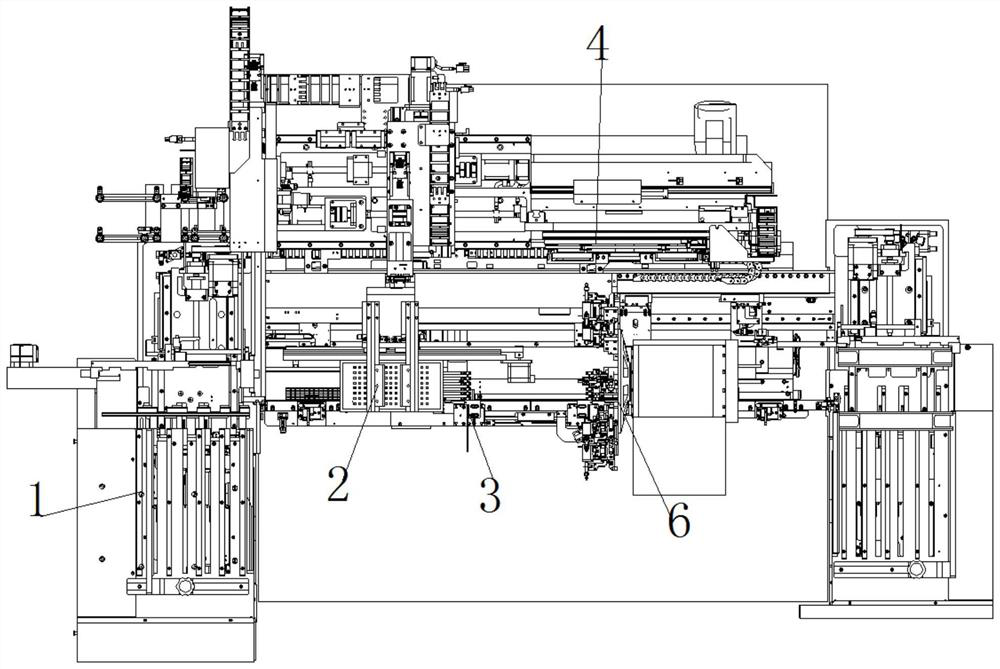

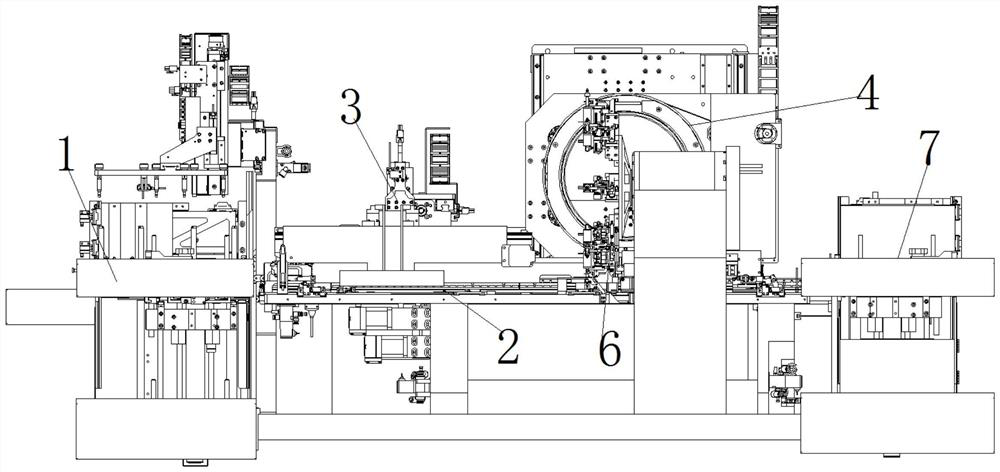

High-speed and high-precision die bonder and use method thereof

A high-precision, crystal-bonding machine technology, applied in the direction of conveyor objects, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of swing arm length accuracy, variation, low efficiency of single dispensing of syringe dispensing valves, etc. , to achieve the effect of improving the precision of solidification, improving efficiency and stability, and shortening the distance of horizontal movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

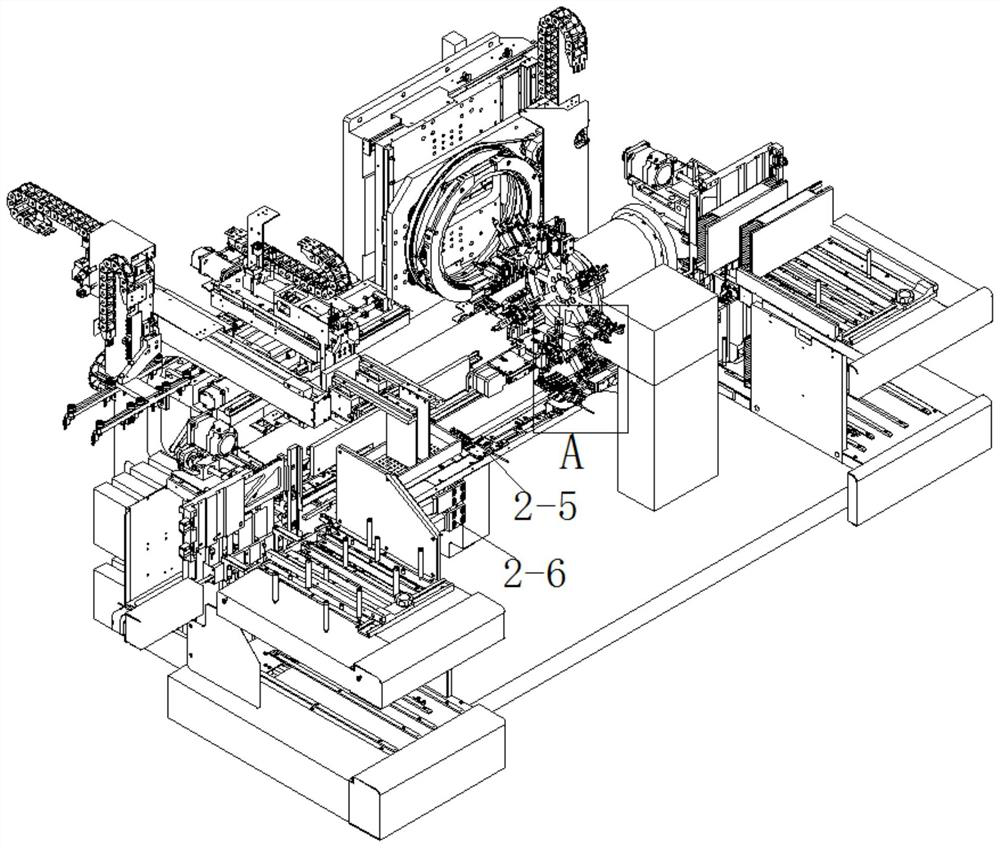

Embodiment

[0051] Embodiment: In this embodiment, eight force control motors 6-5 are arranged at circumferential intervals of the welding head swing arm 6-2. During operation, the crystal frame base 4-1 is first driven to rotate by the wafer rotating motor 4-4 , to correct the angle of the wafer, select the loading mode of the dual-mode loading device 1, when selecting the stacked substrate loading, pull out the loading rail 1-4 from the pushing box mechanism 1-2, and suck the material Mechanism 1-1 moves to the top of stacking table 1-3 to pick up the substrate, and transports the substrate to the feeding track 1-4, and the feeding track 1-4 transports the substrate to the inside of the track. 1-4 is retracted to the bottom of the pusher box mechanism 1-2, the pusher box mechanism 1-2 pushes the material box to be transported to the lifting platform 1-7, and the pusher mechanism 1-6 pushes the substrate from the material box to the inside of the track, Afterwards, the lifting platform 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com