Reconstructed well wall of closed or abandoned mine shaft and construction technology of reconstructed well wall

A technology for shaft wall and mine, which is applied in the field of shaft wall reconstruction and its construction technology, can solve the problems of difficult to meet the wellbore development and utilization, shaft wall cracking, low strength, etc., to ensure stability, low engineering cost, and short construction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

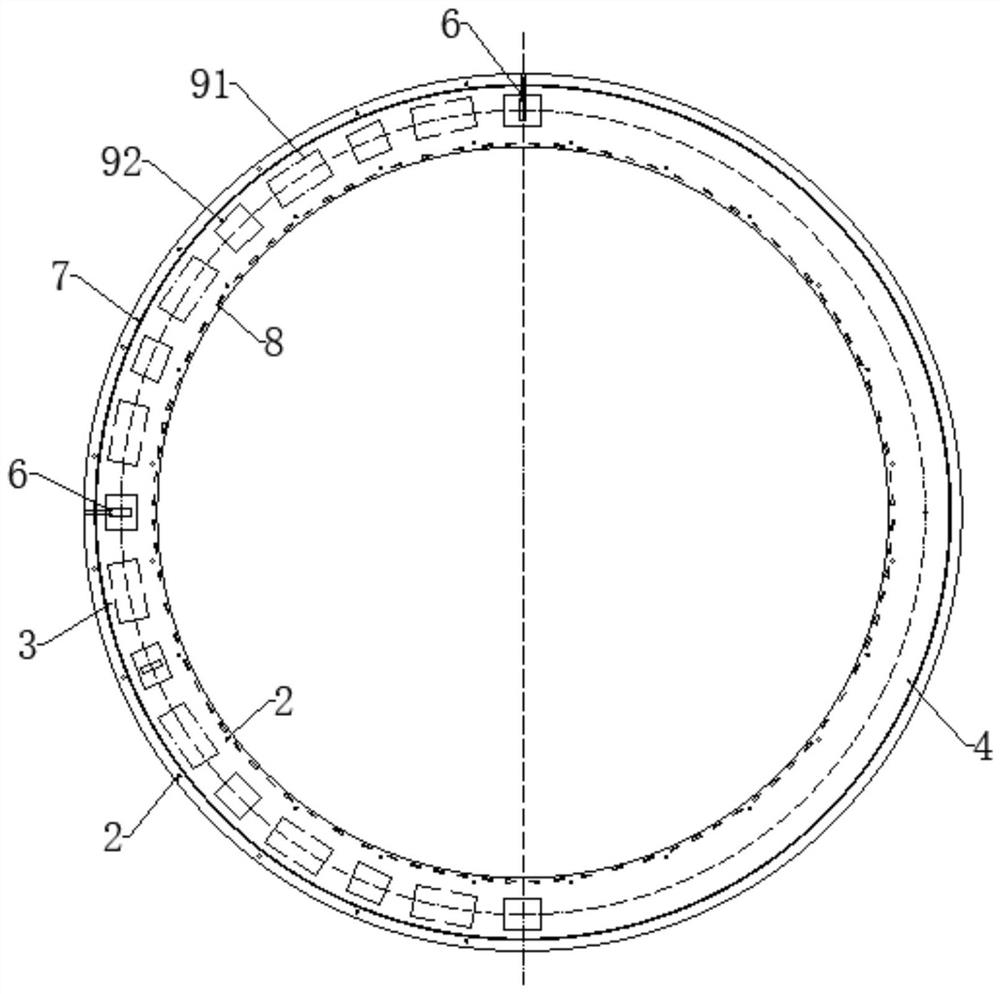

[0057] A rebuilt shaft wall for a closed or abandoned mine shaft, a shaft wall body 30 and a shaft wall bottom 10; the upper part of the shaft wall bottom 10 is a straight shaft wall section, the lower part is a hollow hemispherical shaft wall bottom, and the outer part of the straight shaft wall section diameter is equal to the ball diameter at the bottom of the hollow hemispherical well wall; the well wall body 30 is straight, and the outer diameter of the well wall body 30 is equal to the outer diameter of the straight well wall section; the bottom of the well wall body 30 is the same as the straight well wall section The top is fixedly connected and fluidly connected.

