Bridge type material conveying line

A technology for conveying lines and materials, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of short transmission distance, long transmission distance, and inability to realize cross-regional transmission, etc., to improve material transportation efficiency, Efficient operation, solving the effect of short transmission distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

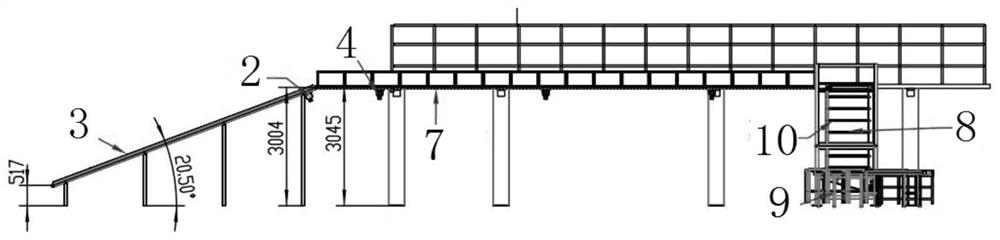

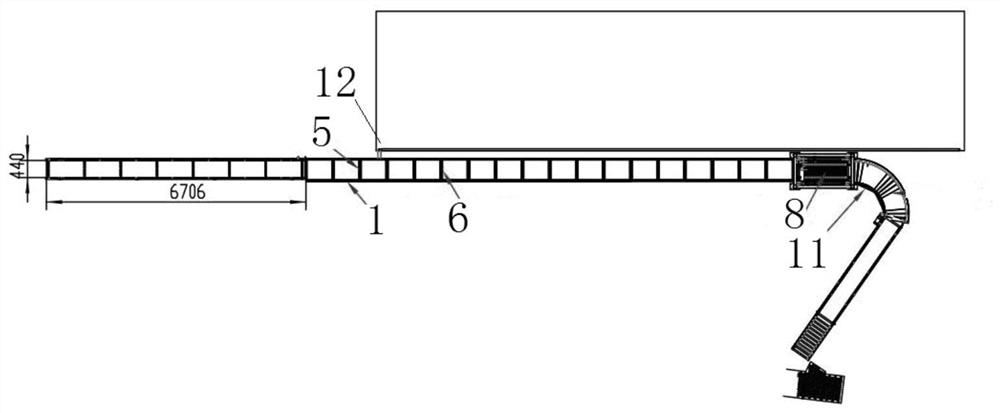

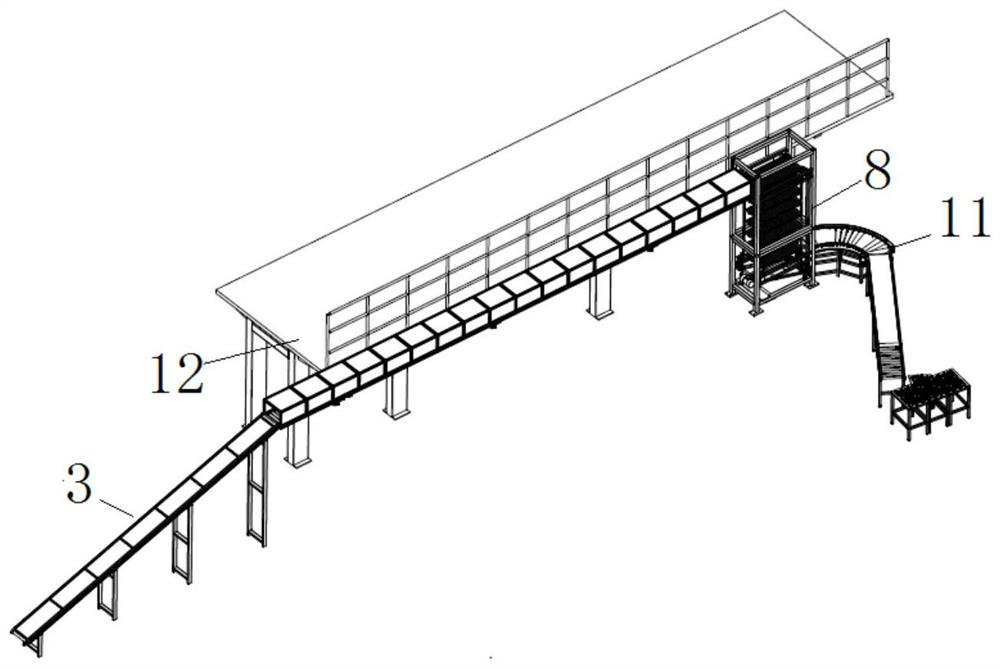

[0029] like Figure 1 to Figure 7 As shown, the bridge-type material conveying line includes a climbing belt 3, a conveying bridge 1, a material lifting mechanism 8, and a turning conveyor frame 11; the climbing belt is used for conveying and raising materials; the conveying bridge is used for cross-regional conveying of materials, The conveying bridge is provided with a roller conveying structure for conveying materials and a roller driving motor 4 for driving the operation of the roller conveying structure. One end of the roller conveying structure on the conveying bridge is connected to the top of the climbing belt; the material lifting mechanism is used to transport The material on the bridge is conveyed down, and the top of the material lifting mechanism is docked with the other end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com