Method for checking precision of oil consumption measuring equipment

A technology for measuring equipment and calibration methods, applied in the direction of measuring devices, testing/calibrating devices, testing/calibrating volume flow, etc., can solve the problems of cumbersome cycle, low efficiency, complicated operation, etc., and achieve convenient operation, few functional parts, The effect of ensuring the accuracy of the calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the drawings and embodiments, but the protection scope of the present invention should not be limited accordingly.

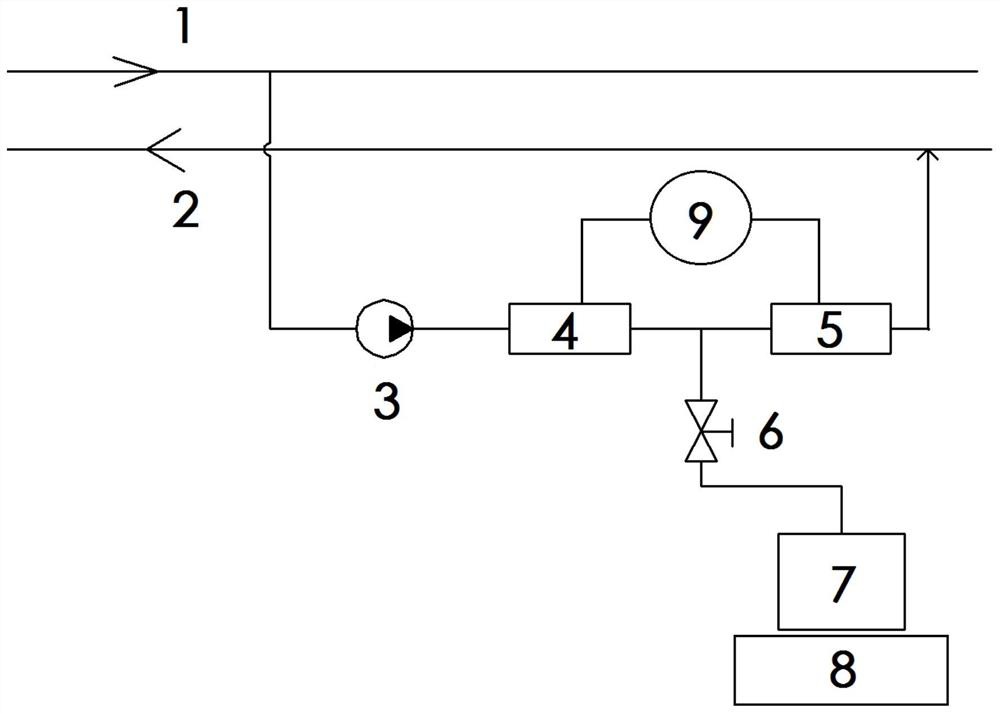

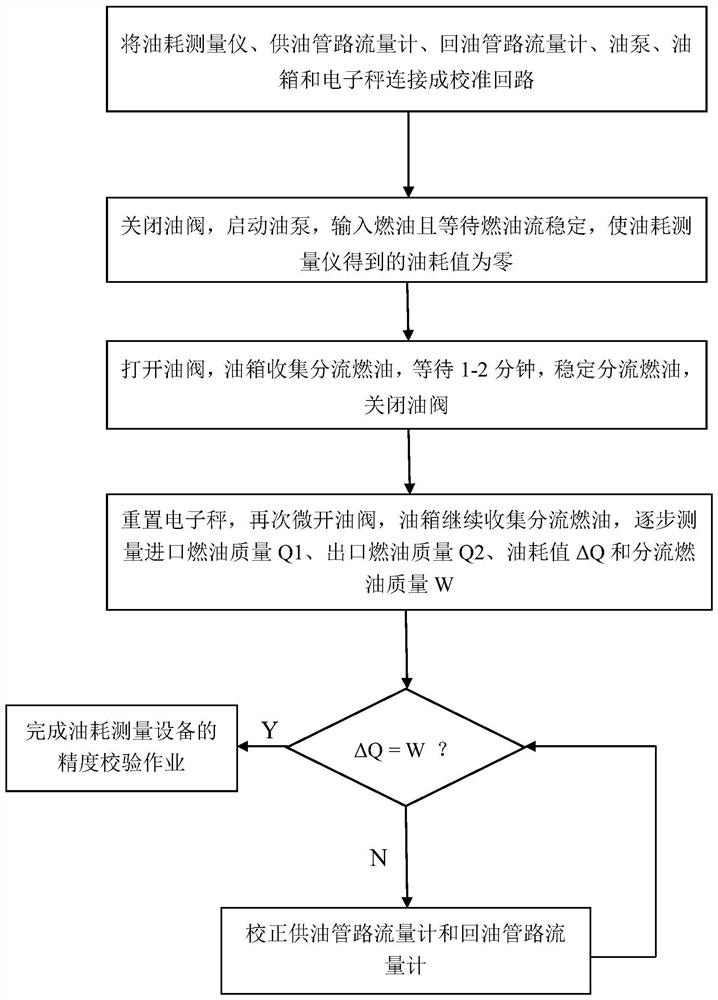

[0029] The invention is used to calibrate the accuracy of the fuel consumption measuring equipment used in the test run of the main engine. The fuel consumption measuring equipment includes a fuel supply pipeline flowmeter, a fuel return pipeline flowmeter and a fuel consumption measuring instrument. The fuel supply pipeline flowmeter is connected to On the main fuel input pipe, the oil return pipeline flowmeter is connected to the fuel main output pipe, and the fuel consumption measuring instrument is respectively connected to the fuel supply pipeline flowmeter and the fuel return pipeline flowmeter.

[0030] see figure 1 , the present invention connects the oil supply pipeline flowmeter 4 and the oil return pipeline flowmeter 5 connected in series into the calibration lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com