Automatic vacuum casting machine

A vacuum pouring and automatic technology, applied in the field of pouring machines, can solve the problems of taking up a lot of time and long production cycle, and achieve the effect of increasing the scope of application, saving pouring time and shortening the operation cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

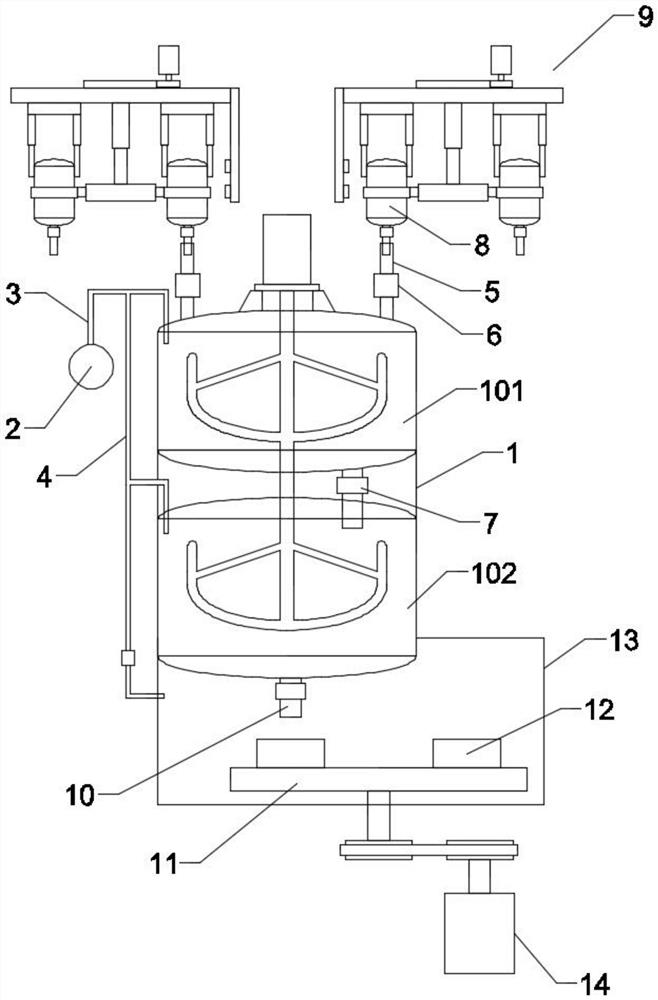

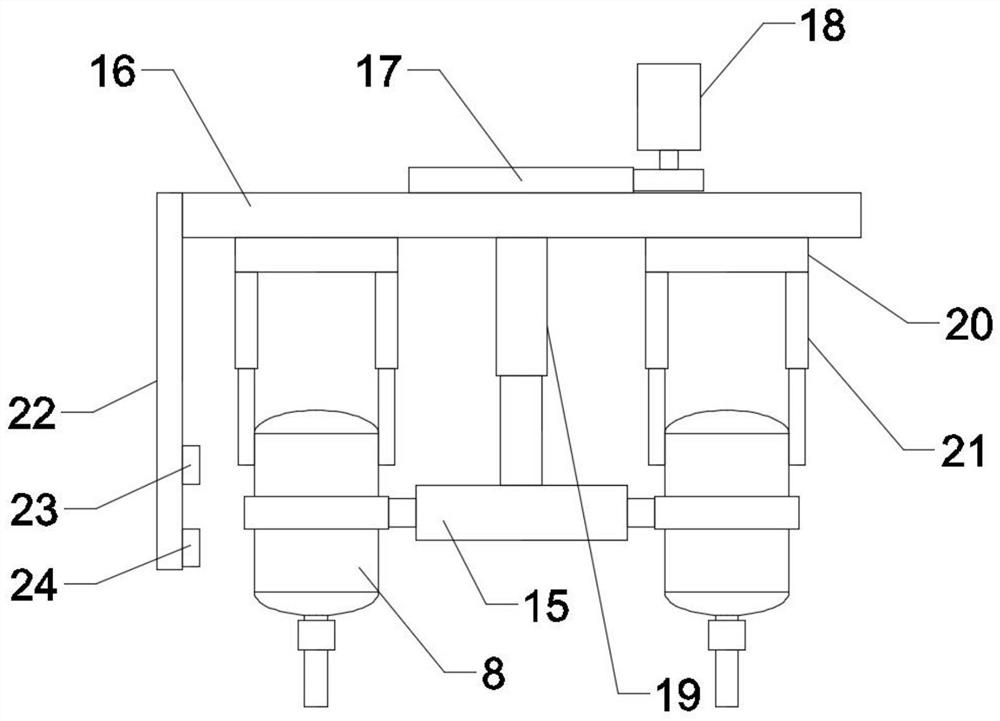

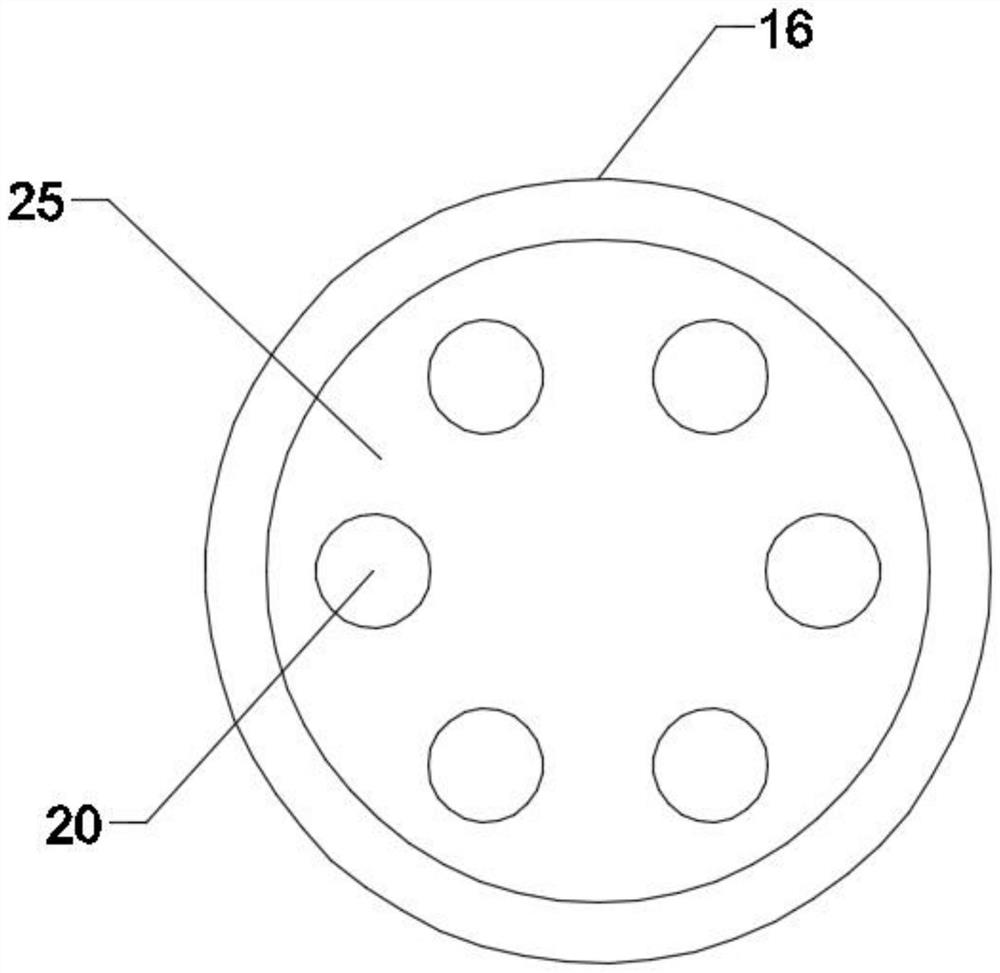

[0026] Such as Figure 1 to Figure 5 As shown, the present invention discloses an automatic vacuum pouring machine. The technical solution adopted is to include a stirring chamber 101, a vacuum pump 2, a first vacuum pipe 3, a feeding pipe 5, a raw material tank 8, a mold 12, a pouring chamber 13, and a motor 14 and a control circuit, there is a stirring mechanism in the stirring chamber 101, and the stirring chamber 101 is connected to the outlet pipe of the raw material tank 8 through the feed pipe 5, and the outlet pipe has a solenoid valve, and the stirring chamber 101 passes through the first vacuum tube 3 Connect the vacuum pump 2, the pouring chamber 13 is located below the mixing chamber 101, the inner shaft of the pouring chamber 13 is connected with a mold plate 11, the mold plate 11 has the mold 12 on it, and the mold plate 11 Driven by the motor 14, there is a microprocessor in the control circuit, and the microprocessor is electrically connected with the stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com