Pipe orifice butt joint method and device of concrete pipeline

A docking device and concrete technology, which is applied in the direction of pipe/pipe joint/fitting, sleeve/socket connection, passing components, etc., can solve the problems of sealing ring failure, time-consuming, labor-intensive, unpredictable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

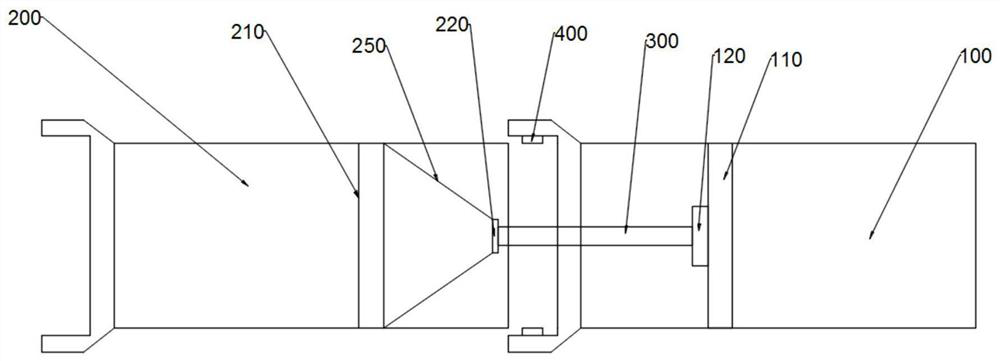

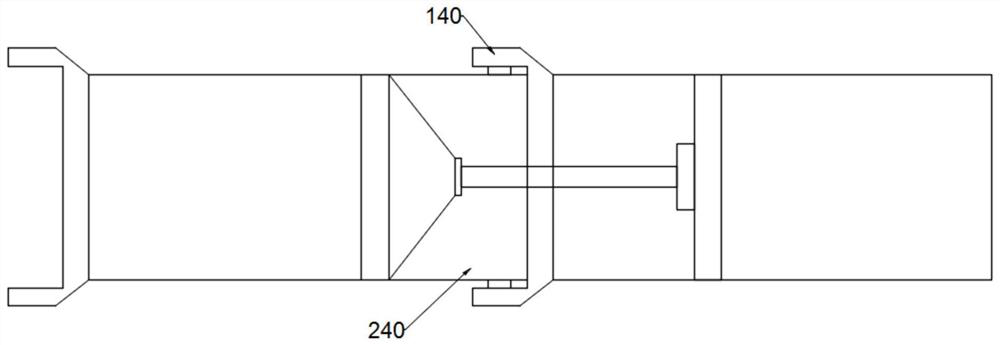

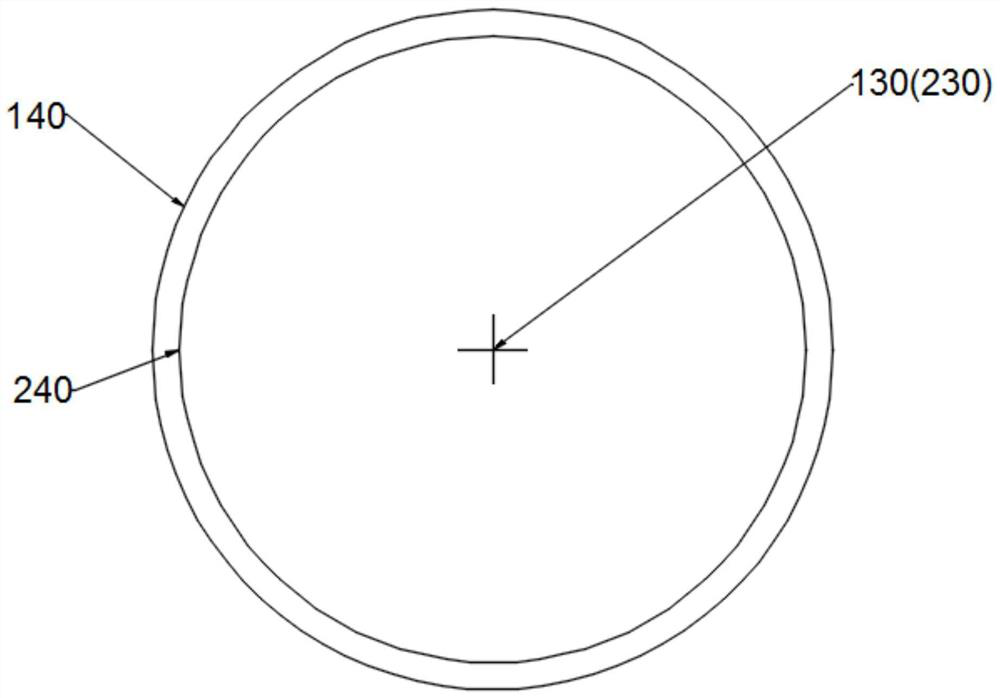

[0023] A detailed description will be given below in conjunction with the accompanying drawings.

[0024] figure 1 and figure 2 As shown, the present invention provides a method and device for butt jointing of concrete pipelines, which are used for connecting deep underground or semi-buried pipelines in large-scale engineering construction. At present, the large-scale pipelines commonly used in engineering are composed of prefabricated concrete pipelines connected end to end. Prefabricated concrete pipelines are tubular structures formed by bundling concrete or steel bars into columns and then poured. Generally speaking, the same batch or the same type of concrete The pipes have the same pipe length and pipe diameter parameters. During construction, the construction party needs to arrange and connect several selected types of concrete pipes in an end-to-end manner to form an overall pipe structure. The radial direction of the pipe is predetermined. The design direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com