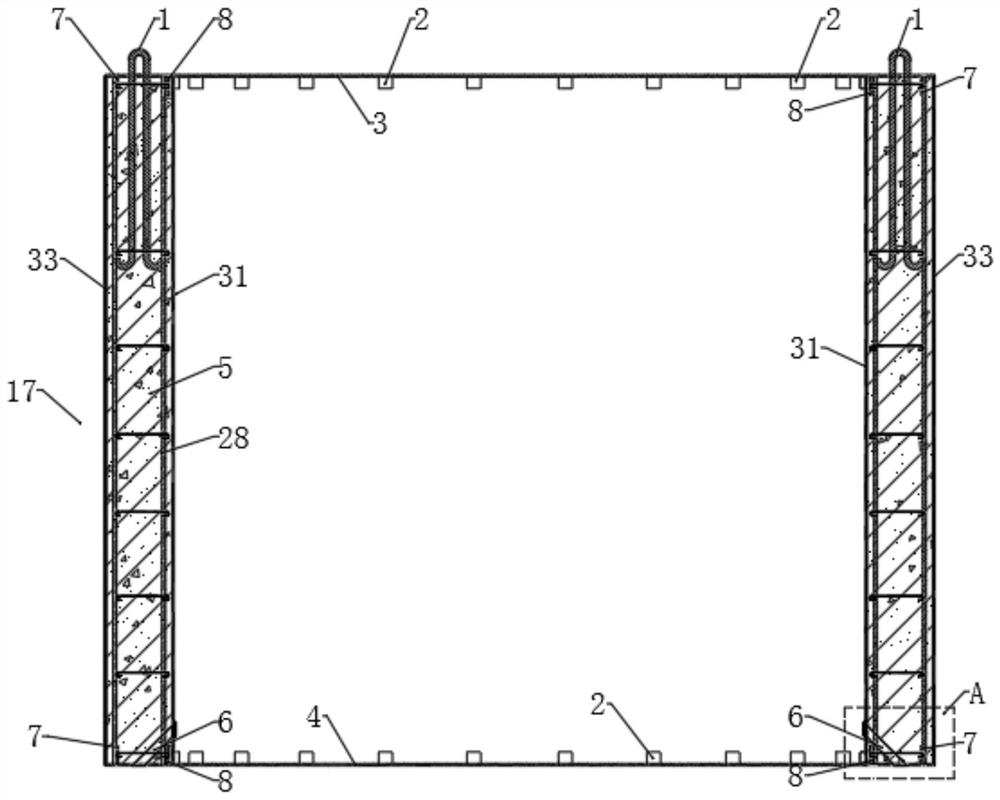

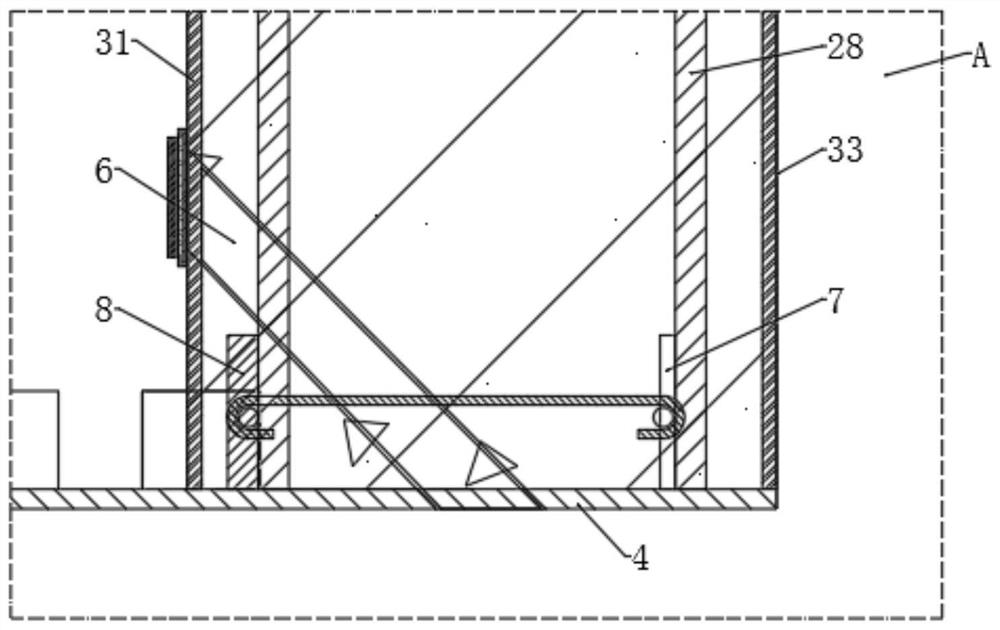

[0058] Well wall body 30 comprises 9 well wall sections 17, such as figure 1 As shown, the shaft wall joint 17 includes the shaft wall concrete 5, the shaft wall inner steel plate 31, the shaft wall outer steel plate 33, the shaft wall joint steel bar 28, the shaft wall joint upper flange 3 and the shaft wa...

Embodiment 2

[0070] Such as Figure 7 and Figure 8 Shown, a closed or abandoned mine shaft wall rebuilding construction process, including the following steps:

[0071] (1) Remove the equipment installed in the closed or abandoned mine shaft shaft, and install a lifting system at the closed or abandoned mine shaft shaft; the lifting system is a gantry crane, and the present embodiment adopts a gantry crane;

[0072](2) According to the structural requirements of the closed or abandoned mine shaft shaft, the rebuilt shaft wall 18 of the closed or abandoned mine shaft shaft as described in embodiment 1 is prefabricated on the ground; in this embodiment, the shaft wall section 17 and the shaft wall bottom 10 are The ground is prefabricated in advance, and the prefabricated shaft wall section 17 and shaft wall bottom 10 can adapt to the lifting capacity of the gantry crane;

[0073] (3) Concrete is used to block the bottom roadway of the closed or abandoned mine shaft; the plugging between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com