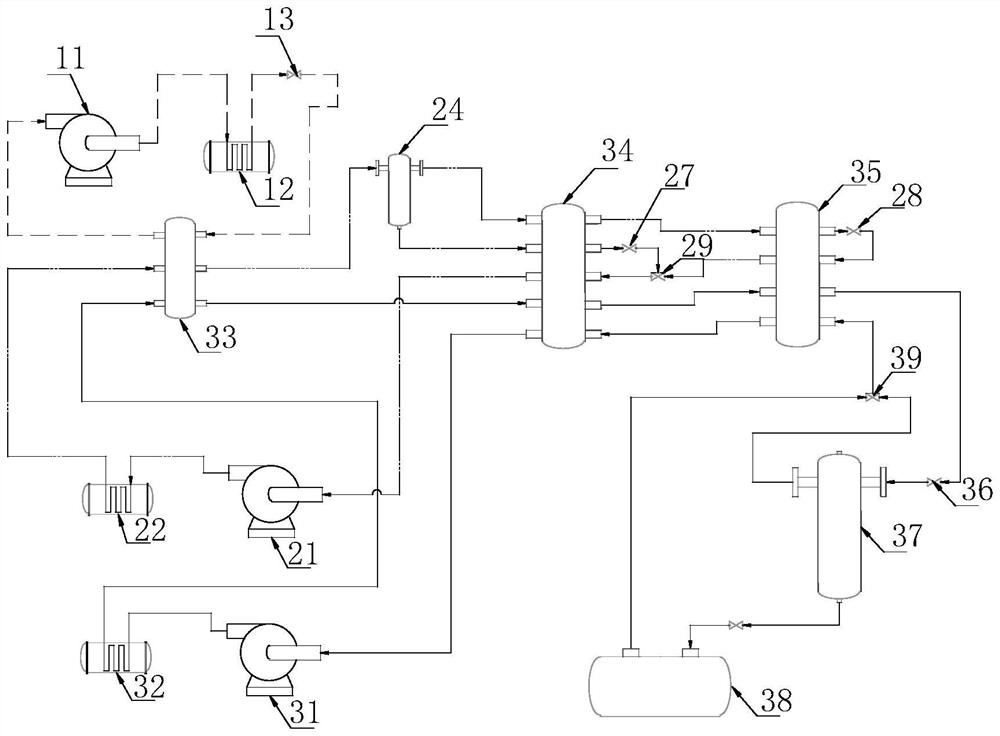

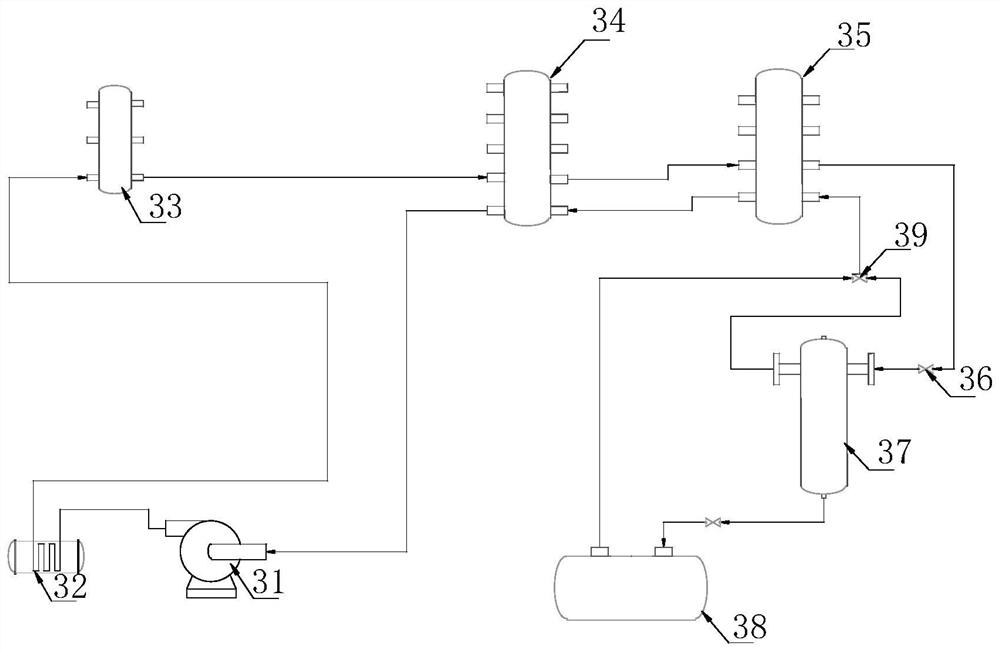

BOG reliquefaction circulating system for LNG (Liquefied Natural Gas) ship based on mixed working medium refrigeration technology

