Heating control system and heating control method for separate control of cast polycrystalline silicon top

A technology of heating control and polysilicon, which is applied in the growth of polycrystalline materials, chemical instruments and methods, and crystal growth, etc. It can solve the problems of uneven crystal melting interface, affecting the quality of crystal forming, long cycle of ingot casting technology, etc., and achieve the height of seed crystal The effect of reducing and avoiding heat loss and shortening the overall ingot casting cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

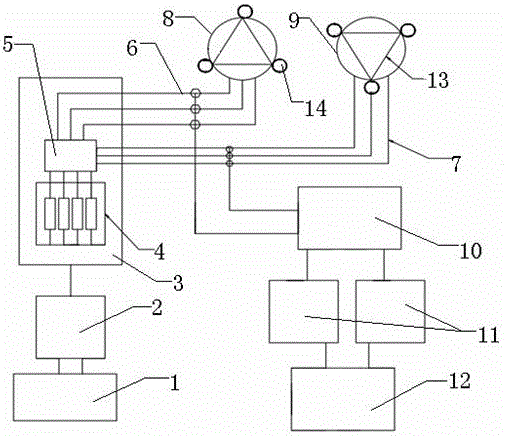

[0017] The system includes a man-machine interface 1 and a power distribution cabinet 10, the man-machine interface 1 is connected to the industrial computer 2, and the industrial computer 2 is connected to the control cabinet 3, such as figure 1 As shown, the control cabinet 3 is provided with a control module 4, and the control module 4 is connected to the thyristor 5, and one path of the thyristor 5 is connected to the top control thyristor 8 through the top signal line 6, and the other path of the thyristor 5 is The side control thyristor 9 is connected through the side signal line 7, and the side signal line 7 and the top signal line 6 are both connected to the power distribution cabinet 10, and the power distribution cabinet 10 is connected to the external through two parallel transformers 11. The power supply 12 , the top control thyristor 8 and the side control thyristor 9 all include three heating electrodes 14 connected via water cables 13 .

[0018] The industrial c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com