Aluminum plate production surface treatment device with adjustable structure

A surface treatment device and an adjustable technology, which can be applied in the direction of grinding/polishing safety devices, manufacturing tools, grinding machine parts, etc., can solve the problems of inconvenient collection of polishing waste, low applicability, and high labor intensity, etc., to achieve Protect the health and atmospheric environment, solve the effect of low applicability and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

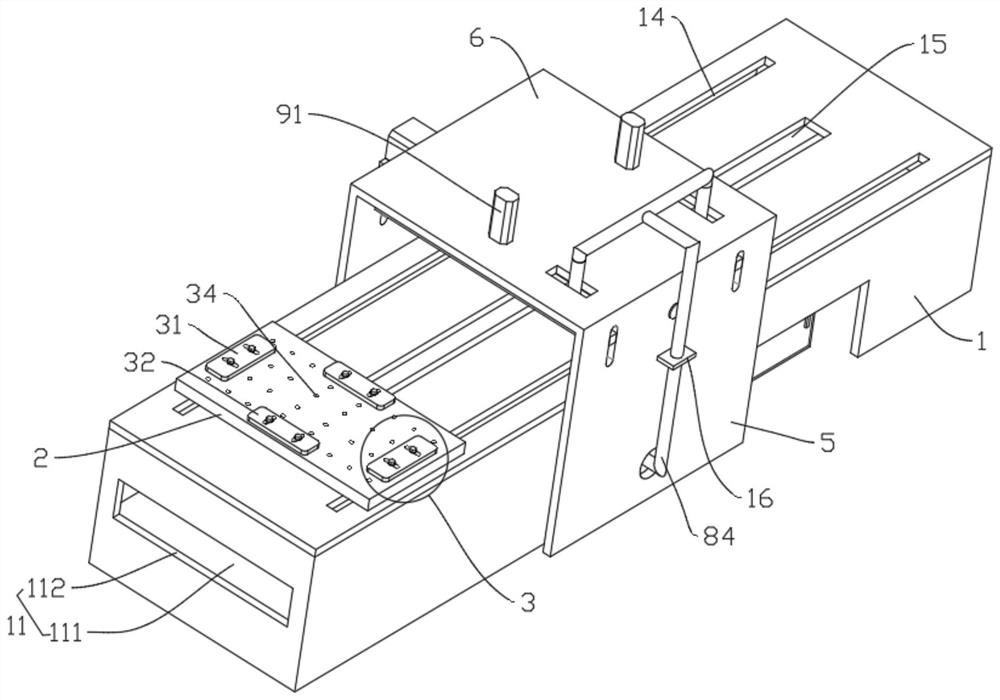

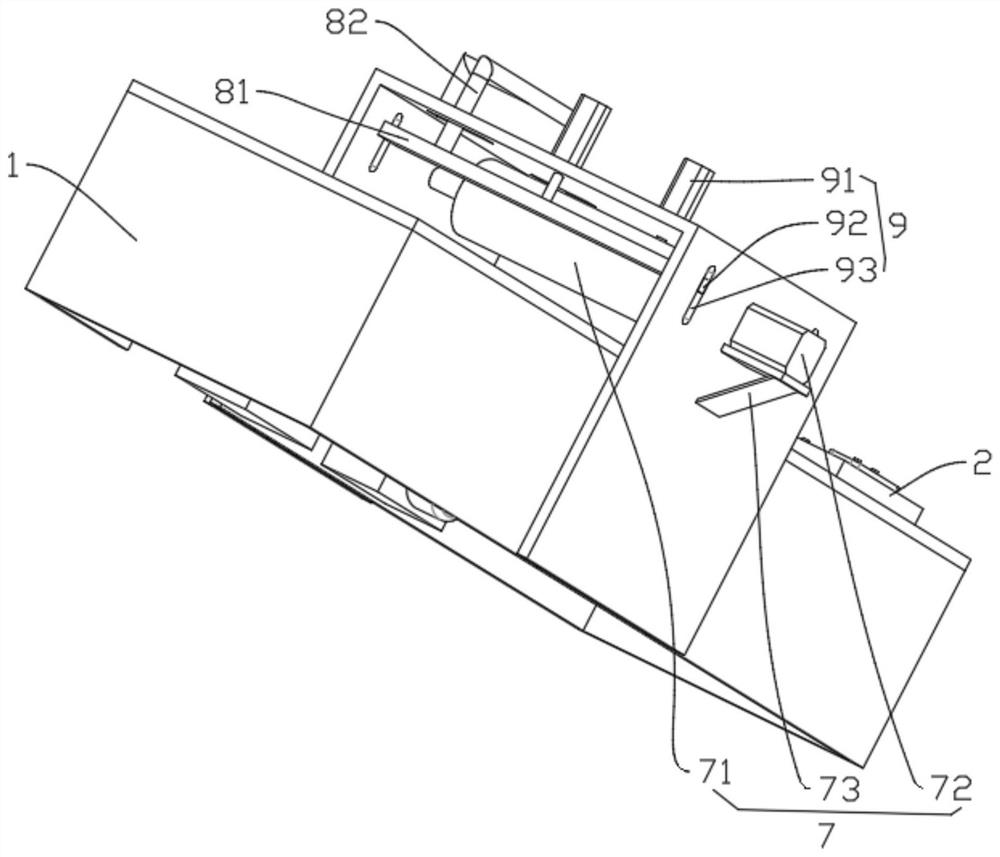

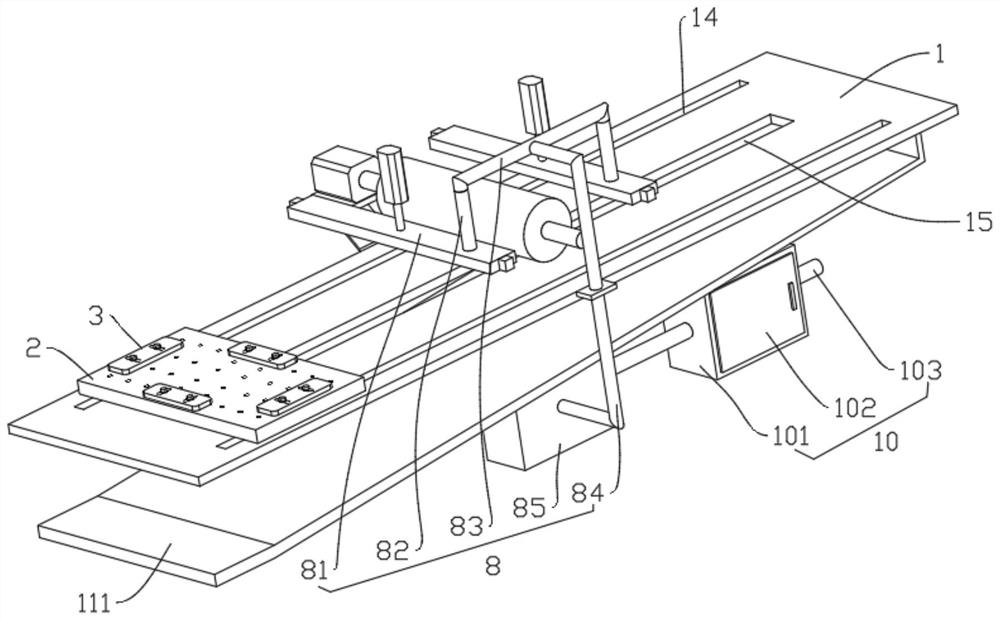

[0031] A surface treatment device for aluminum plate production with an adjustable structure, including an operation table 1, the top of the operation table 1 is slidably connected with a placement plate 2 for placing aluminum plates, and the placement plate 2 is provided with a positioning assembly 3 for positioning aluminum plates. The inner cavity of the table 1 is provided with a driving assembly 4 for driving the movement of the placing board 2, the two sides of the operating table 1 are respectively fixedly connected with vertical boards 5, and the tops of the two vertical boards 5 are jointly fixedly connected with a mounting board 6, A grinding assembly 7 for grinding and cleaning the aluminum plate is arranged between the two vertical plates 5;

[0032] The inner chamber of the console 1 is provided with an adsorption assembly 8 for absorbing grinding waste, the installation plate 6 is provided with an adjustment assembly 9 for adjusting the height of the adsorption as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com