A technology for mixing working fluids and LNG ships, which is applied in refrigeration and liquefaction, liquefaction, refrigerators, etc., and can solve the problems of ineffective utilization of mixed refrigerant and BOG cold energy, low energy efficiency of reliquefaction system, and reduced system reliability. , to ensure system reliability and equipment sources, facilitate system layout, and reduce pipeline layout.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

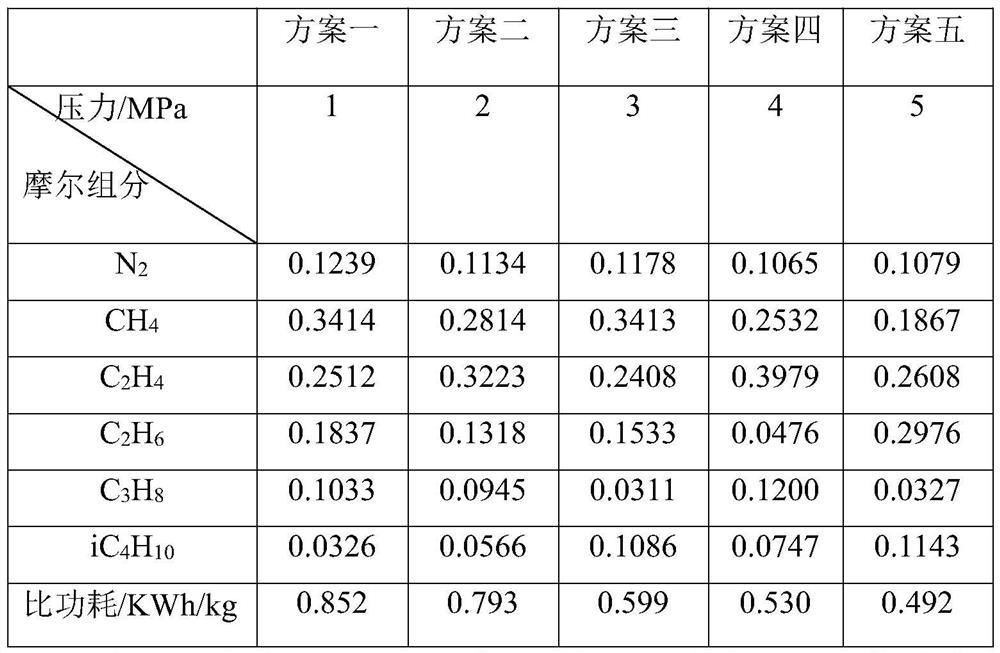

[0053] Scheme 1: When the boost pressure of BOG is 1MPa, N 2 Molarity is 12.39%, CH 4 The molar concentration is 34.14%, C 2 h 4 The molar concentration is 25.12%, C 2 h 6 Molarity is 18.37%, C 3 h 8 Molarity is 10.33%, iC 4 h 10 The molarity is 3.26%.

[0054] Scheme 2: When the boost pressure of BOG is 2MPa, N 2 Molarity is 11.34%, CH 4 The molar concentration is 28.14%, C 2 h 4 The molar concentration is 32.23%, C 2 h 6 The molar concentration is 13.18%, C3 h 8 9.45% molar concentration, iC 4 h 10 The molarity is 5.66%.

[0055] Scheme 3: When the boost pressure of BOG is 3MPa, N 2 Molarity is 11.78%, CH 4 The molar concentration is 34.13%, C 2 h 4 The molar concentration is 24.08%, C 2 h 6 The molar concentration is 15.33%, C 3 h 8 Molar concentration is 3.11%, iC 4 h 10 The molar concentration is 10.86%.

[0056] Scheme 4: When the boost pressure of BOG is 4MPa, N 2 Molarity is 10.65%, CH 4 The molar concentration is 25.32%, C 2 h 4 The mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com