carbonate, and prepare it into a 2mol / L solution, and then take 100μm The lithium foil is soaked in the above solution, so that the surface of metal lithium has a certain amount of negative charge. The soaking time is 100min. After taking it out, it is washed with dimethyl carbonate and dried at 30°C for 24h to obtain a modified lithium layer.

[0105] 2. In an argon atmosphere (both water and oxygen content is less than 0.1ppm), take 3g of fluorosilicone resin (molecular weight is 5000), then add 8ml of triethyl phosphate to dilute it 8 times, stir it magnetically for 40min, add 2g of fluorosilicone resin TEOS, mixed with magnetic stirring until uniform, to obtain modified fluorosilicone resin. Dissolve PVDF in NMP and disperse, stir well for 1 hour, then add carbon nanotubes and modified fluorosilicone resin r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com