Limestone soil removal system and process

A technology for limestone and slag, applied in the field of limestone soil removal system and process, can solve the problems of high production cost of cement clinker, unable to meet the requirements of ingredients, unable to effectively control the quality of cement products, etc. Cost reduction and better adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

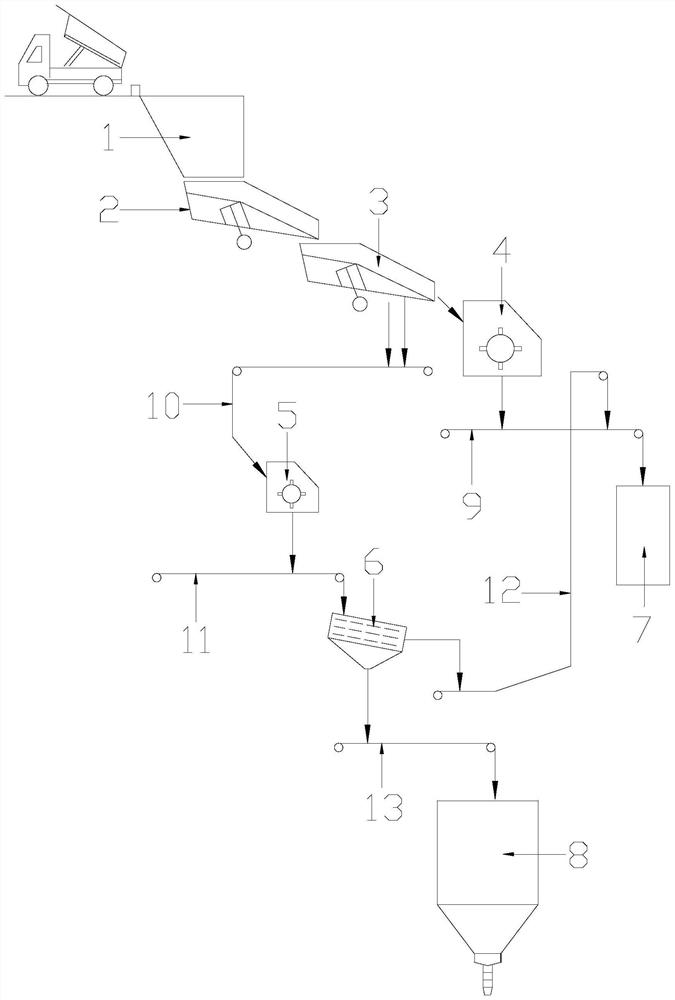

[0021] Embodiment 1: as figure 1 As shown, the limestone soil removal system includes a raw material silo 1, a vibrating feeder 2, a bar screen 3, a finished product crusher 4, a soil removal crusher 5, a vibrating sorting screen 6, a finished product storehouse 7, and a slag storehouse 8. There is a vibrating feeder 2 on the outlet of the raw material bin 1. The vibrating feeder 2 adopts frequency conversion speed regulation, and the feeding is stable and controllable. The feeding amount is 600-1400 tons / hour; Bar screen 3 is installed under the discharge port of 2. Bar screen 3 adopts three-stage screening, the effective length is 6 meters, and the bar gap is adjustable from 80 to 120mm. It can be adjusted according to the particle size of raw materials, and the effective screening capacity is 1500 tons / hour. , the sieve net rate is above 99%; the outlet of the oversize material on the bar sieve 3 is connected with the feed port of the finished product crusher 4, the materia...

Embodiment 2

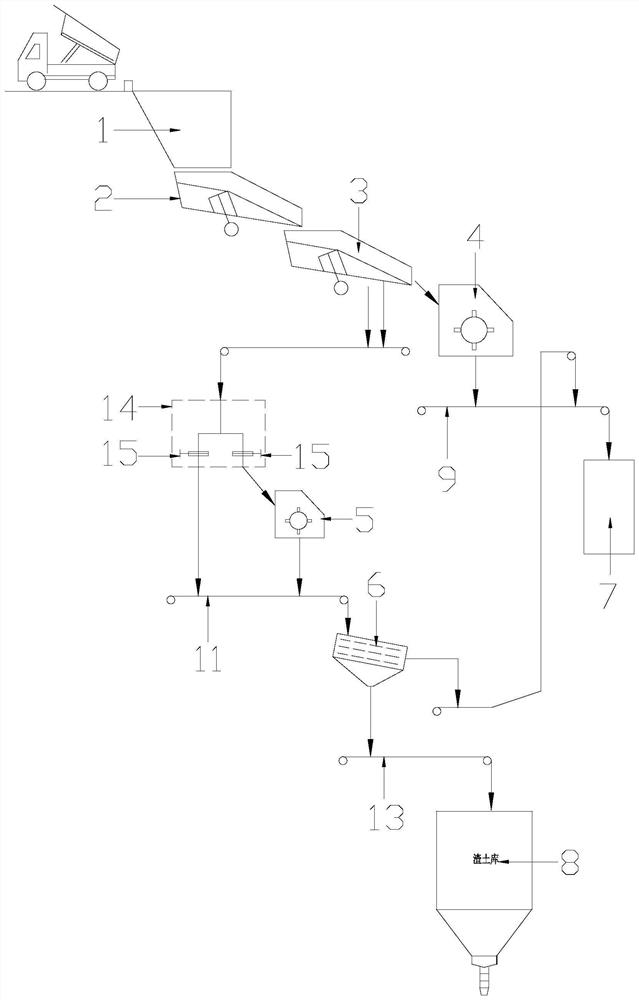

[0022] Embodiment 2: as figure 2 As shown, the limestone soil removal system includes a raw material silo 1, a vibrating feeder 2, a bar screen 3, a finished product crusher 4, a soil removal crusher 5, a vibrating sorting screen 6, a finished product storehouse 7, and a slag storehouse 8; its overall structure is the same as embodiment 1, and its difference is that it also includes a distribution tee 14, placed above the feed inlet of the distribution tee 14 at the discharge port of the preliminary screening conveyor belt 10, and divides A discharge port of the material tee 14 is communicated with the feed port of the soil removal crusher 5; another discharge port of the material distribution tee 14 is placed above the mixing conveyor belt 11; There are gate valves 15 on the discharge ports, which can adjust the process according to the size of the material under the bar screen 3 in actual production, stop using the soil removal crusher 5, and directly use the vibrating sort...

Embodiment 3

[0023] Embodiment 3: limestone desoiling process, it comprises the steps,

[0024] Step 1, once sieved, the mixed material is sieved once using rod sieve 3,

[0025] Step 2, crushing, put the material greater than 120mm selected by the rod sieve in step 1 into the finished product crusher 4 and crush it into the finished product warehouse; put the material less than or equal to 120mm selected in the step 1 into Soil removal crusher 5 is crushed;

[0026] Step 3, secondary screening, using the vibrating sorting screen 6 to carry out secondary screening on the mixed material crushed by the soil removing crusher 5, and after the secondary screening by the vibrating sorting screen 6, the obtained material larger than 5mm will enter the finished product Repository 7, after secondary screening by vibrating sorting sieve 6, the obtained materials less than or equal to 5 mm are put into muck reservoir 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com