Preparation method of high-light-resistance low-cost titanium dioxide

A titanium dioxide, low-cost technology, applied in the direction of chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problem of affecting the color of the product, to save production costs, improve light resistance, improve dispersion and hiding power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

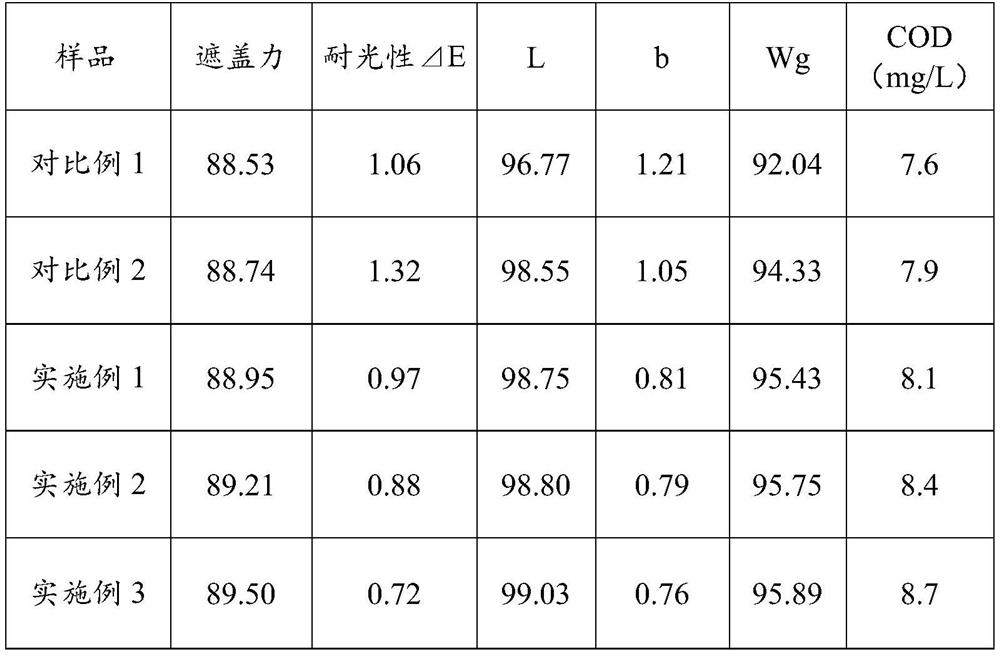

Examples

preparation example Construction

[0025] The preparation method of high light fastness and low cost titanium dioxide provided by the invention comprises the following steps:

[0026] S1. Take the titanium dioxide-based material slurry, add waste secondary titanium oxychloride, and phosphoric acid or phosphate to the slurry, and homogenize to form a titanium phosphate coating layer;

[0027] S2. Continue to add phosphoric acid or phosphate to the slurry, homogenize, then add coating agent a, homogenize, finally add magnesium salt, homogenize, form a magnesium phosphate coating layer, coating agent a is added with lemon malic acid / malate solution of acid-sodium citrate buffer pair;

[0028] S3. Adjust the pH of the slurry to 7.5-8.5, then add aluminum salt and waste paratitanium oxychloride at the same time, keep the pH of the co-current flow at 7.5-8.5, and homogenize to form an aluminum oxide coating layer.

[0029] The waste para-titanium oxychloride is obtained by spraying the tail gas produced after chlori...

Embodiment 1

[0046] The prepared sand grinding slurry is pumped into the coating tank, and the slurry concentration is adjusted to be 300g / L (in the form of TiO 2 meter), while raising the temperature to 80°C; simultaneously adding 0.6% of the purified waste by-TiOCl 2 Solution (Fe content 3ppm, HCl content 30g / L, TiO 2 content about 50g / L, V content 20ppm) and 1.0% Na 4 P 2 o 7 Solution, after 60 minutes, the pH is 2, homogenized for 30 minutes; add 2.0% H within 30 minutes 3 PO 4 (in P 2 o 5 ) solution, homogenized for 20 minutes; 0.50% malic acid solution was added within 20 minutes, wherein citric acid-sodium citrate buffer pair to maintain the pH of the slurry was added to the malic acid solution, homogenized for 20 minutes; 1.0% MgSO was added within 30 minutes 4 , maintain the pH of the slurry at 5 (according to the 0.1mol / L buffer to adjust the different additions of citric acid and sodium citrate in the solution), homogenize for 30min; adjust the pH to 8.0 with NaOH, and ad...

Embodiment 2

[0048] The prepared sand grinding slurry is pumped into the coating tank, and the slurry concentration is adjusted to be 300g / L (in the form of TiO 2 meter), while raising the temperature to 80°C; simultaneously adding 0.8% of the purified waste by-TiOCl 2 solution and 1.5% Na 4 P 2 o 7 Solution, after 60 minutes, the pH is 2.5, homogenized for 30 minutes; add 2.5% H within 30 minutes 3 PO 4 (in P 2 o 5 ) solution, homogenized for 20 minutes; 0.80% malic acid solution was added within 20 minutes, wherein the malic acid solution was added with citric acid-sodium citrate buffer pair to maintain the pH of the slurry, homogenized for 20 minutes; 1.5% MgSO was added within 30 minutes 4 , maintain the pH of the slurry at 5.5 (according to the 0.1mol / L buffer to adjust the different additions of citric acid and sodium citrate in the solution), homogenize for 30min; adjust the pH to 8.2 with NaOH, and add 2.5% NaAlO in parallel within 90min 2 and purified waste TiOCl 2 , keep ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap