Load assembling mechanism and spatial load unfolding and folding device

A technology of assembling mechanism and load, which is applied in fixed devices, motor vehicles, mechanical equipment, etc., can solve the problems of difficult replacement, long-term scalability, and replaceable loads, etc., and achieves convenient replacement, good maintainability, and environmental adaptability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

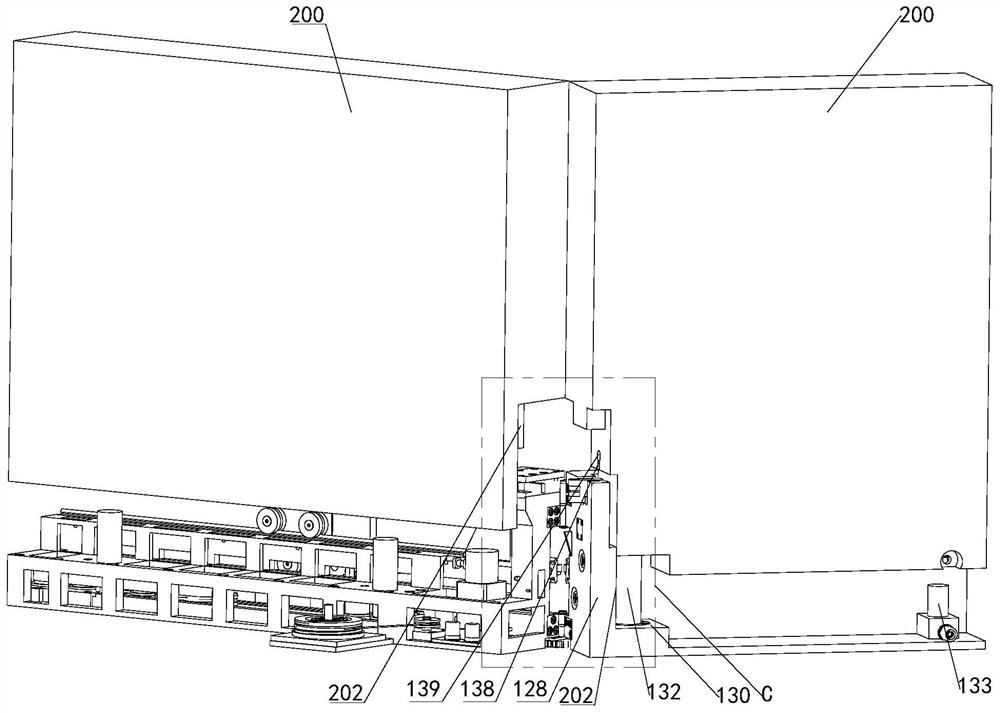

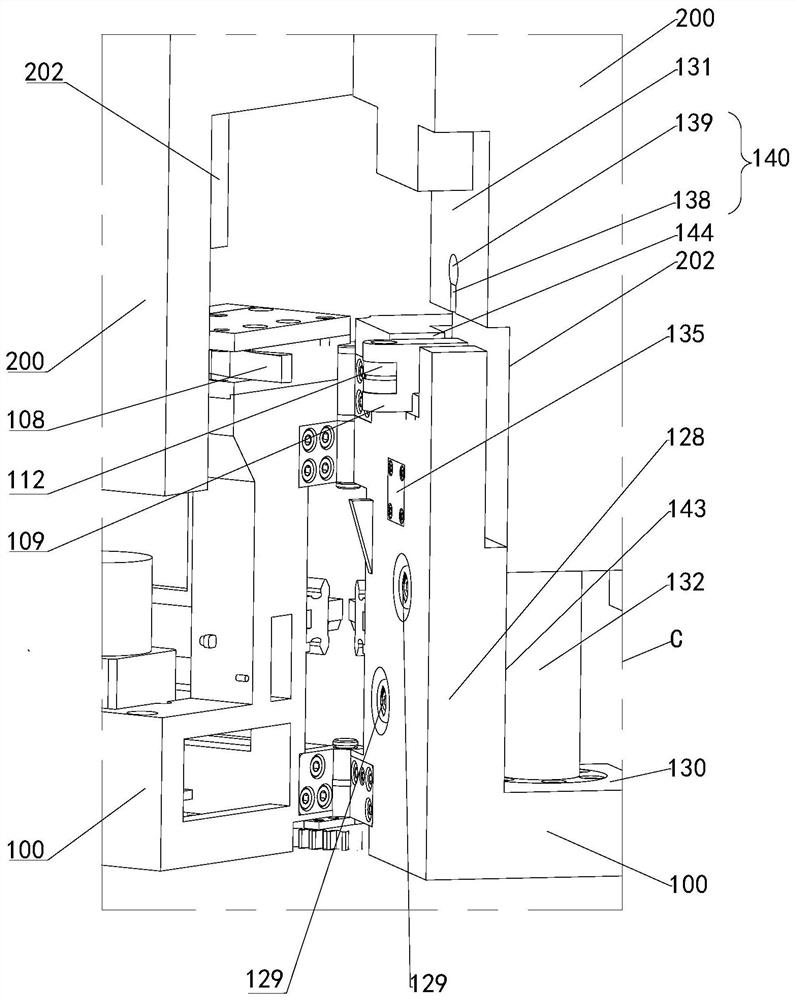

[0045] Such as Figure 1 to Figure 7 As shown, a load assembly mechanism of this embodiment includes a load body 200 and an unfolding platform 100, one side of the unfolding platform 100 is provided with a first stepped structure 124, and the horizontal stepped surface 130 of the first stepped structure 124 There is a guide post on it, and one end of the unfolding platform 100 is provided with a limit wall 128, and the limit wall 128 is provided with a captive screw 129, and the limit wall 128 is provided with an elastic limit piece 145; The bottom side of the load body 200 is provided with a second stepped structure 201 adapted to the first stepped structure 124, and the horizontal stepped surface 130 of the second stepped structure 201 is provided with a guide adapted to the guide column. hole, the bottom end surface of the load body 200 is provided with a limit slot 140 and a screw hole adapted to the elastic limit member 145 .

