Follow-up tool magazine mechanism capable of reducing deformation of cross beam

A technology of follow-up and tool magazine, which is applied in the direction of metal processing machinery parts, clamping, support, etc., can solve the problems of beam deformation and affect the machining accuracy of machine tools, and achieve the effect of reducing deformation and beam deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

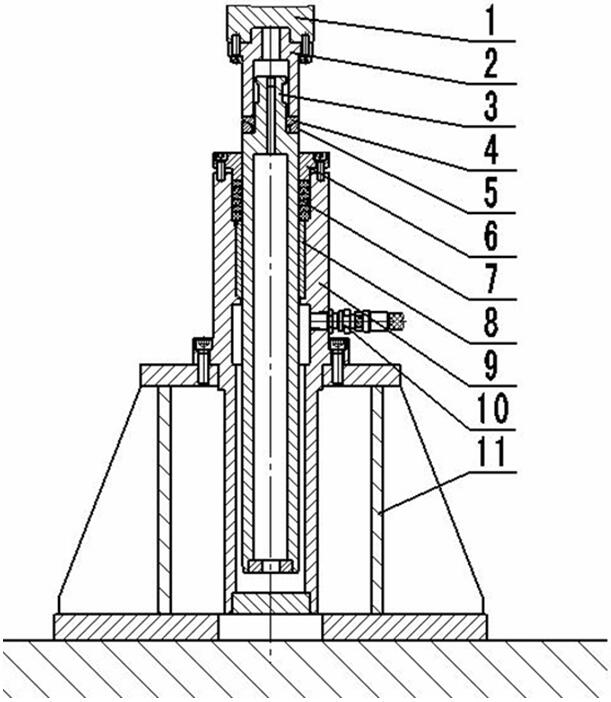

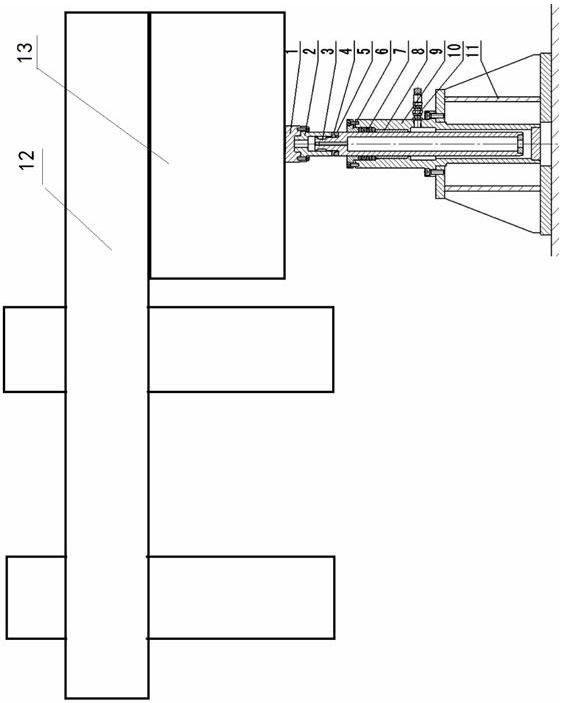

[0012] like Figure 1-2 As shown, a rotary knife library mechanism that reduces the beam deformed, including the follow-up bracket 2, the follower shaft 3, the spherical gasket 4, the cone gasket 5, the flange 6, the combination seal, the support sleeve 8, The fixing bracket 9, the joint 10, and the base 11, the base 11 is located directly below the beam 12, and the base 11 is fixed to the ground by the foot bolt, and the fixing bracket 9 is fixed to the base 11 by the screw. The fixed bracket 9 is opened with an axle cavity, and the flow shaft 3 is inserted from the top, and the fixed bracket 9 and the bracket shaft 3 are provided with a support sleeve 8 for radial supporting the casing 3, support sleeve. Above 8 is provided in a fixed bracket 9 and a combined seal 7 on the follow-up shaft 3, the foil shaft 3 end is sleeve with a flange 6 sealing the fixing bracket 9, the flange 6 is fixed by the screw On the fixing bracket 9, the combined sealing ring 7 is pressed by adjusting th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com