Method and device for avoiding corner overburning slag adhering defect based on sharp corner technology and arc technology, processor and storage medium thereof

A kind of technology and sharp corner technology, which is applied in the field of avoiding corner over-burning and slag defects, can solve the problems of high scrap rate of cutting workpieces, corner over-burning and slag, affecting the processing quality of workpieces, etc., so as to avoid excessive laser power and meet cutting requirements. Quality requirements, solving the effect of easy over-burning and hanging slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

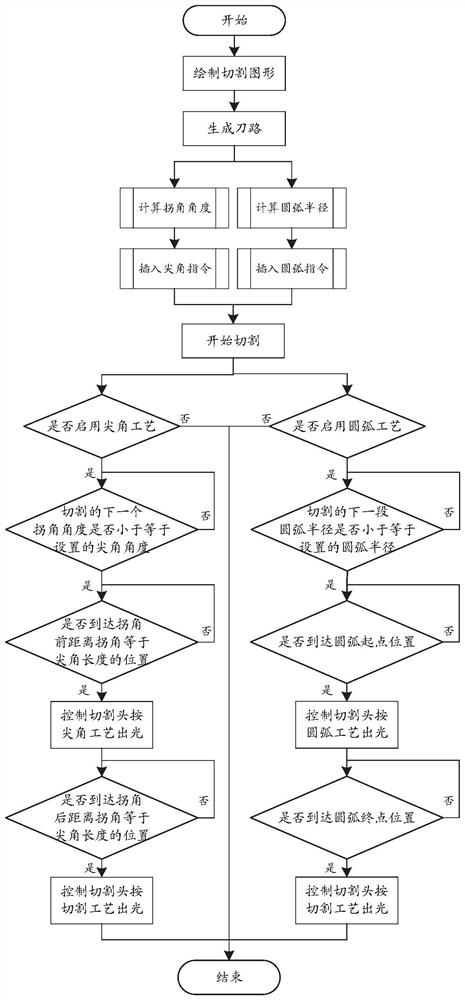

[0053] In the numerical control system of the present invention, the method for avoiding the corner over-burning and slag-hanging defects based on the sharp-corner process and the circular-arc process comprises the following steps:

[0054] (1) Draw cutting graphics and generate tool paths;

[0055] (2) Judging whether to prepare sharp corner technology or circular arc technology, if it is sharp corner technology, then continue to step (3); otherwise, continue to step (4);

[0056] (3) Calculate the sharp corner angle of each inflection point, insert the command of sharp corner technology, and continue to step (5);

[0057] (4) Calculate the radius length of each section of arc, insert the instruction of arc technology, and continue step (5);

[0058] (5) Control the laser cutting head to move according to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com