Consolidation type temporary plugging agent and temporary plugging method

A temporary plugging agent and knotting technology, which is applied in chemical instruments and methods, earth-moving drilling, wellbore/well components, etc. The process is simplified, the temporary plugging effect is good, and the reservoir damage is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] This embodiment provides a consolidated temporary plugging agent that can be used for layered fracturing in low-temperature vertical wells.

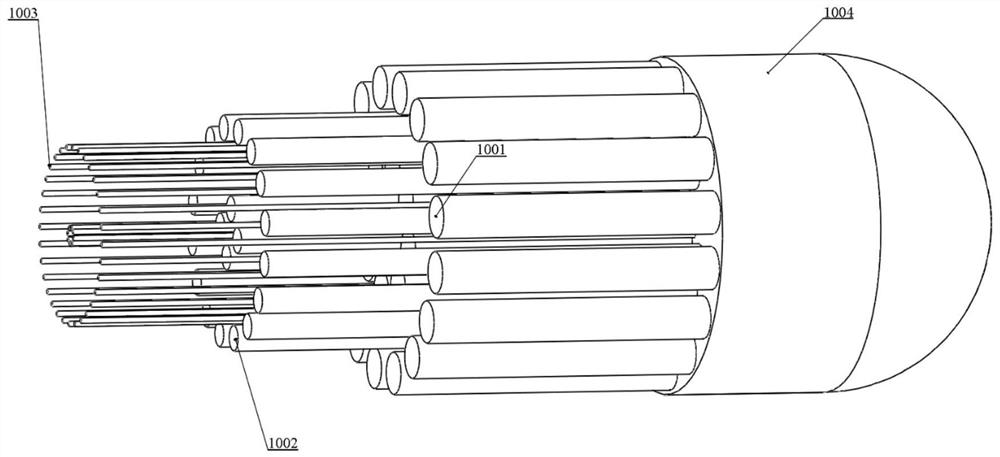

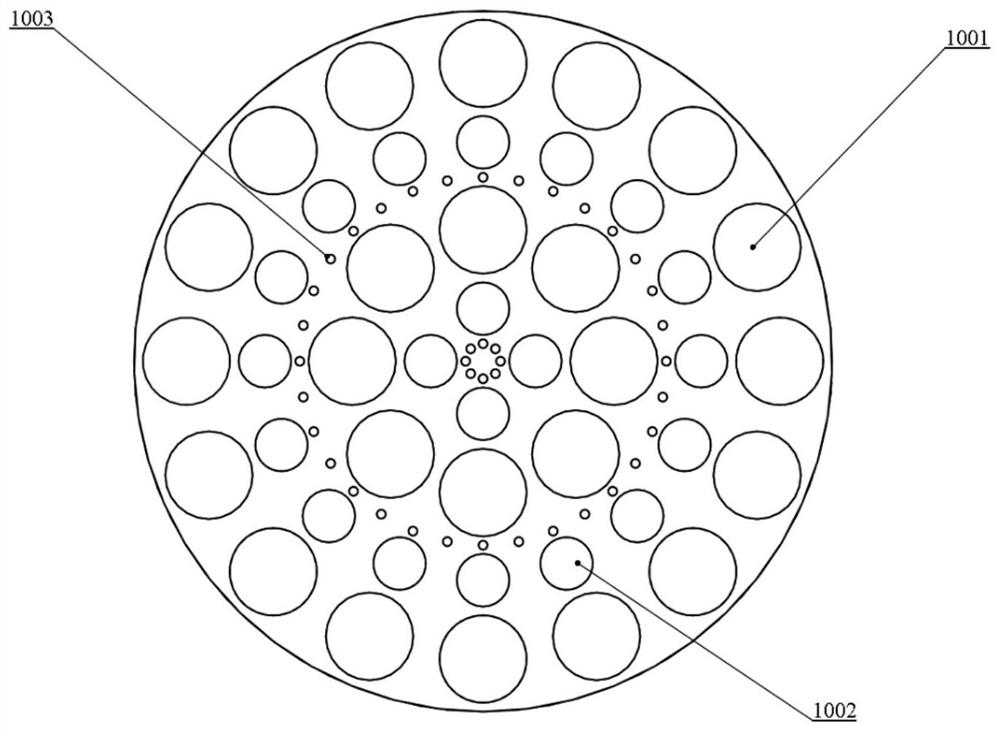

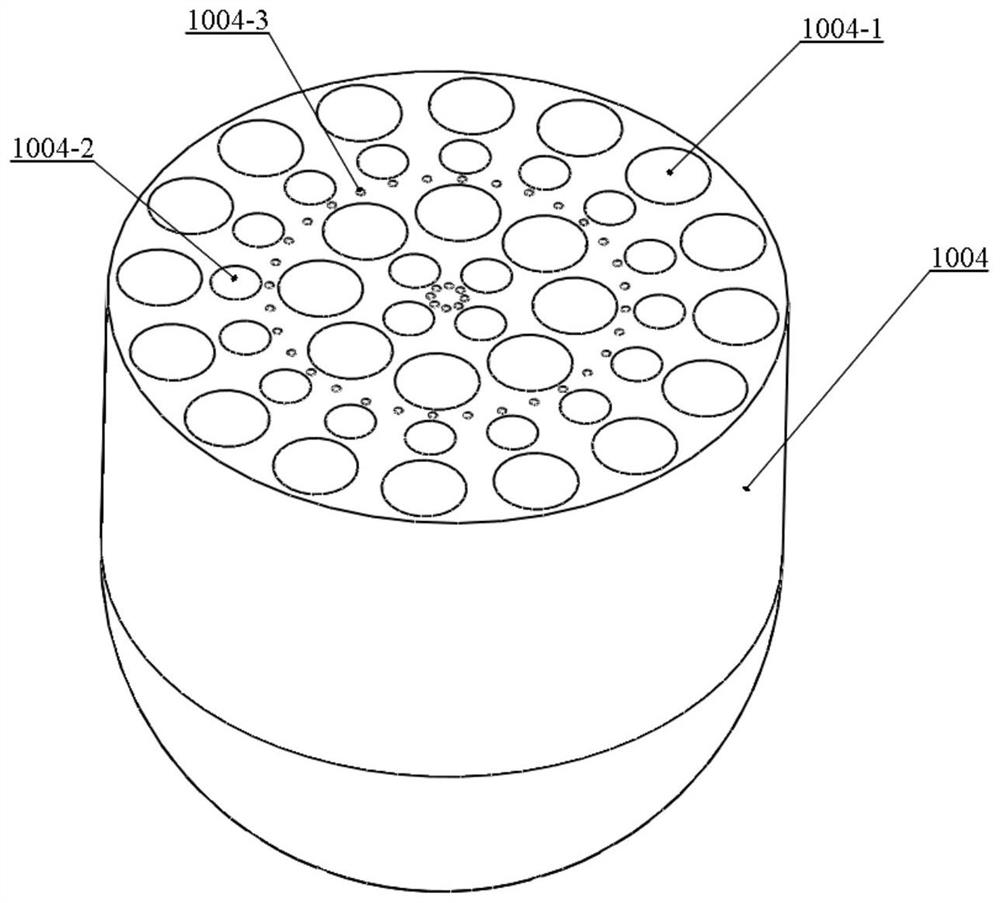

[0063] Such as Figure 1-Figure 4 As shown, the consolidated temporary plugging agent includes a thick wire 1001 , a medium wire 1002 , a thin wire 1003 , a connecting body 1004 and a shell 1005 . The connecting body 1004 includes a thick wire joint 1004-1, a medium wire joint 1004-2 and a thin wire joint 1004-3. The thick wire 1001 is connected to the connecting body 1004 through the thick wire joint 1004-1, the medium wire 1002 is connected to the connecting body 1004 through the medium wire joint 1004-2, and the thin wire 1003 is connected to the connecting body 1004 through the thin wire joint 1004-3. The present invention has no specific limitation on the distribution of thick filaments, medium filaments and thin filaments, as in this embodiment, they can be distributed in circles. The thick wire 1001 of the consolidated te...

Embodiment 2

[0072] This embodiment provides a consolidated temporary plugging agent that can be used for staged fracturing of high-temperature horizontal wells.

