Reinforced concrete for prestressed carbon fiber plate

A carbon fiber board and concrete technology, applied in the field of building materials, can solve the problems of poor concrete performance, low performance reliability, increased cost, etc., and achieve the effect of increasing strength and improving expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

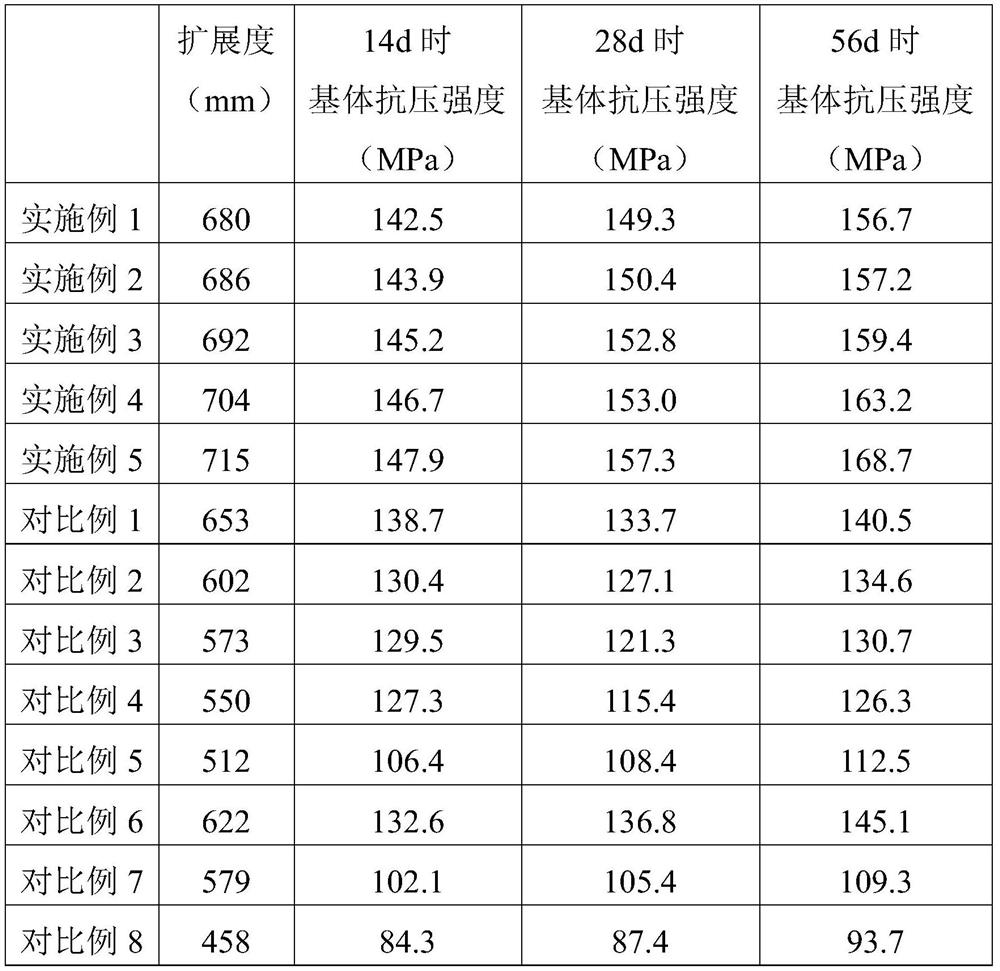

Examples

Embodiment 1

[0052] The reinforced concrete for the prestressed carbon fiber plate of the present embodiment includes the following raw materials in parts by weight:

[0053] Cement: 150 parts,

[0054] Water: 90 parts,

[0055] Clay: 25 parts,

[0056] Strengthening agent: 40 parts,

[0057] Polycarboxylate water reducer: 3 parts,

[0058] Dispersant: 5 parts.

[0059] In the reinforced concrete for the above-mentioned prestressed carbon fiber plate,

[0060] Described cement is P.O 42.5R portland cement;

[0061] The parameters of the clay are as follows:

[0062] SiO 2 The content is 55%, Al 2 o 3 The content is 35%, and the specific surface area is 10200m 2 / kg, particle size D 50 It is 5.5um.

[0063] In the reinforced concrete for the above-mentioned prestressed carbon fiber plate,

[0064] The model of the polycarboxylate water reducer is 412, purchased from Shenyang Xingzhenghe Chemical Co., Ltd.;

[0065] The model of the dispersant is WHDF-S, purchased from Shandong...

Embodiment 2

[0082] The reinforced concrete for the prestressed carbon fiber plate of the present embodiment includes the following raw materials in parts by weight:

[0083] Cement: 200 parts,

[0084] Water: 70 parts,

[0085] Clay: 35 parts,

[0086] Strengthening agent: 20 parts,

[0087] Polycarboxylate water reducer: 6 parts,

[0088] Dispersant: 1 part.

[0089] In the reinforced concrete for the above-mentioned prestressed carbon fiber plate,

[0090] Described cement is P.O 42.5R portland cement;

[0091] The parameters of the clay are as follows:

[0092] SiO 2 The content is 60%, Al 2 o 3 The content is 40%, and the specific surface area is 14100m 2 / kg, particle size D 50 It is 6.5um.

[0093] In the reinforced concrete for the above-mentioned prestressed carbon fiber plate,

[0094] The model of the polycarboxylate water reducer is 412, purchased from Shenyang Xingzhenghe Chemical Co., Ltd.;

[0095] The model of the dispersant is WHDF-S, purchased from Shandong ...

Embodiment 3

[0112] The reinforced concrete for the prestressed carbon fiber plate of the present embodiment includes the following raw materials in parts by weight:

[0113] Cement: 160 parts,

[0114] Water: 85 parts,

[0115] Clay: 28 parts,

[0116] Strengthening agent: 35 parts,

[0117] Polycarboxylate water reducer: 3 parts,

[0118] Dispersant: 5 parts.

[0119] In the reinforced concrete for the above-mentioned prestressed carbon fiber plate,

[0120] Described cement is P.O 42.5R portland cement;

[0121] The parameters of the clay are as follows:

[0122] SiO 2 The content is 55%, Al 2 o 3 The content is 35%, and the specific surface area is 10200m 2 / kg, particle size D 50 It is 5.5um.

[0123] In the reinforced concrete for the above-mentioned prestressed carbon fiber plate,

[0124] The model of the polycarboxylate water reducer is 412, purchased from Shenyang Xingzhenghe Chemical Co., Ltd.;

[0125] The model of the dispersant is WHDF-S, purchased from Shandong...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap