Asphalt mixture three-dimensional void connectivity characterization and evaluation method

A technology of asphalt mixture and three-dimensional voids, which is applied in the analysis of materials, permeability/surface area analysis, suspension and porous material analysis, etc., and can solve the problems that do not consider the randomness and variability of void structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

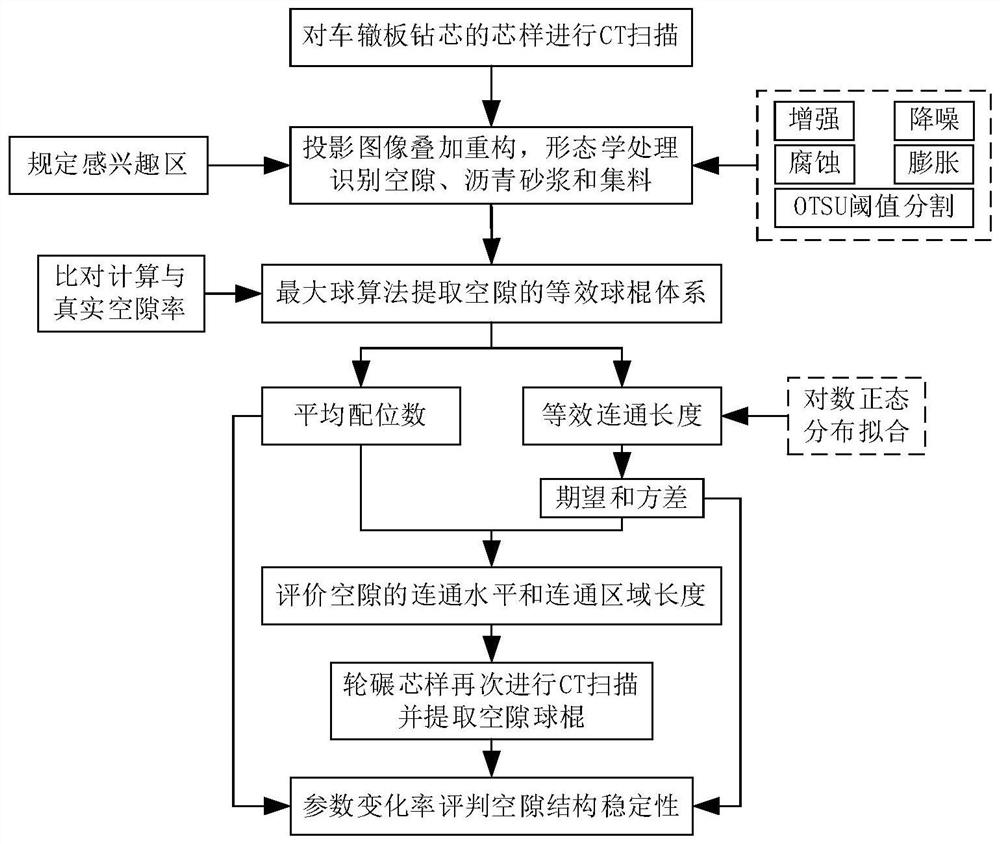

[0050] Such as figure 1 As shown, it is a characterization and evaluation method for the three-dimensional void connectivity of asphalt mixture proposed by the present invention, and the specific steps are as follows:

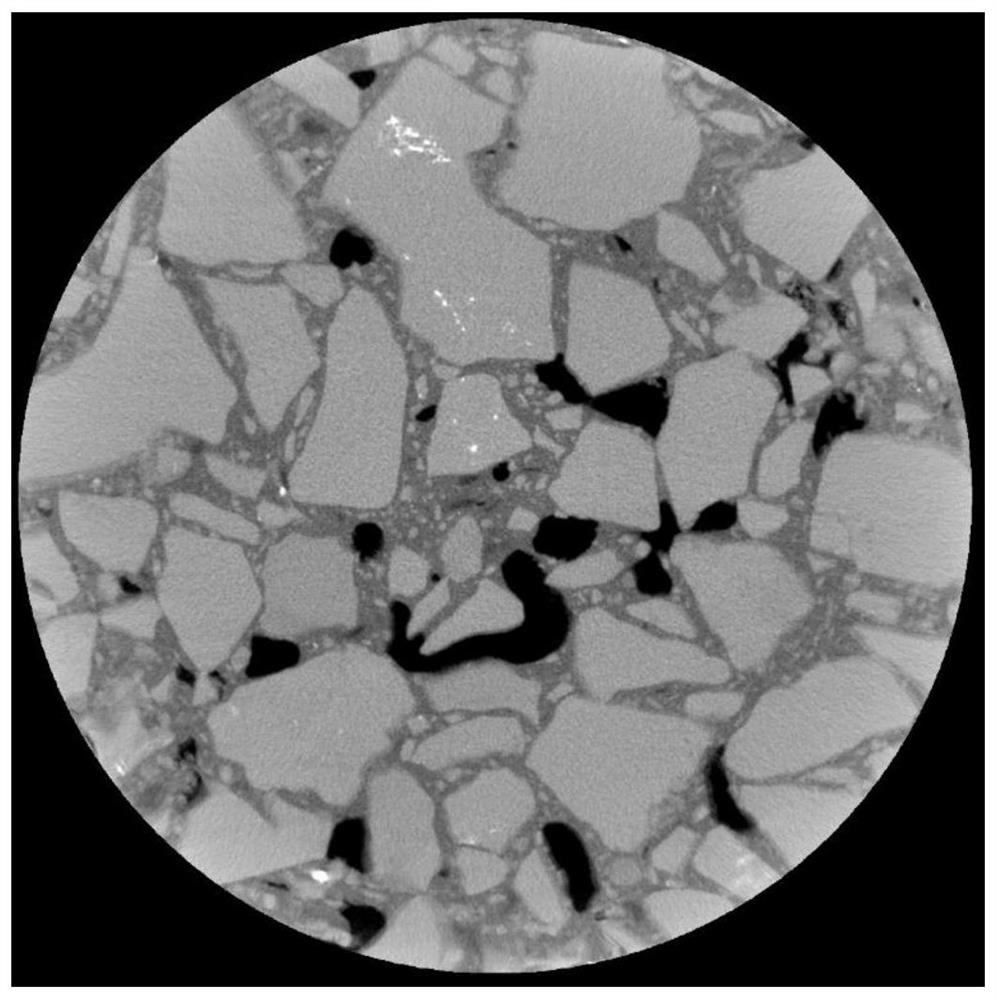

[0051] (1) Prepare the asphalt mixture rutting slab specimen and cut the drill core, and perform CT tomographic scanning on the core sample;

[0052] 1) Carry out the Marshall compaction test to determine the optimum asphalt ratio of 5 kinds of asphalt mixtures, and use the wheel rolling method to form the plate-shaped samples of the corresponding mixtures. The rutting plate samples are 300mm long, 300mm wide, and 50mm high;

[0053] 2) Cut both sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com