Technological method for offshore platform shipborne circulating well washing and return liquid purification treatment

An offshore platform, purification and treatment technology, applied in the direction of flushing wellbore, earthwork drilling, wellbore/well components, etc. It is easy to pollute a large area, it is beneficial to navigation safety, and the effect of reducing the amount of sewage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

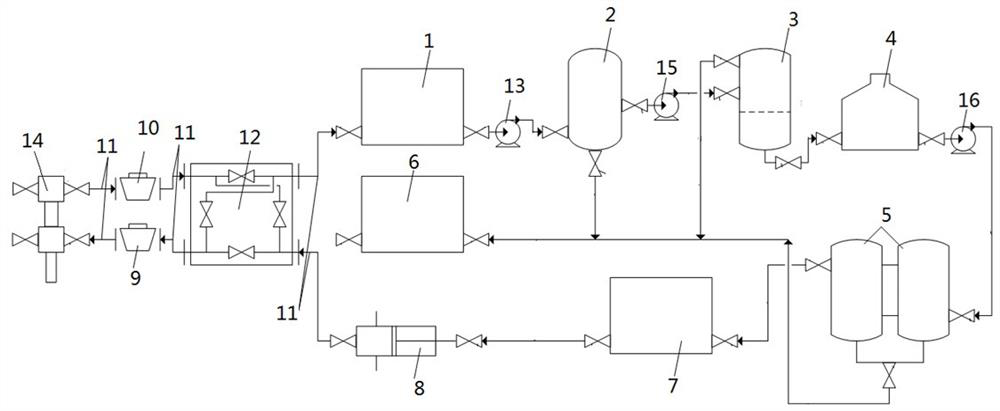

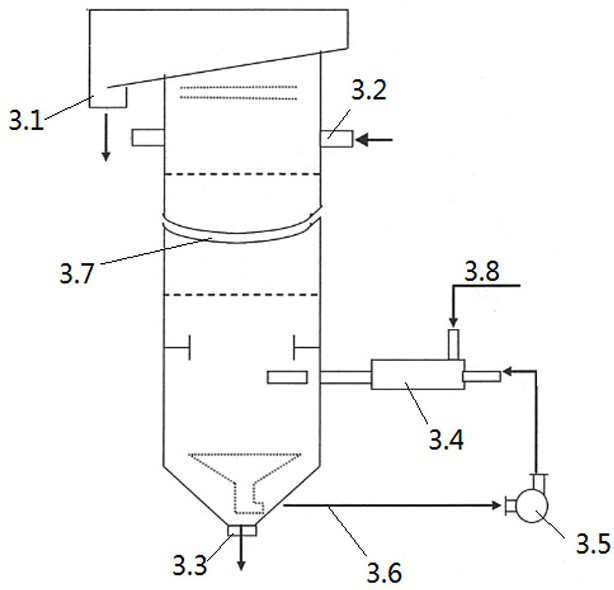

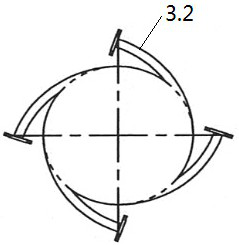

[0035] Embodiment 1, with reference to Figure 1-4 , a ship-borne circulating well flushing and liquid return treatment device for offshore platform water injection wells mentioned in the present invention, including a special well flushing ship, a camera is installed on the special well flushing ship, and a first-level buffer is also arranged on the special well flushing ship Tank 1, settling tank 2, oil-water separator 3, secondary buffer tank 4, fine filter 5, sewage tank 6, clean water tank 7, marine well washing pump skid 8, first outlet cock valve 9, second outlet cock Valve 10, high-pressure hose 11, front and back washing skid 12, first lift pump 13, second lift pump 15 and third lift pump 16;

[0036] The outlet on the upper side of the Christmas tree 14 is connected to the inlet of the front and back washing skid 12 through the high-pressure rubber hose 11, the outlet of the front and back washing skid 12 is connected to the inlet of the first-stage buffer tank 1 thr...

Embodiment 2

[0050] Embodiment 2: refer to Figure 5 , the present invention refers to a process method for circulating well flushing and return liquid on board a water injection well on an offshore platform. During the well flushing process, a turbidimeter is used to measure that the return liquid is oily sewage without particulate matter, and the equipment and connecting pipelines can be readjusted. .

[0051] Compared with Embodiment 1, the difference is that the secondary buffer tank 4 and the fine filter 5 are not connected.

[0052] The specific working process is as follows:

[0053] Step 1: The return fluid from well flushing enters the first-stage buffer tank 1 through the high-pressure rubber hose 11 through the second outlet cock 10 and the positive and negative flushing skid 12. After entering the settling tank 2, relatively large impurities are deposited at the bottom of the settling tank 2. The high-pressure well flushing fluid of the injection well is pressurized by the se...

Embodiment 3

[0056] Embodiment 3, with reference to Image 6 , the present invention refers to a process method for circulating well washing and return liquid purification treatment on board the offshore platform. During the well washing process, a turbidity meter is used to measure that the return liquid is muddy or sedimentary sewage. When it does not contain oil, it can be re- Adjust equipment.

[0057] Compared with Example 1, the difference is that the oil-water separator 3 and the secondary buffer tank 4 are omitted.

[0058] When using it specifically:

[0059]The flushing liquid returns to the primary buffer tank 1 through the high-pressure hose 11 through the second outlet plug valve 10 and the positive and negative washing skid 12. After decompression and pre-sedimentation, the first lift pump 13 is turned on and enters the settling tank through the pipeline. 2. Larger impurities are deposited at the bottom of the settling tank 2, and the liquid returned from well washing is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com