Integrated device for automobile fuel steam desorption

A fuel vapor, integrated device technology, which is applied to the charging system, adding non-fuel substances to fuel, engine components, etc. The effect of saving production costs and convenient production and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1: The embodiment of this application discloses an integrated device for desorption of automobile fuel vapor.

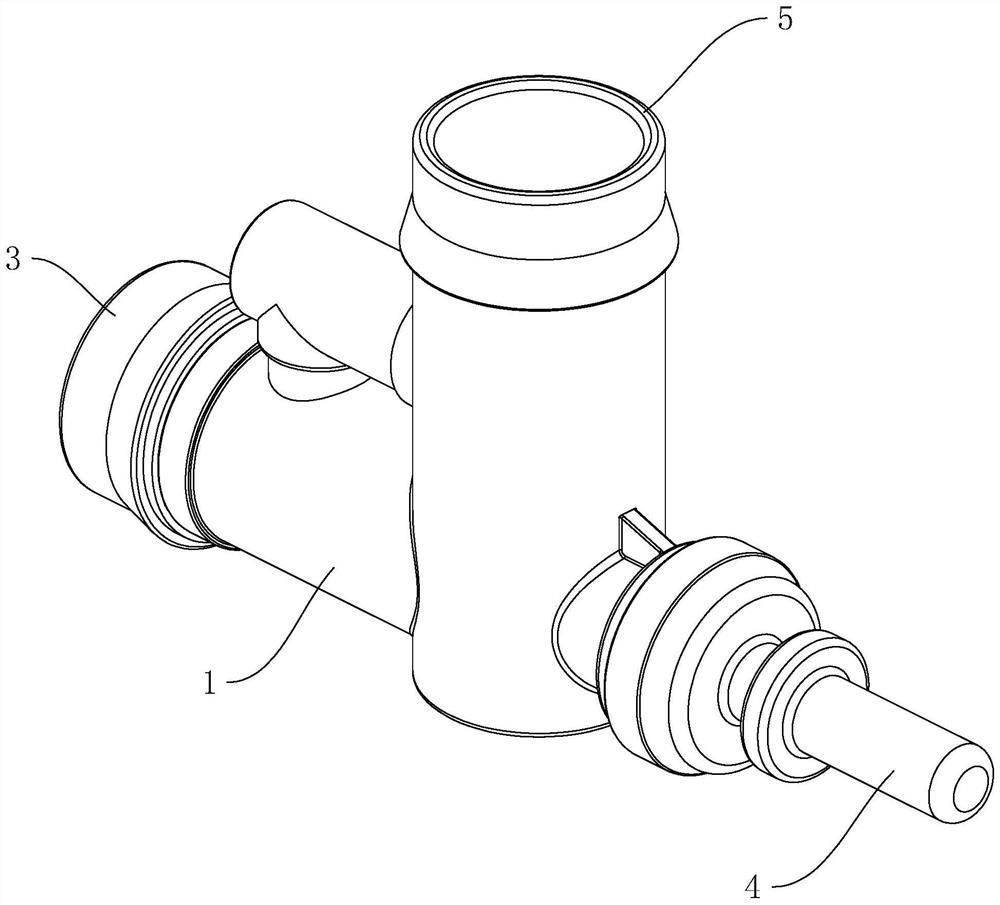

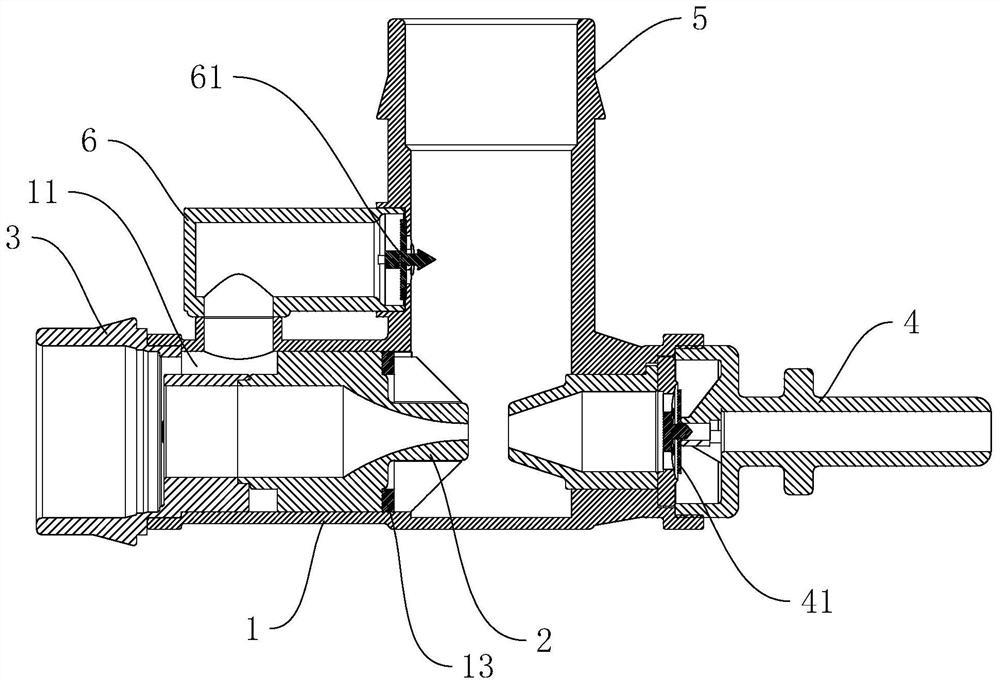

[0050] refer to figure 1 , figure 2 , the integrated device includes a Venturi tube 1 , a Venturi structure 2 , an installation end 3 , an installation through pipe 4 and an installation end pipe 5 .

[0051] refer to figure 1 , figure 2 The venturi tube 1 is arranged horizontally, and the installation end pipe 5 is vertically connected to the top of the venturi tube 1, and forms a tee pipe with the venturi tube 1, and is used to communicate with the carbon tank of the car at the same time. Wherein the installation end 3 and the installation through pipe 4 are respectively arranged at the two ends of the venturi tube 1, and are used to communicate with the position between the intake manifold and the throttle valve and the automobile air filter respectively. And the installation end 3 is a quick connector, and the installation through pipe 4 i...

