Porcelain granule building material and process for manufacturing the same

A technology of building materials and ceramsite, which is applied in the direction of ceramic products, clay products, applications, etc., and can solve problems such as easy water seepage and strength discount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

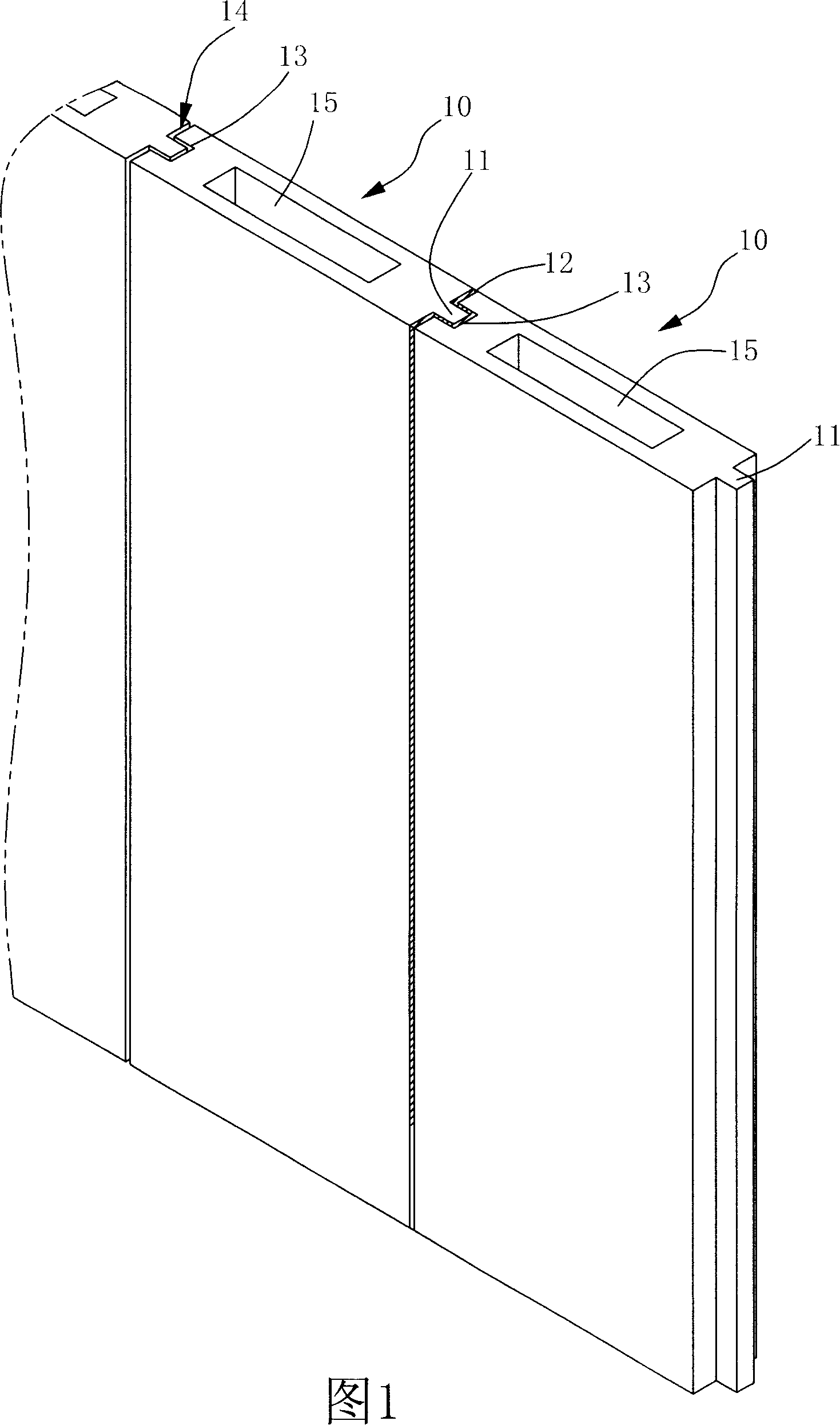

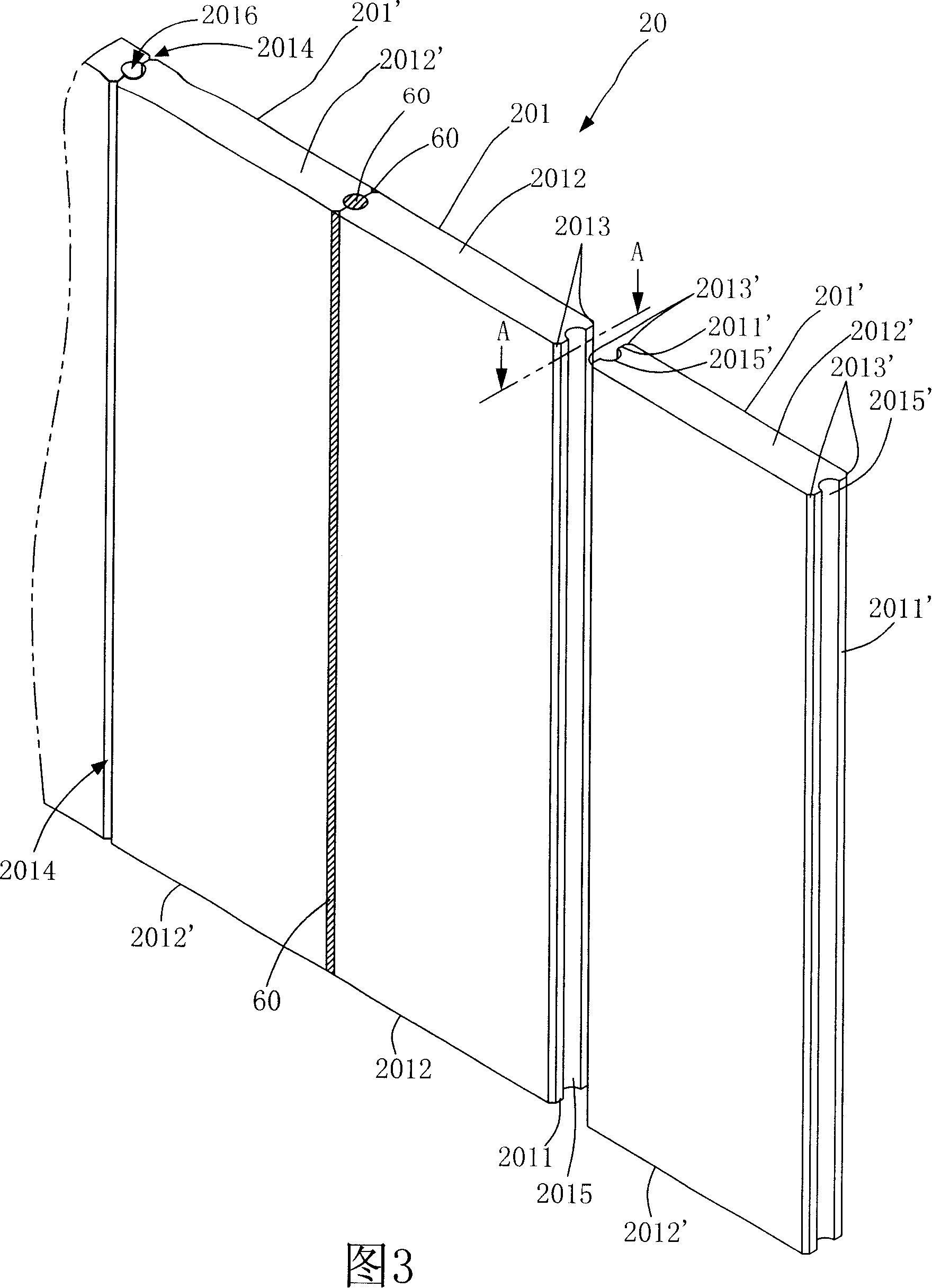

[0026] In order to more clearly describe the ceramsite building material and manufacturing method proposed by the present invention, the following will be described in detail with the accompanying drawings.

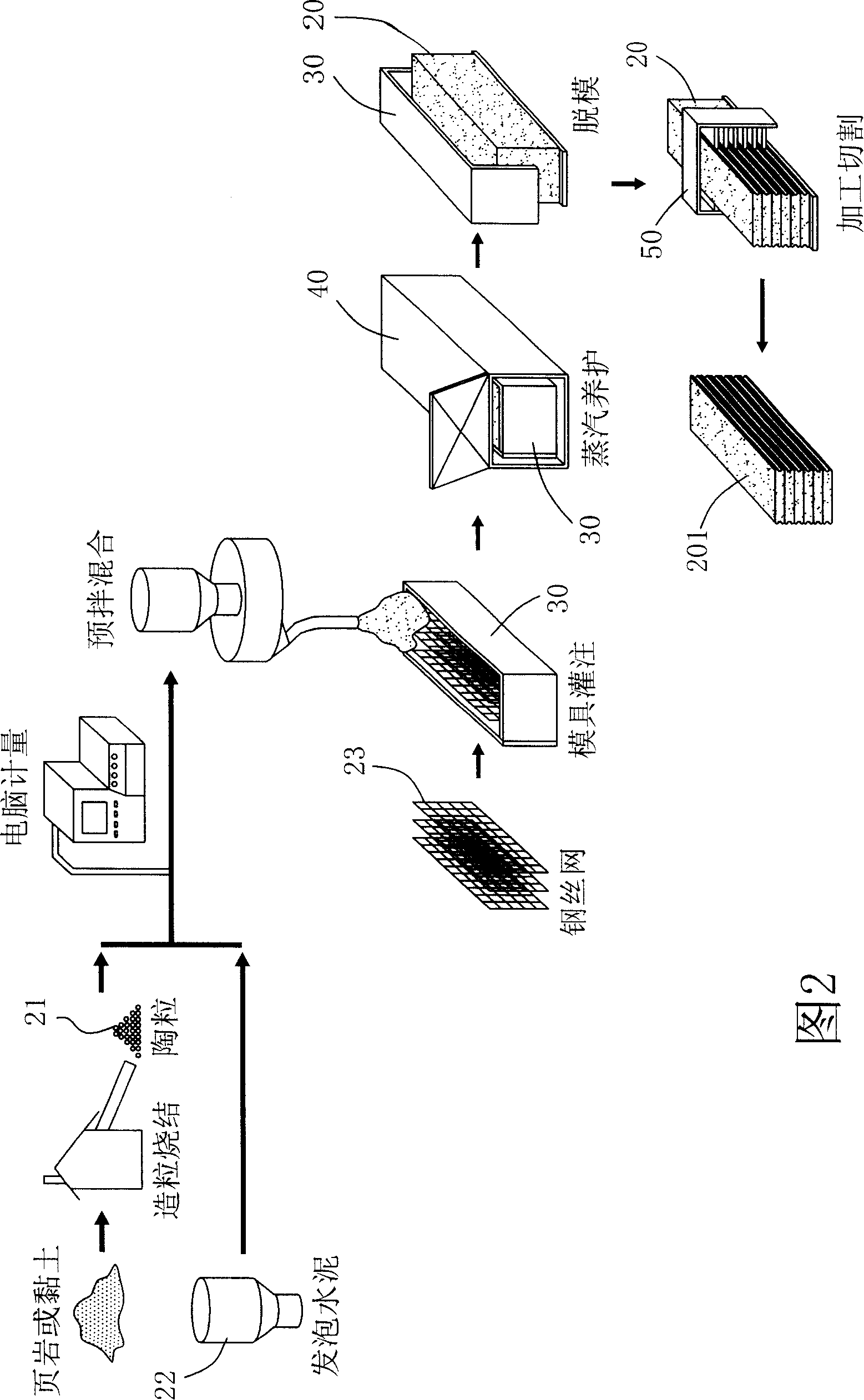

[0027] Please refer to FIG. 2, which is a schematic diagram of the production process of the ceramsite building material of the present invention. Wherein, the ceramsite building material includes: several ceramsite 21 , foam cement 22 , and steel wire mesh 23 . The ceramsite 21 is a ceramic texture and porous artificial ceramic particles. After the ceramic granulation is formed, it is sintered in a high-temperature kiln above 1050°C to form a light granular shape. It can be sintered from shale or clay. It has high hardness and thermal conductivity. It has the characteristics of low coefficient, light weight, high temperature resistance, acid and alkali resistance, etc., and has good effects of fire prevention, heat insulation, heat preservation, sound insulation, moistur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com