Remote DPF regeneration control method for vehicle engine

An engine controller and regenerative control technology, applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems affecting the normal use of vehicles and user experience, high service costs, low work efficiency, etc., to facilitate real-time online Effects of recording and playback, restoration of filtering performance, and reduction of service costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

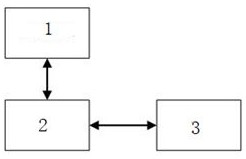

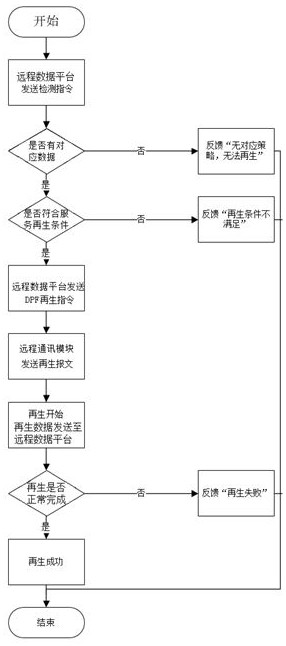

[0074] Please see attached figure 1 And attached figure 2 , Step 1: When the vehicle has a DPF regeneration demand, the service personnel can click the "Service Regeneration" button on the man-machine interface of the remote data platform 3 to start the remote DPF regeneration control process, and the remote data platform 3 sends a detection to the remote communication module 2 instruction.

[0075] Step 2: After receiving the detection instruction, the remote communication module 2 reads the parameter information from the engine controller 1 through the CAN harness, and sends the parameter information to the remote data platform 3 .

[0076] The parameter information includes vehicle ECU data version information 6K23006A48 and related parameter data. The related parameter data includes engine speed of 800rpm, engine coolant temperature of 75°C, PTO switch status of 0, DOC upstream exhaust temperature of 174°C and total The particle mass is 38.4g, which is used to judge whe...

Embodiment 2

[0081] Please see attached figure 1 And attached figure 2 , Step 1: When the vehicle has a DPF regeneration demand, the service personnel can click the "Service Regeneration" button on the man-machine interface of the remote data platform 3 to start the remote DPF regeneration control process, and the remote data platform 3 sends a detection to the remote communication module 2 instruction.

[0082] Step 2: After receiving the detection instruction, the remote communication module 2 reads the parameter information from the engine controller 1 through the CAN harness, and sends the parameter information to the remote data platform 3 .

[0083] The parameter information includes the vehicle ECU data version information 6K25006A48 and related parameter data. The related parameter data includes the engine speed at 800rpm, the engine coolant temperature at 80°C, the PTO switch state at 0OC, the upstream exhaust temperature at 170°C and the total particulate matter mass It is 46g...

Embodiment 3

[0092] Please see attached figure 1 And attached figure 2 , Step 1: When the vehicle has a DPF regeneration demand, the service personnel can click the "Service Regeneration" button on the man-machine interface of the remote data platform 3 to start the remote DPF regeneration control process, and the remote data platform 3 sends a detection to the remote communication module 2 instruction.

[0093] Step 2: After receiving the detection instruction, the remote communication module 2 reads the parameter information from the engine controller 1 through the CAN harness, and sends the parameter information to the remote data platform 3 .

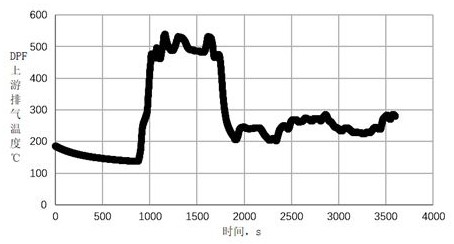

[0094] The parameter information includes vehicle ECU data version information 6K25006A48 and related parameter data. The related parameter data includes engine speed of 797rpm, engine coolant temperature of 71°C, PTO switch status of 0, DOC upstream exhaust temperature of 320°C and total The mass of particulate matter is 18g, which is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com