Fixture for machining steam seal teeth and two shoulders on steam inlet and outlet sides of marine blade and using method

A technology for sealing teeth and processing ships, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc. Problems such as non-uniform profile on the steam outlet side of the intermediate body and rapid tool wear, etc., can avoid unsatisfactory tool connection, large allowance and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

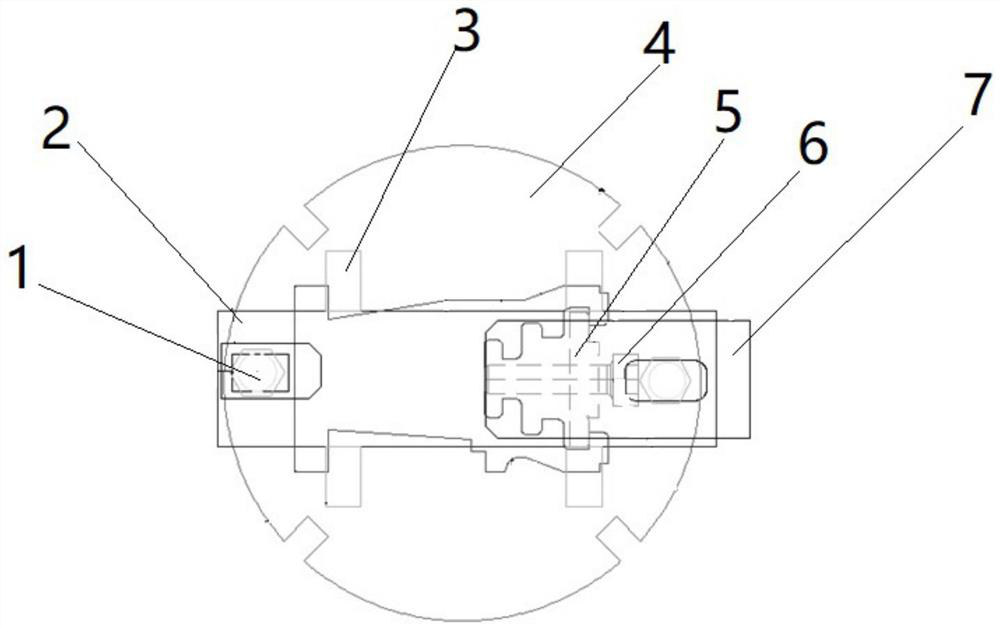

[0021] Specific implementation mode one: combine figure 1 Describe this embodiment, a fixture for processing marine blade inlet and outlet steam seal teeth and two shoulders described in this embodiment includes No. 1 pressure plate 1, base 2, connecting plate 4, blade root positioning block 5, locking bolt 6 and No. 2 platen 7;

[0022] A base 2 is provided on the end surface of the connection plate 4, and a threaded hole is respectively provided at both ends of the upper surface of the base 2, and a locking stud is arranged inside each threaded hole, and a No. Pressing plate 1, No. 2 pressing plate 7 is arranged on the other locking stud, and the top of each locking stud is provided with a locking nut, and the middle part of the upper surface of the base 2 is provided with a blade root positioning block 5, and the blade root A threaded hole is provided on the side of the root positioning block 5, and a locking bolt 6 is provided inside the threaded hole;

[0023] In this s...

specific Embodiment approach 2

[0025] Specific implementation mode two: combination figure 1 Describe this embodiment. This embodiment is a further limitation on the fixture described in Embodiment 1. A fixture for processing marine blade steam seal teeth and shoulders on the inlet and outlet steam sides described in this embodiment. The base 2 A reinforcing rib 3 is provided between the side of the connecting plate 4 and the end face;

[0026] In this specific embodiment, a reinforcing rib 3 is provided between the side surface of the base 2 and the end surface of the connecting plate 4 to improve the stability of the device.

specific Embodiment approach 3

[0027] Specific implementation mode three: combination figure 1 Describe this embodiment, this embodiment is a further limitation on the fixture described in the first embodiment, a kind of fixture for processing the inlet and outlet steam seal teeth and shoulders of the marine blade described in this embodiment, the No. 1 The width of pressing plate 1 is less than the width of No. 2 pressing plate 7;

[0028] In this specific embodiment, the width of the No. 1 pressing plate 1 is smaller than that of the No. 2 pressing plate 7 to improve the accuracy of blade clamping.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com