Cooperative operation test platform capable of supporting basic research on digital twin fully mechanized coal mining face

A fully-mechanized mining face and operation test technology, applied in the field of collaborative operation test platform, can solve problems such as difficulty in supporting digital twin face, single function, lack of practicability and implementability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

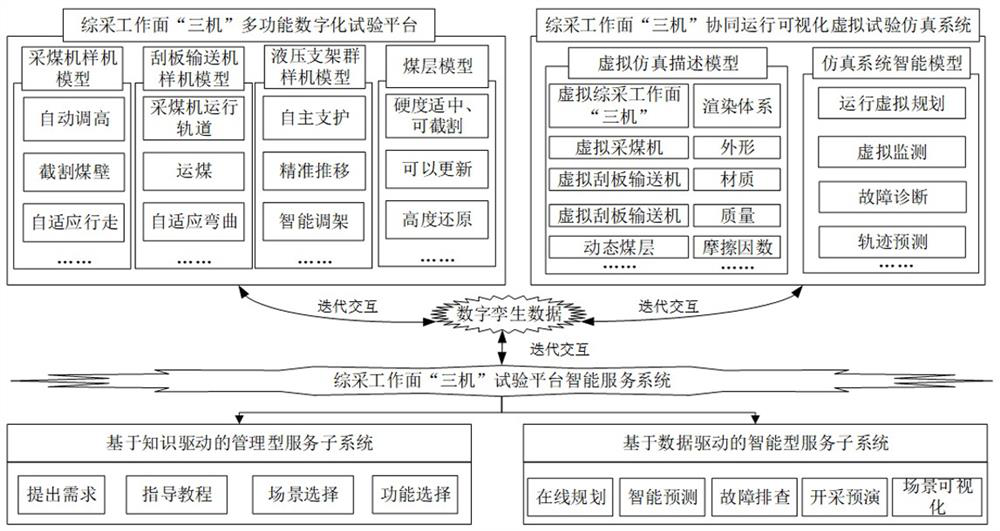

[0044] The collaborative operation test platform described in this embodiment that can support the basic research of the digital twin fully mechanized mining face includes a physical model, a virtual model, digital twin data and a test platform service system. It can carry out operation reproduction, mining preview and fault warning for the mining process of the fully mechanized mining face, and realizes the real-time interaction between the virtual prototype test platform and the physical prototype test platform. The establishment of this test platform can conduct research on common engineering problems in the mine, And create a research environment and platform support for the application of some new technologies.

[0045] Such as figure 1 As shown, the above-mentioned digital collaborative operation test platform that can support the multi-functional basic research of the digital twin fully mechanized mining face includes the "three machines" multifunctional digital test pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com