A valve locking mechanism and its switchgear

A technology of locking mechanism and valve, which is applied in the direction of pull-out switchgear, switchgear, switchgear components, etc., can solve the problems of shaking and bumping the valve, the moving contact of the handcart bumping into the valve, and the injury of the operator, etc., to achieve Reduce the requirements for the movement accuracy of the handcart, overcome the easy jamming, and smooth up and down movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

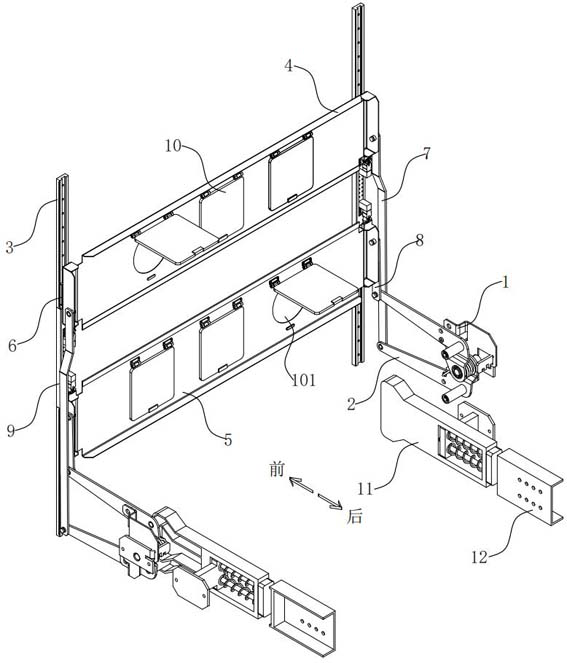

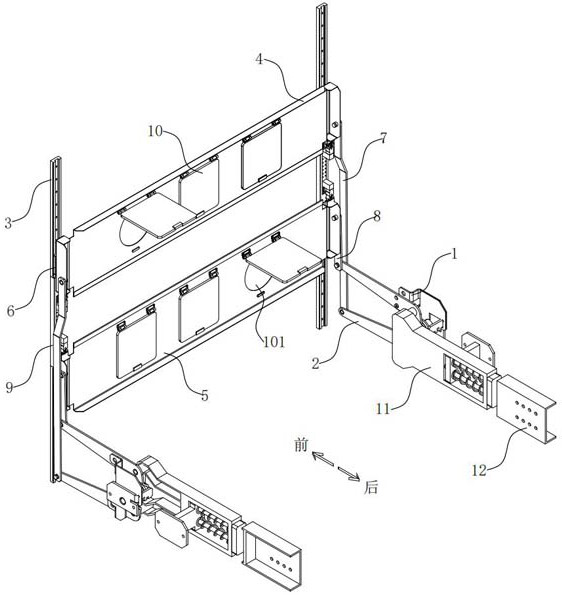

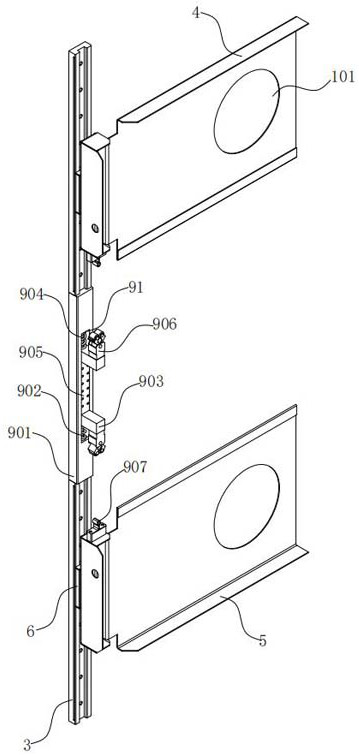

[0033] see Figure 1 to Figure 9 , the present invention provides a technical solution:

[0034]A valve locking mechanism, including a mounting frame 1, a crank mechanism 2, a sliding groove 3, an upper valve 4, a lower valve 5, a sliding block 6, an upper connecting rod 7, a lower connecting rod 8, a buffer fixing mechanism 9, and an inspection door 10 , pushing mechanism 11 and impact frame 12, wherein:

[0035] The sliding groove 3 and the buffer fixing mechanism 9 are installed on the contact box partition 13 of the handcart room of the switch cabinet, the sliding groove 3 is arranged on the upper and lower ends of the buffer fixing mechanism 9, and the upper valve 4 and the lower valve 5, a sliding block 6 is fixed on the side, and the sliding block 6 connected to the upper valve 4 and the lower valve 5 is respectively stuck in the sliding groove 3 at the upper and lower ends of the buffer fixing mechanism 9, and the sliding block 6 can slide up and down in the sliding g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com