Forestry nursery seeder

A seeder and seeding mechanism technology, which is applied to seeder parts, single seed seeders, agricultural machinery and implements, etc., can solve the problems of low seeder efficiency, improve seeding efficiency, increase crushing force, and achieve self-adaptive effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

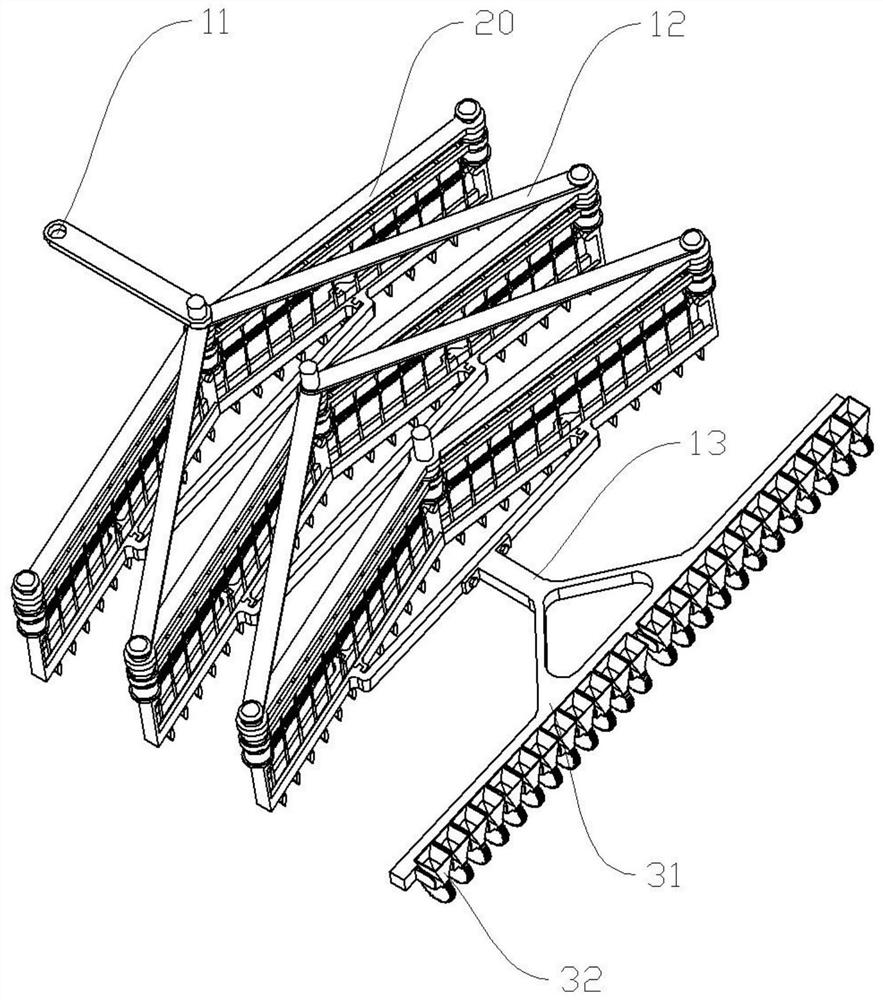

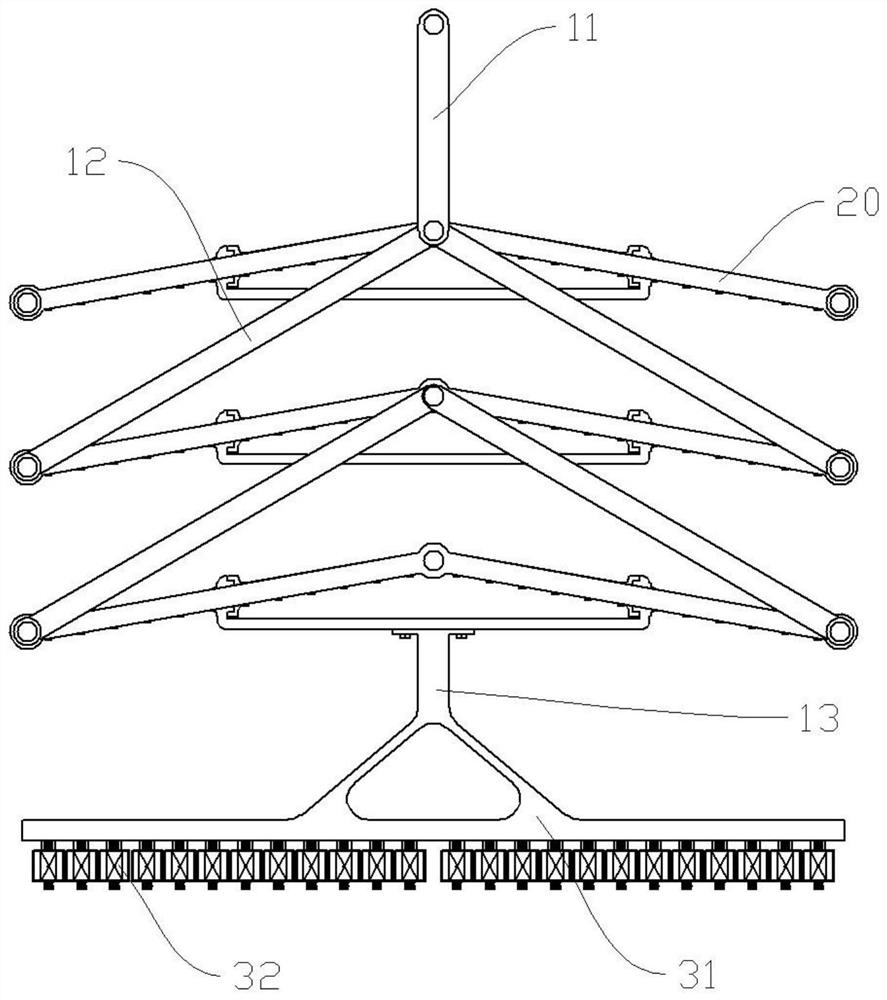

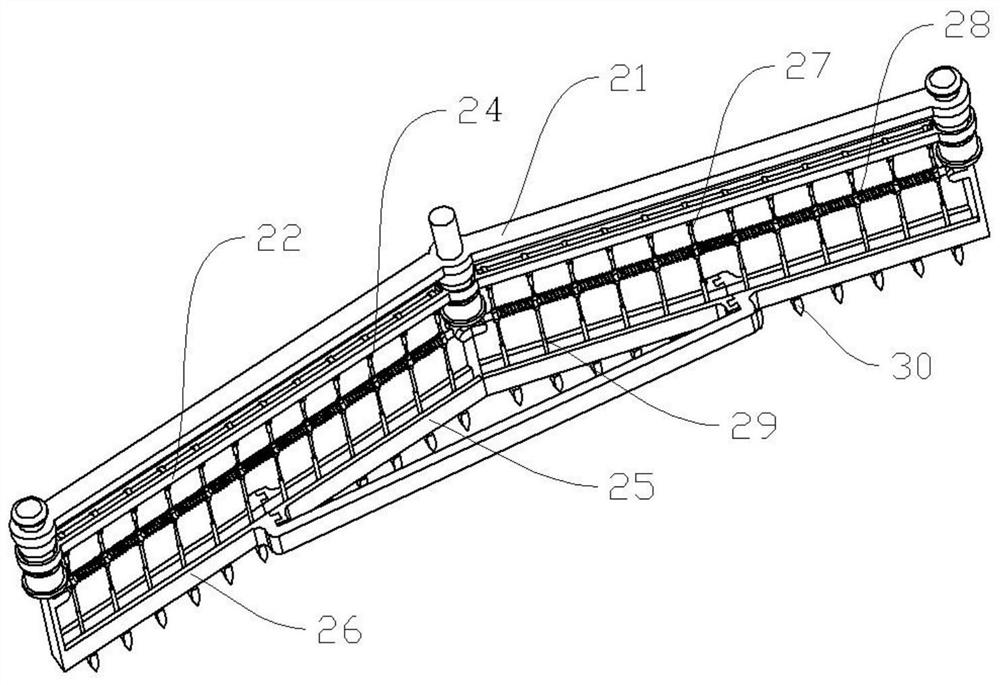

[0030] An embodiment of a forestry nursery seeder of the present invention, such as Figures 1 to 12 As shown, including seed mechanisms and pull cars, further comprising a landing mechanism 20; the landing mechanism 20 includes a mounting rack and a plurality of turbine assemblies. The mounting frame is connected to the front side of the mounting frame, and the sowing mechanism is connected to the rear of the mounting frame to carry out the landing mechanism 20 to carry out the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com