[0046] Such as Figure 6 and Figure 7 As...

Embodiment 2

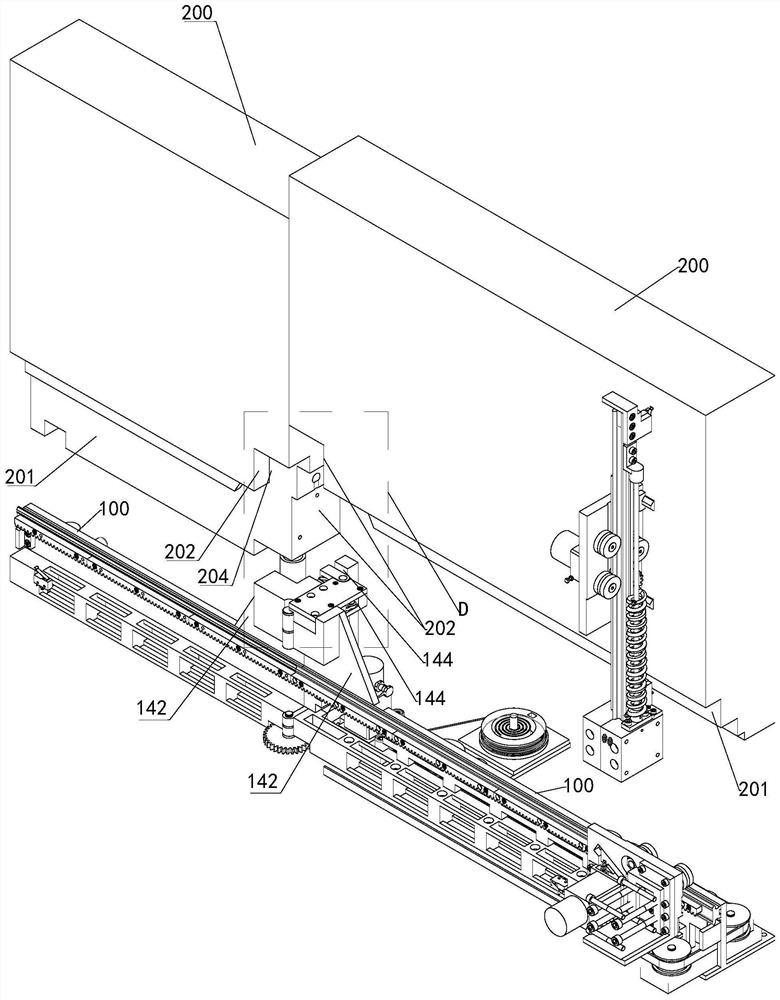

[0055] Such as Figure 8 ~ Figure 11 As shown, a space load deployment device of this embodiment includes the load assembly mechanism described in Embodiment 1, and also includes a deployment drive mechanism and a locking mechanism, and at least two of the deployment platforms 100 are hinged sequentially through hinges 122 The power part of the unfolding drive mechanism is installed on one of the two adjacent unfolding platforms 100, and the transmission gear 104 of the unfolding drive mechanism is rotatably connected to the hinges 122 of the two adjacent unfolding platforms 100. and connected with another deployment platform 100; the locking mechanism includes a latch 125 and a locking assembly 126, and the latch 125 and locking assembly 126 are respectively installed on two adjacent deployment platforms 100 The upper end face of the limiting wall 128; the power part of the unfolding drive mechanism is connected with the transmission gear 104 and drives the transmission gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com