Circumferential grinding head, multi-screw extrusion kneading machine, and pulping method

A circumferential grinding head and multi-screw technology, which is applied in pulp beating/refining methods, textiles and papermaking, fiber raw material processing, etc., can solve the problems of complex equipment, large power consumption, unfavorable energy saving, etc., to reduce content, The effect of increasing the degree of buckle release and reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

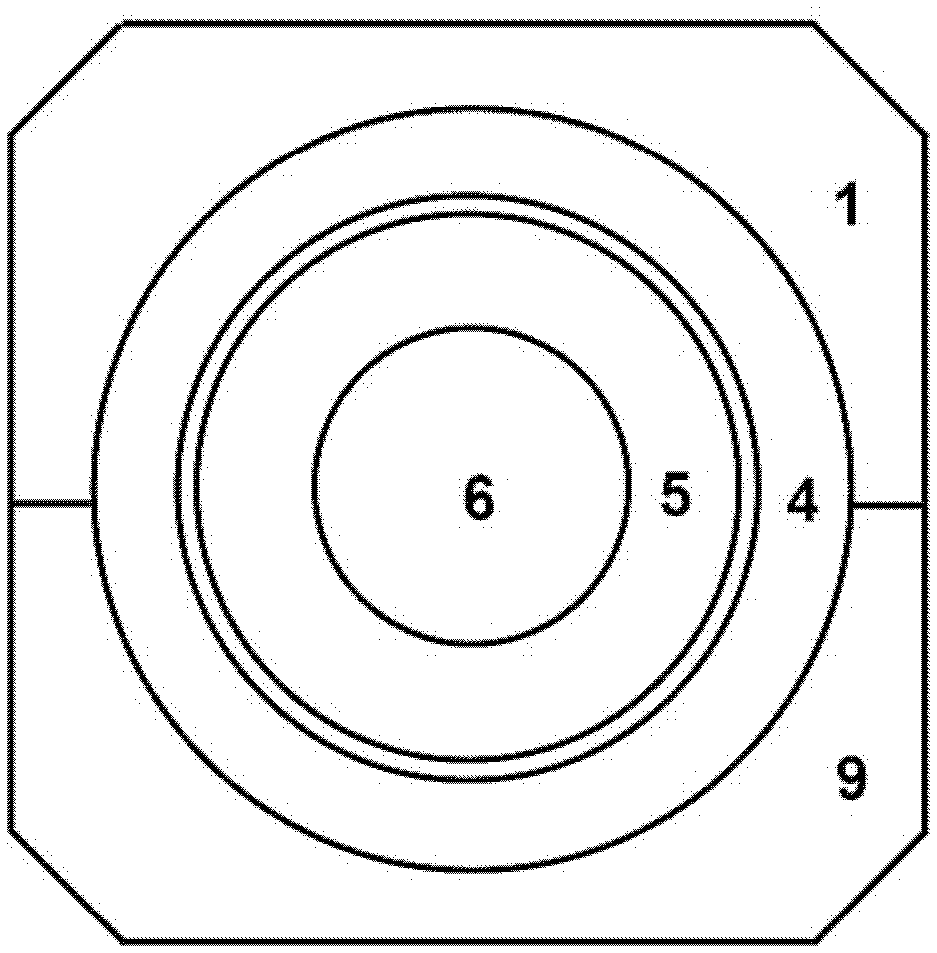

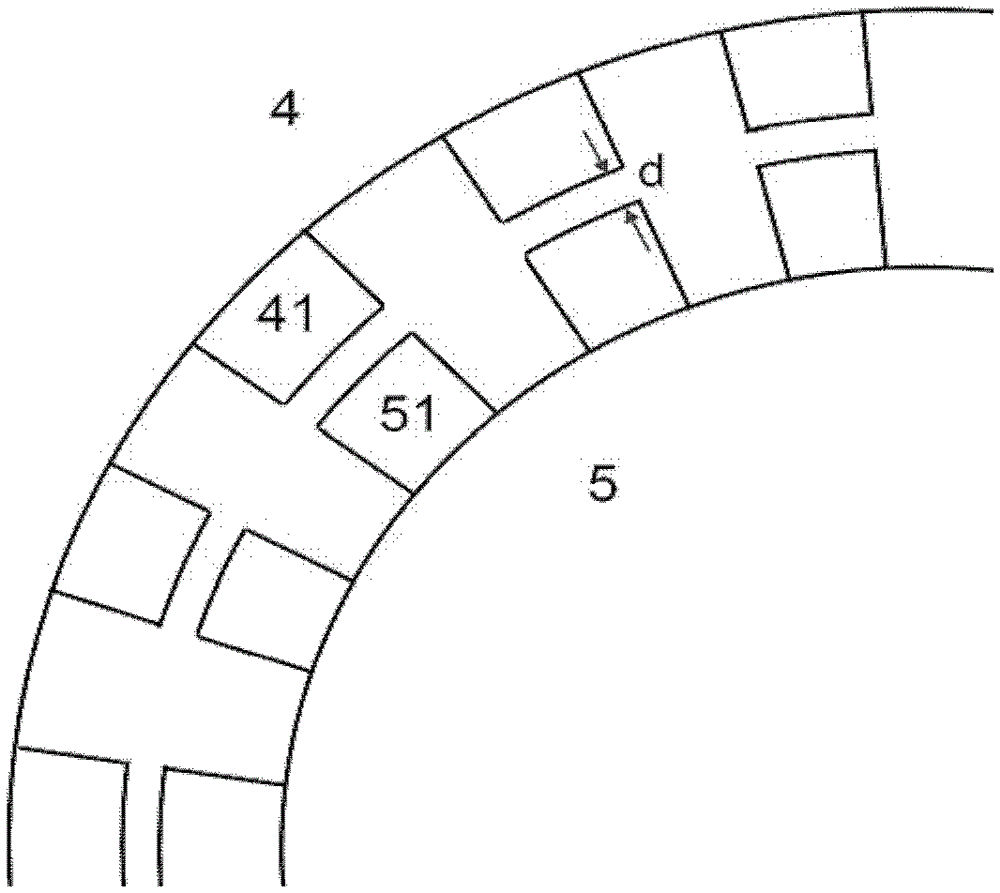

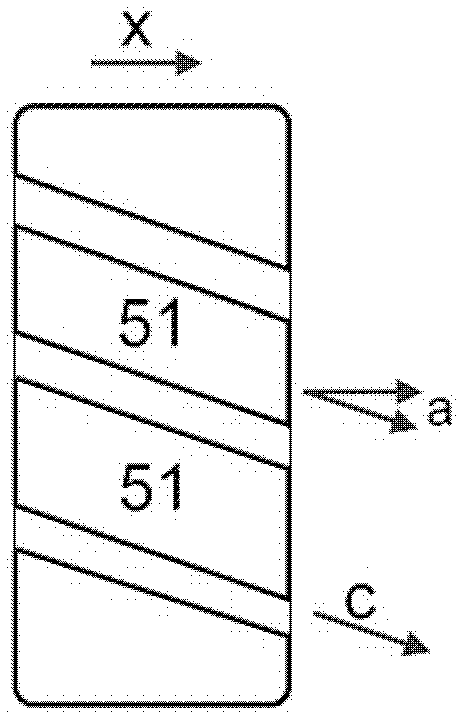

[0048] Figure 1a to Figure 1d It is a specific embodiment of the circumferential grinding head of the present invention. A circumferential grinding head, such as Figure 1a Shown, comprise mandrel 6, lining tile 4, machine barrel (can comprise upper machine barrel 1 and lower machine barrel 9 as shown in the figure), and be fixed on described mandrel 6 coaxial with mandrel 6 and follow the core Shaft 6 rotates movable grinding head 5 . The axial direction x of the mandrel 6 is therefore also the axial direction x of the movable grinding head 5 . The lining tile 4 is fixed on the barrel. Lining tile 4 and machine barrel can be split structure, it is convenient to replace it when lining tile is damaged, certainly also can be integral structure. As a specific implementation, Figure 2a The specific way of fixing the lining tile 4 to the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com