Construction assembly system of polymer composite waterproof chassis

An assembly system and polymer technology, applied in roof insulation materials, roofing, construction, etc., can solve problems such as the installation of molecular composite waterproof chassis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

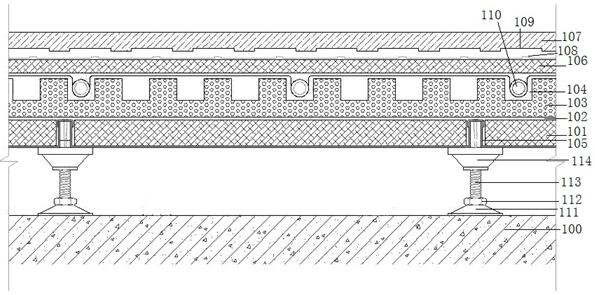

[0016] Such as figure 1 The construction and assembly system of the polymer composite waterproof chassis shown includes the first frame plate with heat insulation layer 101 laid on the base layer 100, and the first waterproof glue coated on the first frame plate with heat insulation layer 101. Adhesive layer 102, and the support frame plate 103 with a sound-insulating layer on the first waterproof adhesive layer 102, and the draw-in groove 104 arranged on one side of the support frame plate 103 with sound-insulation layer, and the limiter set in the draw-in groove 104 Position protrusion 110, and the second band heat-insulating layer frame plate 106 that is connected with position-limiting protrusion 110, and the second waterproof adhesive layer 108 that is all coated on the second band heat-insulating layer frame plate 106, and is arranged on The waterproof chassis 107 on the second waterproof adhesive layer 108 .

Embodiment 2

[0018] Such as figure 1 The construction and assembly system of the polymer composite waterproof chassis shown includes the first frame plate with heat insulation layer 101 laid on the base layer 100, and the first waterproof glue coated on the first frame plate with heat insulation layer 101. Adhesive layer 102, and the support frame plate 103 with a sound-insulating layer on the first waterproof adhesive layer 102, and the draw-in groove 104 arranged on one side of the support frame plate 103 with sound-insulation layer, and the limiter set in the draw-in groove 104 Position protrusion 110, and the second band heat-insulating layer frame plate 106 that is connected with position-limiting protrusion 110, and the second waterproof adhesive layer 108 that is all coated on the second band heat-insulating layer frame plate 106, and is arranged on The waterproof chassis 107 on the second waterproof adhesive layer 108, and the glue material that is arranged on one side of the water...

Embodiment 3

[0020] Such as figure 1 The construction and assembly system of the polymer composite waterproof chassis shown includes the first frame plate with heat insulation layer 101 laid on the base layer 100, and the first waterproof glue coated on the first frame plate with heat insulation layer 101. Adhesive layer 102, and the support frame plate 103 with a sound-insulating layer on the first waterproof adhesive layer 102, and the draw-in groove 104 arranged on one side of the support frame plate 103 with sound-insulation layer, and the limiter set in the draw-in groove 104 Position protrusion 110, and the second band heat-insulating layer frame plate 106 that is connected with position-limiting protrusion 110, and the second waterproof adhesive layer 108 that is all coated on the second band heat-insulating layer frame plate 106, and is arranged on The waterproof chassis 107 on the second waterproof adhesive layer 108, and the glue material that is arranged on one side of the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com