Embodiment 2

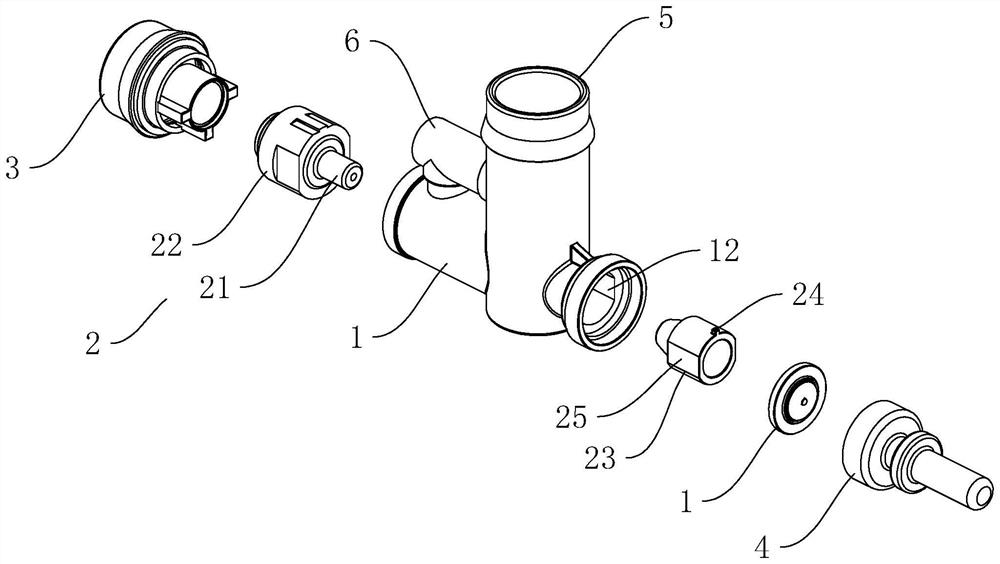

[0073] Embodiment 2: The embodiment of this application discloses an integrated device for desorption of automobile fuel vapor.

[0074] refer to Figure 5 , the difference from Embodiment 1 is that the shrink tube 21 includes a main pipe 216 and a connecting block 217 . One end of the main pipe 216 is connected to the installation head 3 , and the other end extends into the venturi 1 , and the collar 22 and the guide plane 25 are integrally formed on the outer wall of the main pipe 216 .

[0075] refer to Figure 5 , wherein at least one connection block 217 is provided and arranged at intervals. The connection block 217 is arranged between the outer wall of the main pipe 216 and the inner wall of the installation terminal 3 . Wherein the installation end 3, the main pipe 216 and the connection block 217 are integrally formed to realize one-time injection molding of the installation end 3, the main pipe 216 and the connection block 217, which is convenient for production a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com