All-aluminum alloy building modular structure

An aluminum alloy, modular technology, applied in the direction of building components, building structure, construction, etc., can solve the problems of many installation procedures, high production cost, complex assembly, etc., to achieve strong corrosion resistance, strong machinability, assembly high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

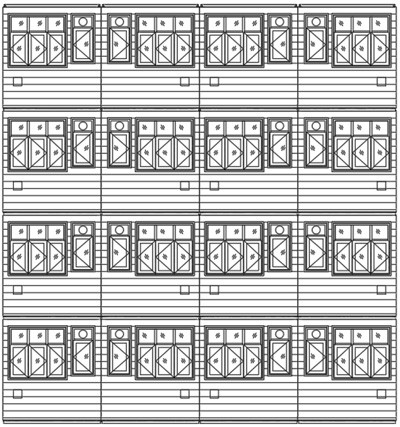

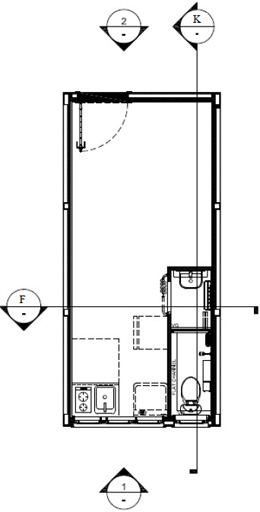

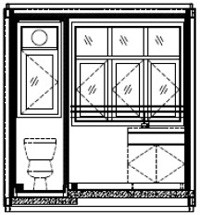

[0055]see Figure 1 to Figure 9 , The present invention provides a modular structure of an all-aluminum alloy building. The all-aluminum alloy building is composed of several modules, and each module constitutes a unit. Each module is composed of a module frame bottom 1, a module frame top 2 and frame connecting members. The interior of each unit is decorated and equipped with home supporting facilities.

[0056] The frame connecting members of each module are mainly composed of columns 4 , module bottom beams 41 , module top beams 43 and diagonal braces 10 . The diagonal braces 10 are intersectingly connected between the module bottom beam 41 and the module top beam 43, and the interconnection between the module bottom beam 41 and the module top beam 43 is designed as a fitting form, and the top beam of the lower module is inserted into the bottom ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap