Wide-temperature-range gradient multi-layer self-adhesive constrained damping material and preparation method thereof

A constrained damping, self-adhesive technology, applied in the field of damping materials, can solve the problems of narrow effective damping temperature range, narrow application range and high characteristic requirements of composite damping materials, and achieve the goal of improving the effective damping temperature range, widening the use temperature range, improving the The effect of damping values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Preparation of low-temperature damping layer material (IIR1): choose butyl rubber as the base material, add 100phr short-chain polyisobutylene, and knead at 130°C for 120min to obtain low-temperature damping material. After testing, its loss peak at -34.2°C is 2.22, the glass transition temperature is -66.7℃.

[0030] Preparation of intermediate temperature damping layer material (IIR2): select butyl rubber as the base material, add 100phr long-chain polyisobutylene and 100phrP125 petroleum resin, mix at 130°C for 120min, and obtain intermediate temperature damping material. The loss peak is 1.9, and the glass transition temperature is -49.3°C.

[0031] Preparation of high-temperature damping layer material (IIR3): select butyl rubber as the base material, add 100phr long-chain polyisobutylene and 400phrP125 petroleum resin, and mix at 130°C for 120min to obtain high-temperature damping material. The loss peak is 2.7, and the glass transition temperature is -8.9°C.

...

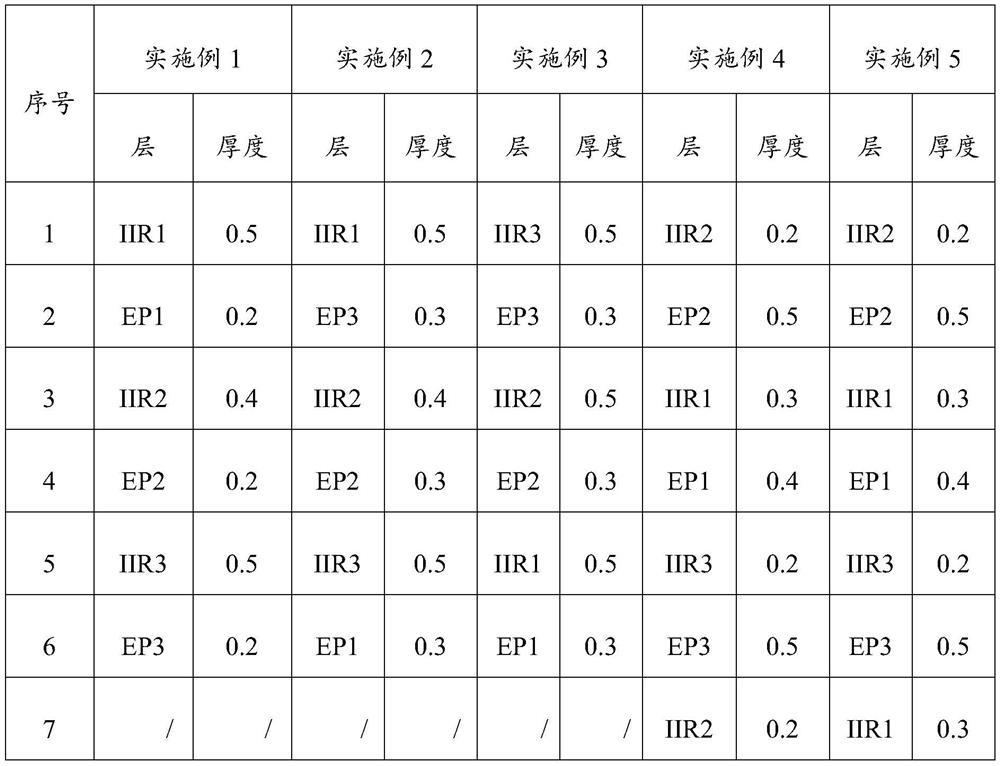

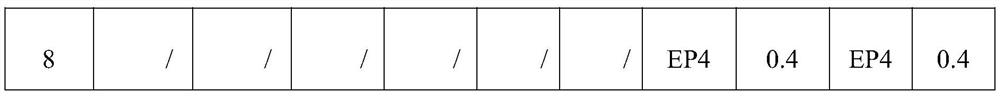

Embodiment 1-5

[0036] Table 1 shows the specific structure of the multi-layer damping material in Examples 1-5, wherein the serial number 1 indicates the layer close to the base steel, the serial number 2 is the second layer, and so on. The unit of the thickness of each layer is mm.

[0037] The multilayer damping material of table 1 embodiment 1-5

[0038]

[0039]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com