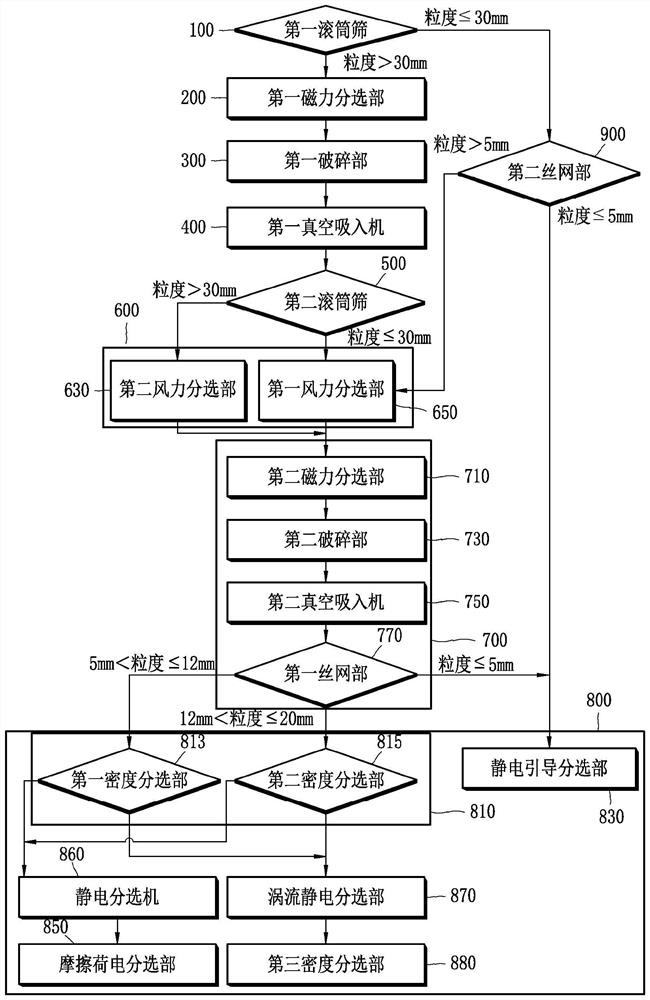

Complex sorting system and complex sorting method for sorting automobile shredder residue using trommel

A technology for scrapped cars and sorting systems, applied in chemical instruments and methods, using airflow to separate solids from solids, filtering, etc., can solve environmental pollution, insufficient landfills, and uneven particle size of scrapped car residues etc. to achieve the effect of improving removal efficiency and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036]Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0037] The advantages, features and methods for achieving them of the present invention will become clear with reference to the following embodiments described in detail with reference to the accompanying drawings. However, the present invention is not limited to the embodiments disclosed below, and can be realized through different implementation modes. However, the disclosure of this embodiment for the present invention becomes complete so that those of ordinary skill in the art to which the present invention belongs can fully understand the present invention category. Furthermore, the present invention is limited only by the scope of the claims.

[0038] In addition, in the process of describing the present invention, when it is judged that the content of related known technologies and the like may obscure the gist of the present inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com