Intensive bus duct with L-shaped aluminum heat dissipation plate and copper conductor

A copper conductor and aluminum heat dissipation technology, applied in the field of power transmission, can solve problems such as low heat dissipation efficiency, conductor aging, and increased energy consumption, and achieve the effects of improving heat dissipation and cooling, increasing service life, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

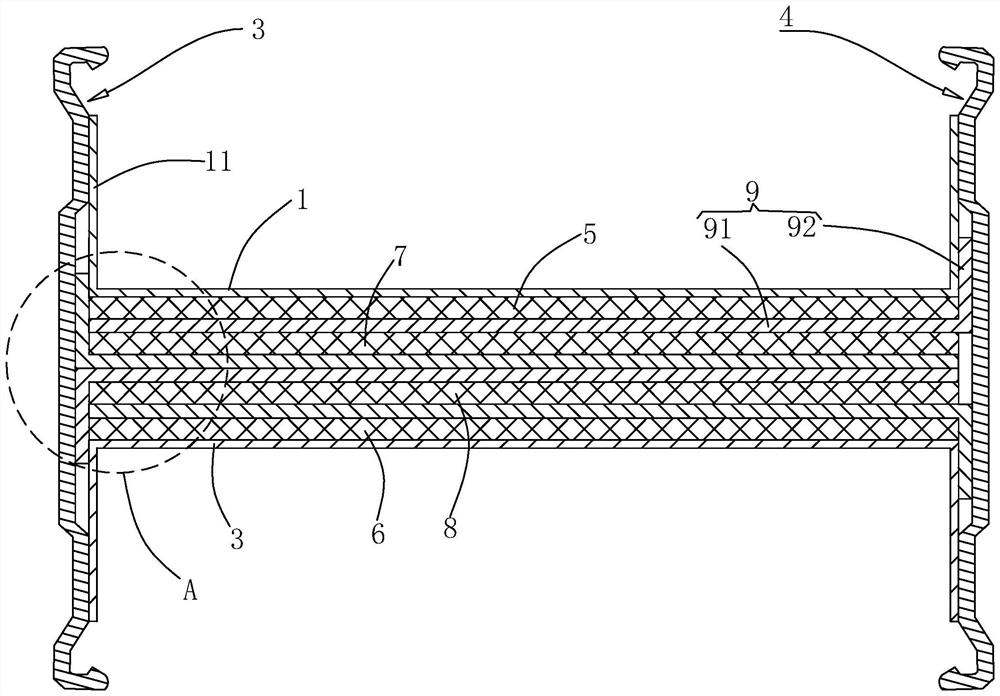

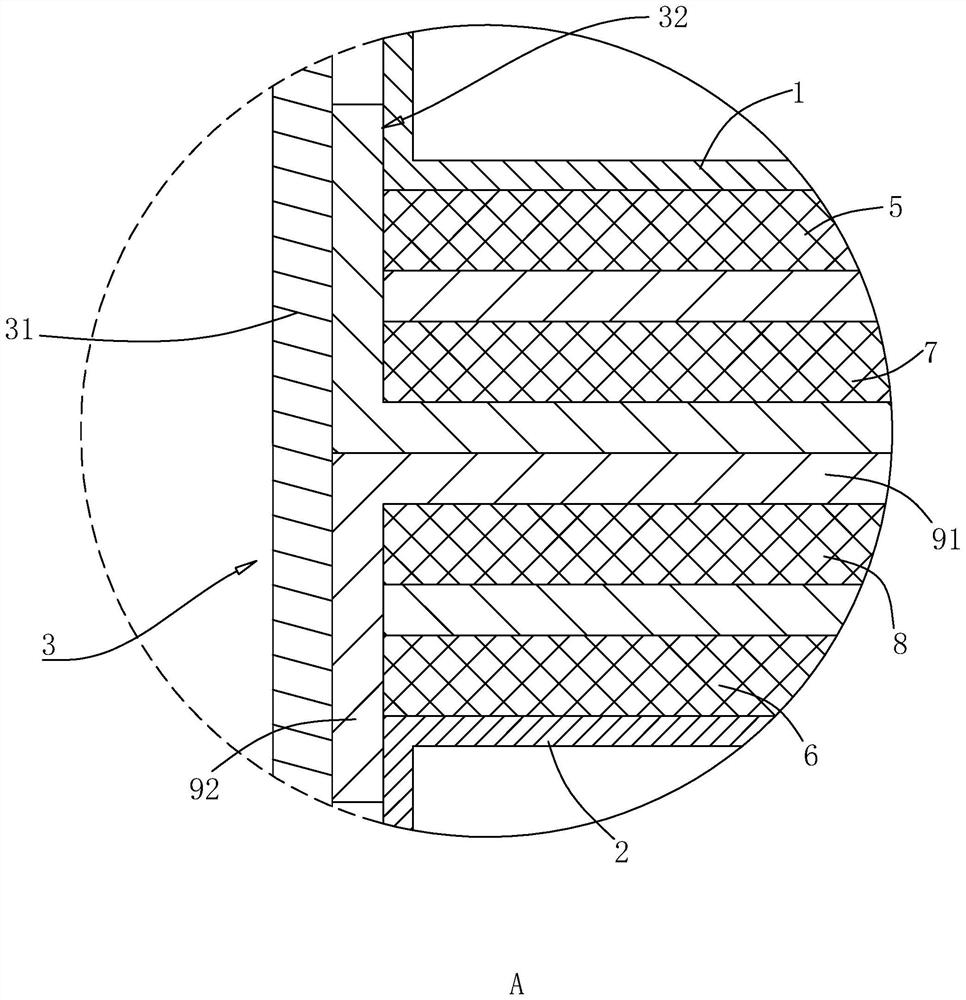

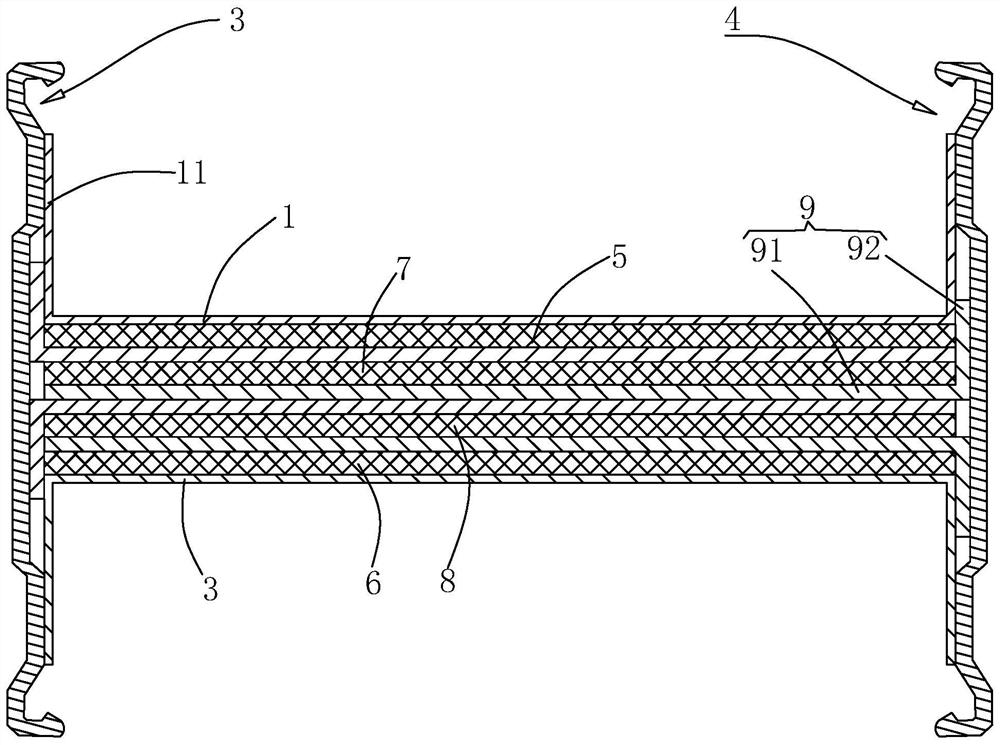

[0047] refer to image 3 with Figure 4 , this embodiment discloses another way of crossing distribution of a plurality of aluminum plates 9: the heat dissipation part 92 on the aluminum plate 9 between the L1 phase copper conductor 5 and the L2 phase copper conductor 7 is attached to the left side plate 3, then the L2 phase The heat dissipation part 92 on the aluminum plate 9 close to the L3 phase copper conductor 8 among the two aluminum plates 9 between the copper conductor 7 and the L3 phase copper conductor 8 is also attached to the left side plate 3, and the L2 phase copper conductor 7 and the L3 phase copper conductor The heat dissipation portion 92 of the other aluminum plate 9 in the two aluminum plates 9 between the conductors 8 is attached to the right side plate 4, and the heat dissipation portion 92 of the aluminum plate 9 between the N phase copper conductor 6 and the L3 phase copper conductor 8 is also connected to the right side plate 9. Side panels 4 fit toge...

Embodiment 3

[0051] Refer to 5 and Image 6 , in this embodiment, two symmetrical heat conduction plates 10 are provided between the L2 phase copper conductor 7 and the L3 phase copper conductor 8, and the heat conduction plate 10 is attached to the heat conduction portion 91 away from the L2 phase copper conductor 7 or the L3 phase copper conductor 8 One side of the heat conduction plate 10, and both ends of the heat conduction plate 10 are fixedly connected with a heat dissipation plate 101, the heat dissipation plate 101 is perpendicular to the heat conduction plate 10 so that the heat conduction plate 10 and the two heat dissipation plates 101 form a U-shaped structure, and the heat dissipation plate 101 is attached to the heat dissipation The portion 92 is close to the side of the left side plate 3 or the right side plate 4; the heat conduction plate 10 and the heat dissipation plate 101 play the role of auxiliary heat dissipation, thereby further improving the effect of heat dissipati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com