Composite connection method for large-size round-to-square 3D printer box

A 3D printer and composite connection technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as no mature methods, achieve the effect of improving welding efficiency and reducing welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

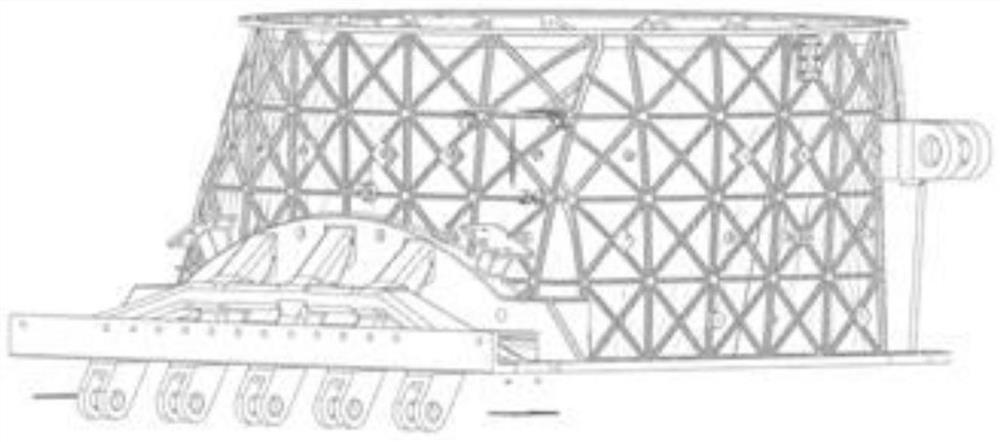

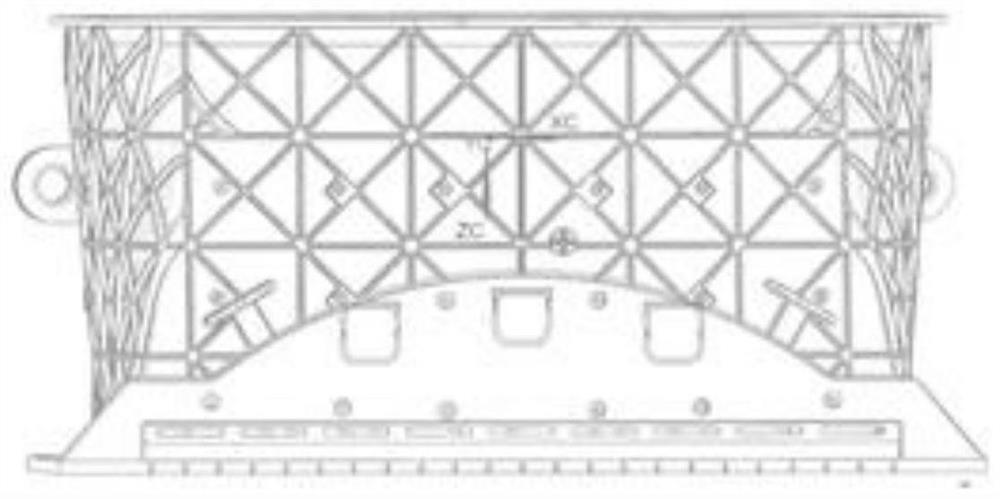

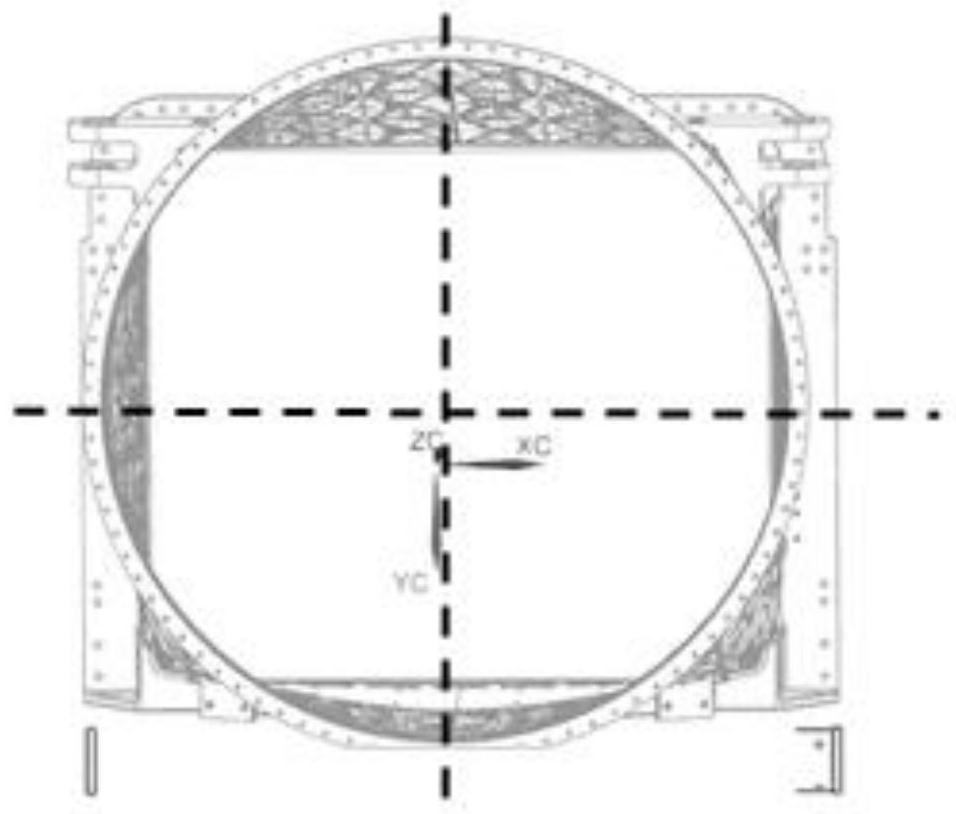

[0052] The material of an aero-engine round-to-square casing is GH4169, and the blank is a powder-coated 3D printing fan-shaped section, and its outer dimension is relatively large (1140mm). The specific process flow is: removing the external ribs at the longitudinal electron beam welds—electron beam welding longitudinal welds—laser cladding to repair the ribs—composite connection of the fifth section of the circular to square receiver—X-ray inspection— - Fluorescent detection.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com