Automatic antenna chip welding device for RFID (Radio Frequency Identification Device) production

An automatic welding and chip technology, applied in the field of RFID, can solve problems such as hindering the welding work of devices, reducing the yield of finished products, and reducing welding efficiency, so as to reduce production costs, prevent false welding, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

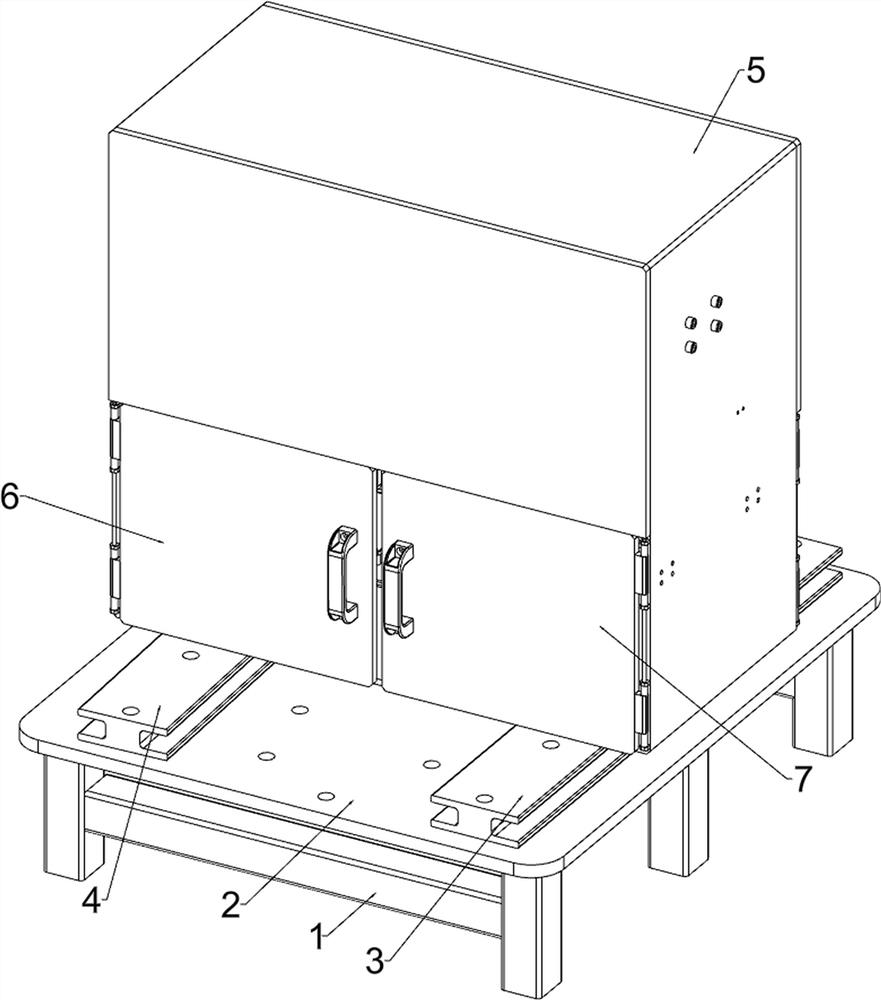

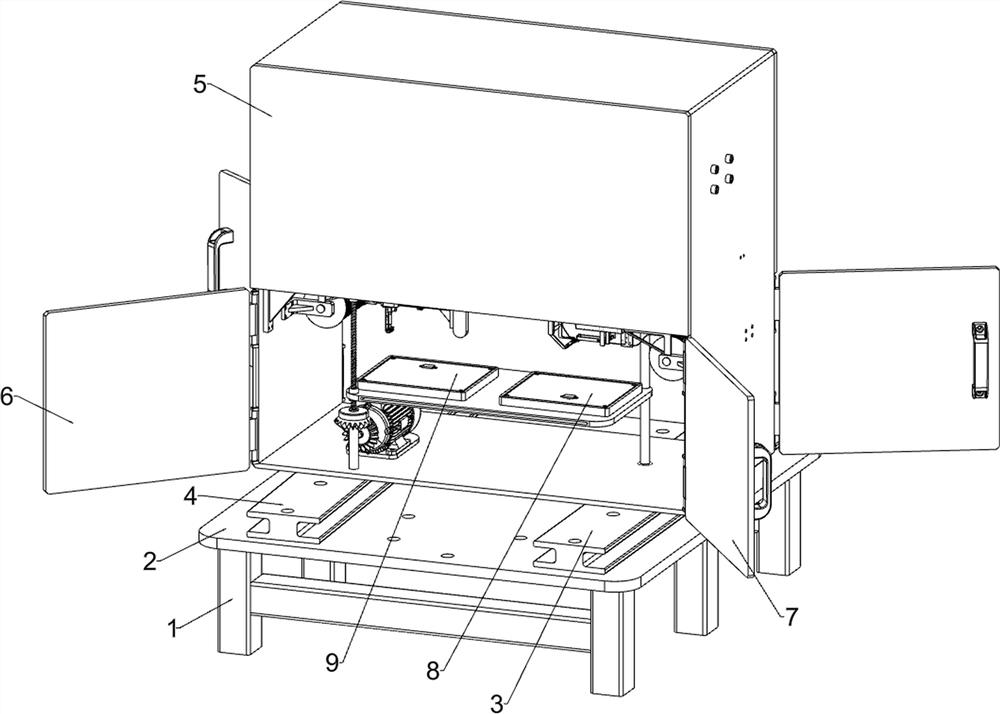

[0038] An automatic welding device for RFID production antenna chips, such as Figure 1-13 As shown, it includes a fixing frame 1, a bottom plate 2, a first bolt fixing plate 3, a second bolt fixing plate 4, a protective frame 5, a first hatch 6, a second hatch 7, a first analog chip 8, a second Analog chip 9, welding assembly, chip conveying assembly, solder conveying assembly and antenna conveying assembly; the upper side of the fixing frame 1 is fixedly connected with the bottom plate 2; The left part is fixedly connected with a second bolt fixing plate 4; the upper side of the first bolt fixing plate 3 and the upper side of the second bolt fixing plate 4 are equipped with a protective frame 5; the lower side of the protective frame 5 is equipped with a first hatch 6; A second hatch 7 is installed below the front side of the frame 5, and the second hatch 7 is positioned at the right side of the first hatch 6; group; the inner upper part of the protective frame 5 is bolt-co...

Embodiment 2

[0047] On the basis of Example 1, such as figure 1 , figure 2 , image 3 , Figure 14 with Figure 15 As shown, it also includes a solder overflow prevention assembly, which is located on the lower side of the solder delivery assembly, and the solder overflow prevention assembly includes