Wind power tower drum landing control system

A wind power tower and control system technology, applied in wind power generation, electrical components, wind engines, etc., can solve problems such as low-temperature noise, failure to start, and increased thermal noise of electronic equipment, and achieve improved stability and stable operating temperature range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

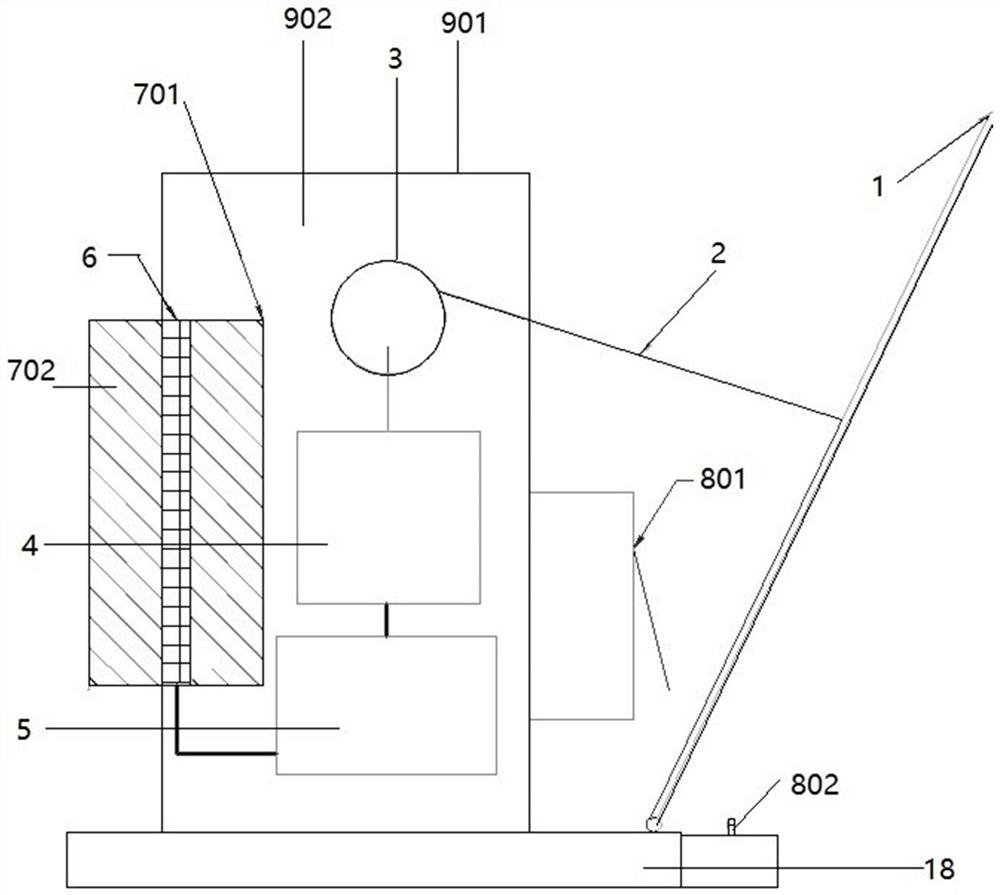

[0036] This embodiment provides an automatic cover assembly of a climbing avoidance device, such as figure 1 with figure 2 shown.

[0037]A plurality of platforms 18 are installed on the climbing ladder in the wind turbine tower, and the plurality of platforms 18 are arranged at intervals along the height direction of the wind turbine tower, and each platform 18 is provided with a passage for passing through the body of the climbing avoidance device. The opening and closing of the channel is realized by the controller controlling the cover.

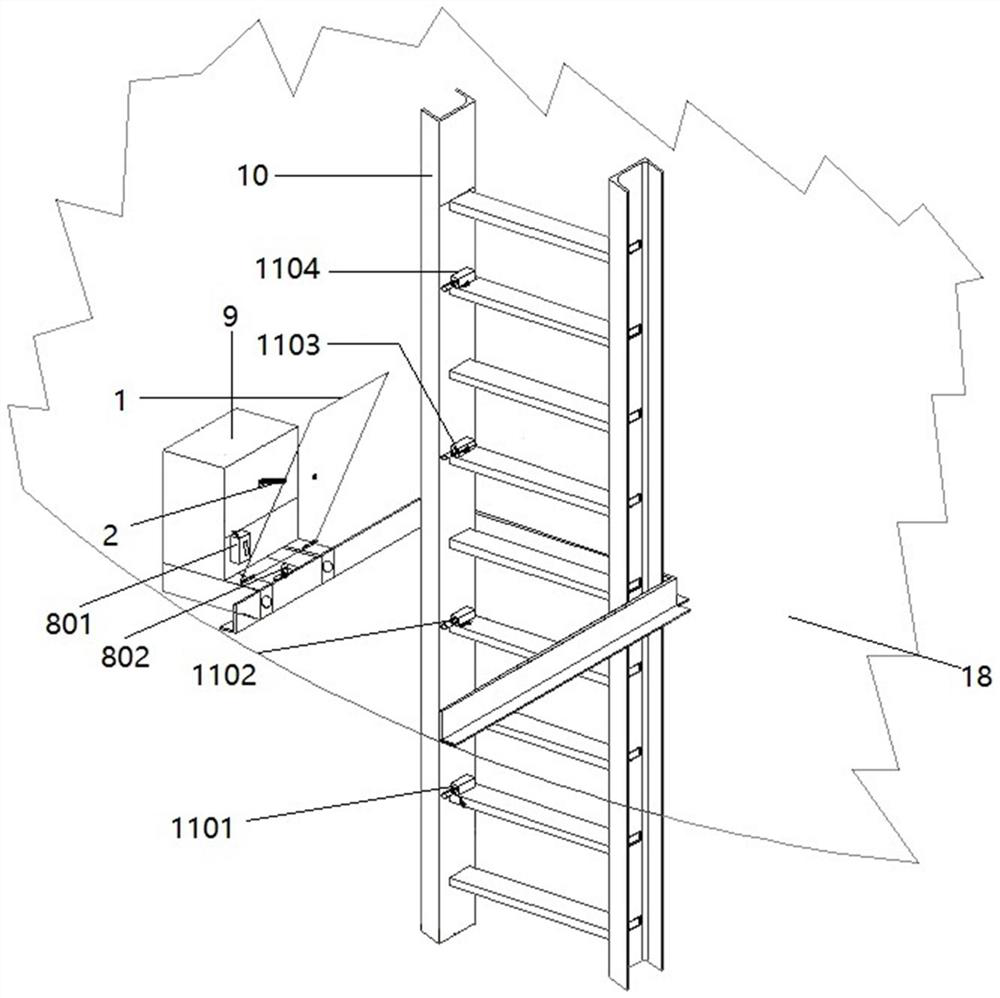

[0038] The free-climber includes a ladder track 10 for the free-climber, a vehicle body for the free-climber, an automatic cover assembly, a limiting device 8 and a main control box.

[0039] The ladder track 10 of the climber-free device is provided with four travel switches 11 equidistant from the first travel switch 1101, the second travel switch 1102, the third travel switch 1103 and the fourth travel switch 1104 on the ladder rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com