Novel tongue-and-groove assembly type pavement slab and maintenance and replacement method of assembly type pavement

A prefabricated, panel technology, applied in the direction of road repair, roads, roads, etc., can solve the problems of not being popularized and applied in a large area, the difficulty of repairing the road panel, taking out and putting back the difficult surface, etc., to improve the uniformity of load transmission, Improve construction efficiency and quickly replace and repair the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

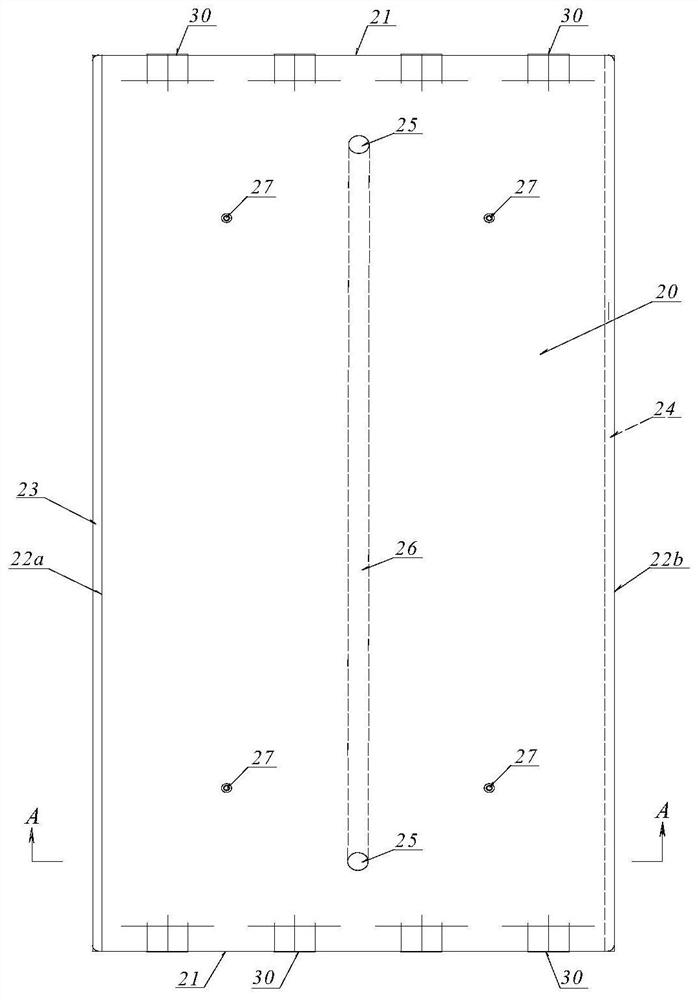

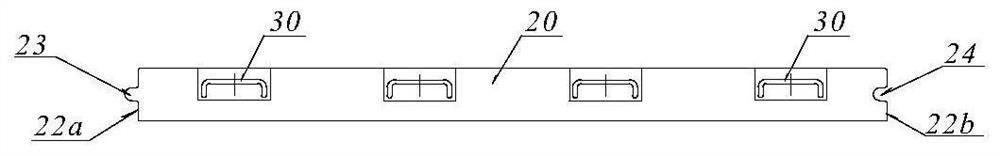

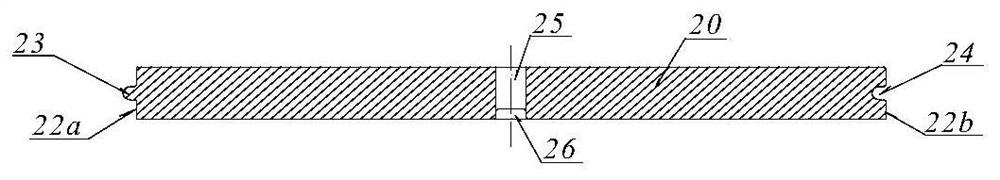

[0051] refer to figure 1 , figure 2 , Figure 4 with Figure 5, a novel tongue-and-groove assembled road panel of the present invention has a rectangular board body 20 assembled to form a road surface. Dowel bars 30 are buried at intervals along the width direction at the two lengthwise side walls 21 of the rectangular plate body 20, and the dowel bars 30 of two adjacent rectangular plate bodies 20 in the length direction are correspondingly welded and connected to realize the rectangular plate body 20 in the road. Assembled horizontally. refer to figure 1 , figure 2 with Figure 14a The left side wall 22a in the width direction and the right side wall 22b in the width direction of the rectangular plate body 20 are respectively provided with corresponding connecting tenons 23 and connecting grooves 24, and the connecting tenons 23 are snapped i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com