Steam pipeline drainage method and system capable of responding in advance, equipment and medium

A technology of steam pipes and steam pipes, which is applied in the direction of mechanical equipment, steam traps, etc., can solve problems such as water hammer, inability to respond to poor operating conditions of the pipe network in time, and inability to discharge condensed water, etc., to achieve the effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

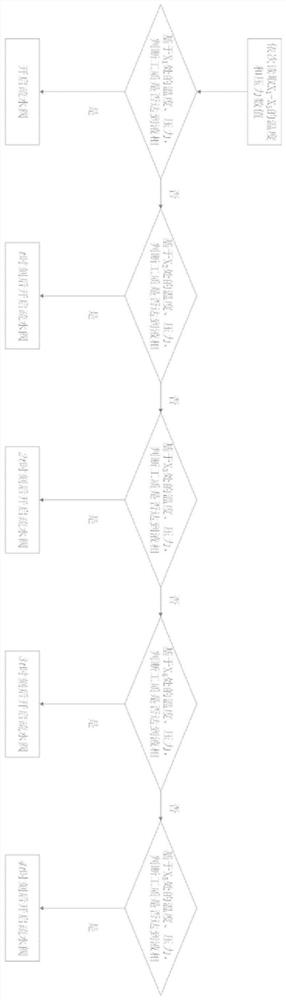

[0028] Such as figure 1 Shown, be the steam pipeline drainage method of early response described in the present invention, comprise the following process:

[0029] Divide the steam pipe network into a plurality of measurement points, the number of measurement points in this embodiment is five, which is X 1 、X 2 、X 3 、X 4 and x 5 , to obtain the temperature and pressure of the steam in the pipeline at each measurement point in real time.

[0030] The adjacent spacing of all measurement points is the same, and the adjacent spacing is 500m; X 1 、X 2 、X 3 、X 4 and x 5 Arranged in sequence from the downstream of the steam pipe network to the upstream, the closest measurement point X on the downstream of the steam pipe network 1 Located at trap location.

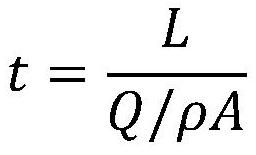

[0031] An additional flowmeter is installed in the pipeline at each measurement point to measure the mass fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com