Calibration method of underground bit pressure and torque measuring nipple

A technology for measuring pup joints and calibration methods, which is applied in the calibration/testing of force/torque/power measuring instruments, measuring devices, instruments, etc., and can solve problems such as heavy workload of weights, affecting calibration accuracy, and low calibration efficiency. Achieve the effects of improving efficiency, improving calibration accuracy, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

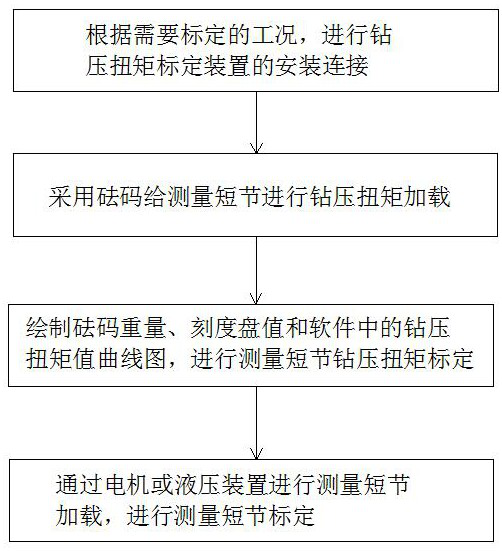

[0076] see Figure 1-Figure 4 , a method for calibrating a downhole weight-on-bit torque measuring sub, comprising the following steps:

[0077] a. According to the working conditions that need to be calibrated, install and connect the drilling pressure torque calibration device;

[0078] b. Use weights to load the measuring sub-joint 5 with the drilling pressure torque;

[0079] c. Draw weight weight, dial 18 value and the weight-on-bit torque curve in the software to calibrate the weight-on-bit torque of the measuring sub-section 5;

[0080] d. Load the measuring sub-joint 5 through the motor 24 or the hydraulic device, and perform the calibration of the measuring sub-joint 5 .

[0081] This embodiment is the most basic implementation. Not only can the measuring sub-joint 5 be directly calibrated by the weight, but also the weight on the bit torque calibration device can be calibrated first, and then the measuring sub-joint 5 can be calibrated by the bit pressure torque ca...

Embodiment 2

[0083] see Figure 1-Figure 4 , a method for calibrating a downhole weight-on-bit torque measuring sub, comprising the following steps:

[0084] a. According to the working conditions that need to be calibrated, install and connect the drilling pressure torque calibration device;

[0085] b. Use weights to load the measuring sub-joint 5 with the drilling pressure torque;

[0086] c. Draw weight weight, dial 18 value and the weight-on-bit torque curve in the software to calibrate the weight-on-bit torque of the measuring sub-section 5;

[0087] d. Load the measuring sub-joint 5 through the motor 24 or the hydraulic device, and perform the calibration of the measuring sub-joint 5 .

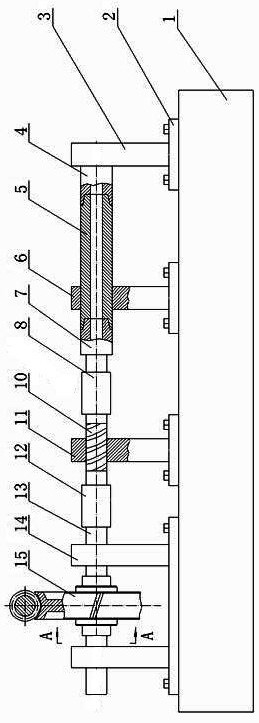

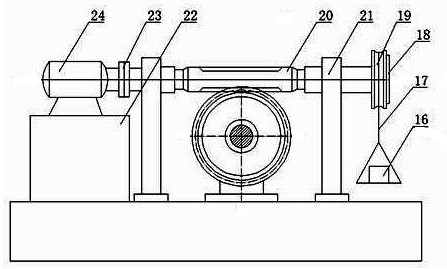

[0088] In the step a, the drilling weight torque calibration device includes a base 1, and the base 1 is fixedly connected with a short joint fixed support 3, a short joint righting support 6, a screw support 11, a worm gear support 14, and a worm support 21 And the motor support 22, the short jo...

Embodiment 3

[0092] see Figure 1-Figure 4 , a method for calibrating a downhole weight-on-bit torque measuring sub, comprising the following steps:

[0093] a. According to the working conditions that need to be calibrated, install and connect the drilling pressure torque calibration device;

[0094]b. Use weights to load the measuring sub-joint 5 with the drilling pressure torque;

[0095] c. Draw weight weight, dial 18 value and the weight-on-bit torque curve in the software to calibrate the weight-on-bit torque of the measuring sub-section 5;

[0096] d. Load the measuring sub-joint 5 through the motor 24 or the hydraulic device, and perform the calibration of the measuring sub-joint 5 .

[0097] In the step a, the drilling weight torque calibration device includes a base 1, and the base 1 is fixedly connected with a short joint fixed support 3, a short joint righting support 6, a screw support 11, a worm gear support 14, and a worm support 21 And the motor support 22, the short joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com