[0073] The consolidated temporary plugging agent includes a thick wire 1001, a medium wire 1002, a thin wire 1003, a connecting body 1004 and a shell 1005, wherein the connecting body 1004 includes a thick wire joint 1004-1, a medium wire joint 1004-2 and a thin wire joint 1004 -3. The thick wire 1001 is connected to the connecting body 1004 through the thick wire joint 1004-1, the medium wire 1002 is connected to the connecting body 1004 through the medium wire joint 1004-2, and the thin wire 1003 is connected to the connecting body 1004 through the thin wire joint 1004-3.

[0074] The thick wire 1001 of the consolidated temporary plugging agent has a diameter of 0.5 mm and a length of 30.0 mm, the medium wire 1002 has a diameter of 0.3 mm and a length of 40.0 mm, the thin wire 1003 has a diameter of 0.05 mm and a length of 50....

Embodiment 3

[0083] This embodiment provides a consolidated temporary plugging agent that can be used for temporary plugging in normal temperature vertical well workover.

[0084] The consolidated temporary plugging agent includes a thick wire 1001, a medium wire 1002, a thin wire 1003, a connecting body 1004 and a shell 1005, wherein the connecting body 1004 includes a thick wire joint 1004-1, a medium wire joint 1004-2 and a thin wire joint 1004 -3. The thick wire 1001 is connected to the connecting body 1004 through the thick wire joint 1004-1, the medium wire 1002 is connected to the connecting body 1004 through the medium wire joint 1004-2, and the thin wire 1003 is connected to the connecting body 1004 through the thin wire joint 1004-3.

[0085] The thick filament 1001 of the consolidated temporary plugging agent has a diameter of 0.8mm and a length of 18.0mm, the medium filament 1002 has a diameter of 0.4mm and a length of 24.0mm, the thin filament 1003 has a diameter of 0.1mm and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com