a first connecting frame 601, a second connecting frame 602 and a limit frame 603; the fifth driving part 408 The first connecting frame 601 is fixedly connected to the lower side; the second connecting frame 602 is fixedly connected to the lower side of the sixth driving part 409; One connecting frame 601 and the second connecting frame 602 are all provided with one on the lower side of the two fifth driving parts 408 and the sixth driving part 409; A spacer 603 is connected.

[0048] When the 8-first analog chip and the 9-second analog chip rise to the above-mentioned height, one side of the 8-first analog chip and the 9-second analog chip are respectively in contact with the protrudin...

Embodiment 3

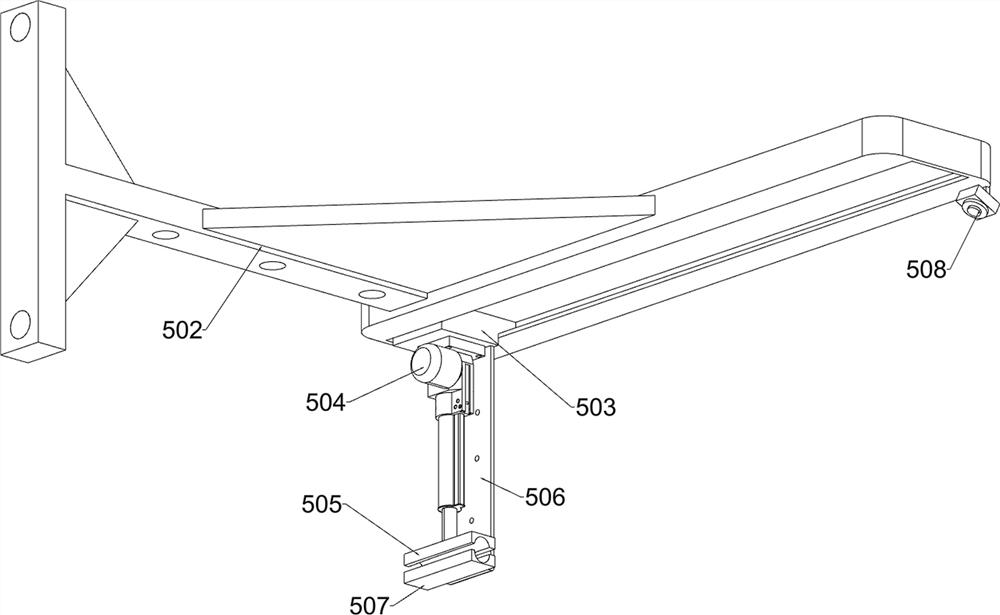

[0050] On the basis of Example 2, such as figure 1 , figure 2 , image 3 , Figure 16 , Figure 17 with Figure 18 As shown, a solder processing assembly is also included, the solder processing assembly is located on the upper side of the welding assembly, and the solder processing assembly includes a seventh connecting plate 701, an eleventh driving component 702, an eighth connecting plate 703, and a fifth L-shaped connecting plate 704 , the first telescopic part 705, the second telescopic part 706, the third telescopic part 707, the ninth connecting plate 708, the push plate 709, the limit protection block 7010 and the push block 7011; The connecting plate 701; the eleventh drive part 702 is fixedly connected to the lower side of the seventh connecting plate 701; the eighth connecting plate 703 is fixedly connected to the lower side of the eleventh driving part 702; the fifth connecting plate 703 is fixedly connected to the lower side L-shaped connecting plate 704; th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap