IGBT junction-to-case thermal resistance measuring method based on large current saturation voltage drop

A measurement method and high-current technology, applied in the measurement of current/voltage, measurement device, measurement of electrical variables, etc., can solve the problems of high cost, large error, complex temperature measurement system structure, etc., to achieve a wide range of applications, protect integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

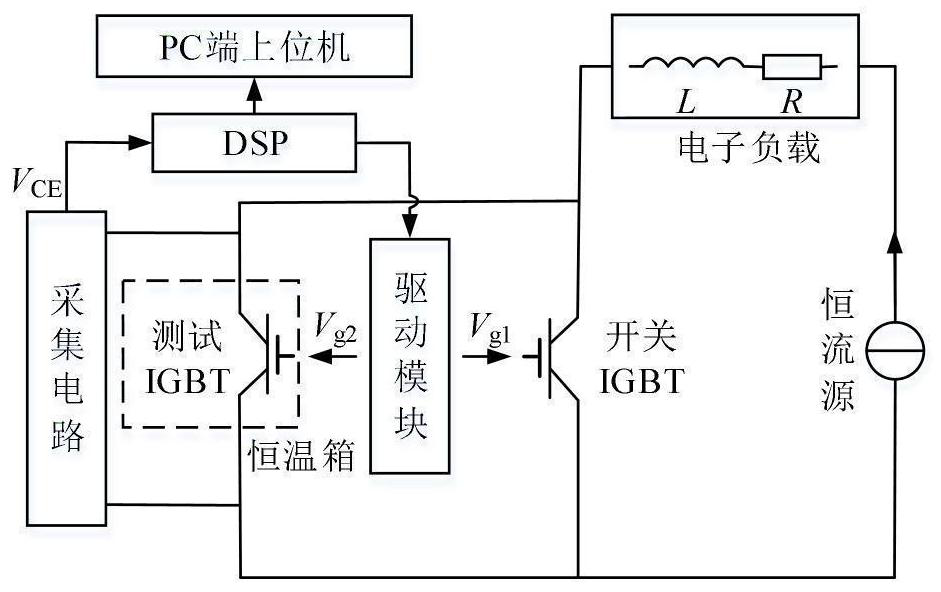

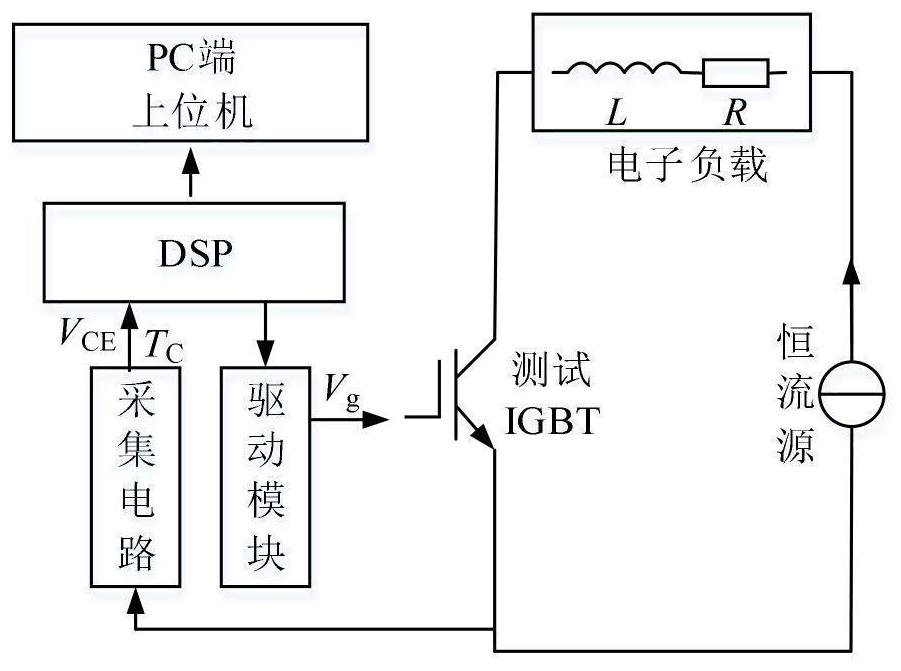

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

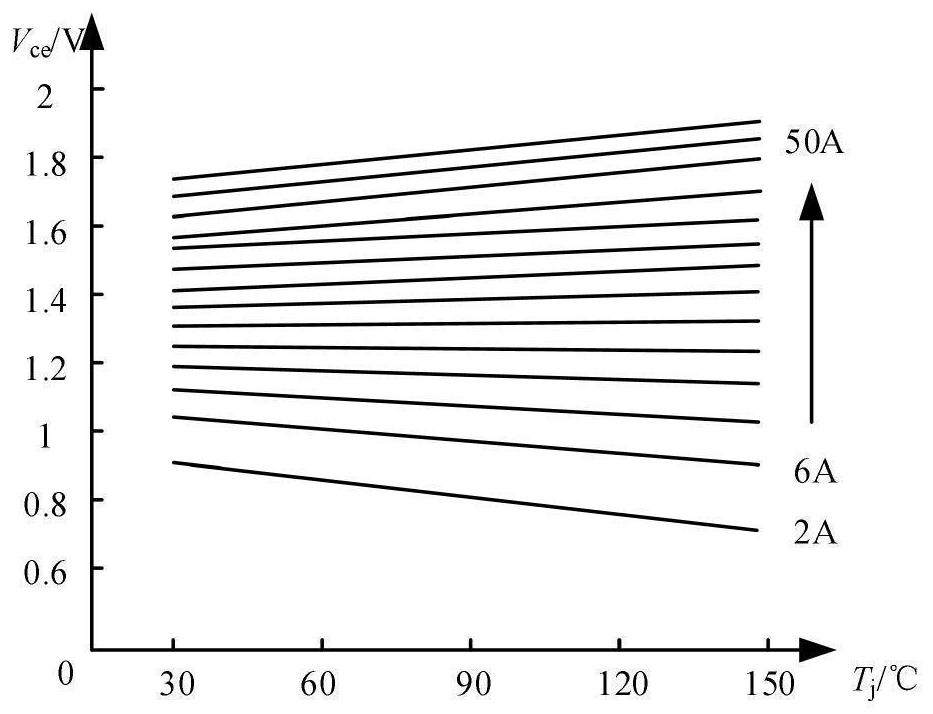

[0039] The current conduction loop of the IGBT module is composed of four parts: the chip, the bonding wire, the chip solder layer and the copper layer on the DBC. The voltage drop at the end of the IGBT module is mainly composed of two parts, one part is the voltage drop V on the chip chip , the other part is the parasitic resistance voltage drop R of the IGBT module stray , while V chip In addition to being affected by the collector-emitter current I CE In addition to the impact, it is also affected by the chip junction temperature T j Impact. The conduction voltage drop expression of the IGBT module is shown in formula (1).

[0040] V CE =V chip +V stray =[V 0 -k 1 (T j -T j0 )]+[R 0 +R stray +k 2 (T j -T j0 )]×I CE (1)

[0041] V 0 is the internal PN junction voltage drop when the IGBT module is turned on, R ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com