High-toughness automobile waterproof sealing strip and preparation method thereof

A technology of waterproof sealing and high toughness, which is applied in the field of high toughness automobile waterproof sealing strip and its preparation, which can solve the problems of poor oil resistance and other problems, and achieve the effect of improving strength, stable performance, and improving oil and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

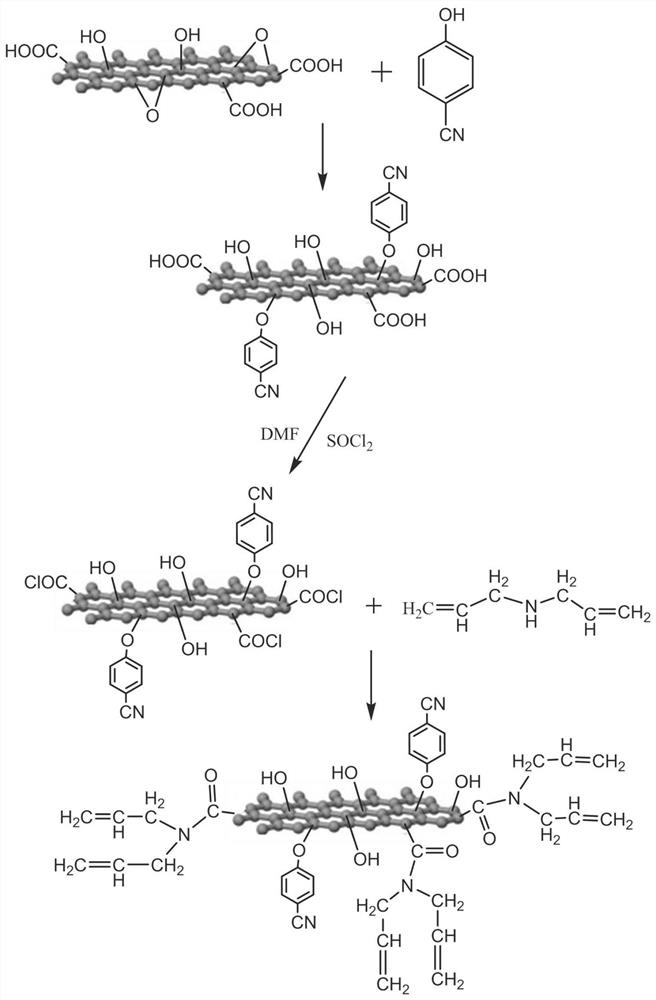

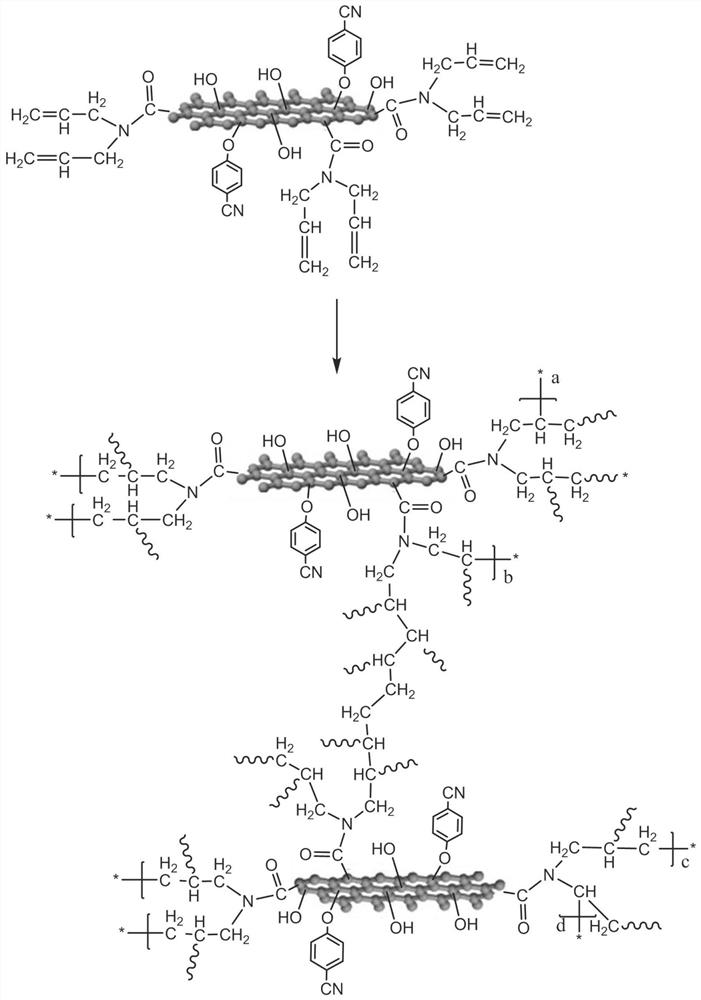

[0029] Cyano - preparation of amides specific unsaturated monomer in the graphene oxide:

[0030] Step 1 Weigh the graphene oxide 1kg 30L water was added, ultrasonic dispersion was warmed to 70 deg.] C 30min, graphene oxide dispersion liquid was poured into the reaction flask, followed by addition of 110g paraben-carbonitrile To the reaction flask was maintained at 70 ℃ for 5h, and then the product was filtered off with suction and washed, to obtain graphene oxide cyano;

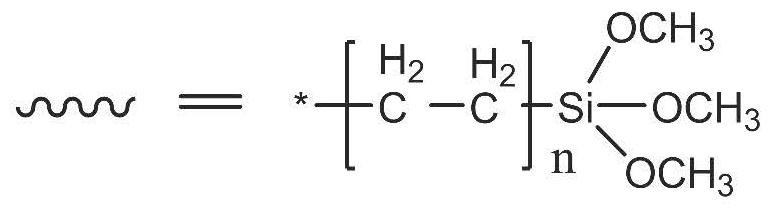

[0031] In step 2, the cyano 1kg graphene oxide prepared in Step 1 and N, N- dimethylformamide was added to the reaction vessel, an ultrasonic dispersion 50min, 360g was then added to the cyano-dichloro ultrasonic graphene oxide dispersion sulfoxide, heated to 80 ℃, the reaction was stirred for 6h, then concentrated in vacuo. the product was obtained after distillation under reduced pressure to remove excess thionyl chloride and the solvent N, N- dimethylformamide, to give cyano - oxychlorination graphene; a cyan...

Embodiment 2

[0034] Specific preparation of unsaturated amide monomers graphene oxide as follows:

[0035] Step 1, the graphene oxide 1kg and N, N- dimethylformamide was added to the reaction vessel, an ultrasonic dispersion 50min, followed by addition of thionyl chloride to 360g cyano ultrasonic graphene oxide dispersion, the temperature was raised to 80 deg.] C the reaction was stirred 6h, then concentrated in vacuo. the product was obtained after distillation under reduced pressure to remove excess thionyl chloride and the solvent N, N- dimethylformamide, to obtain graphene oxide chloride; cyano since graphene oxide sheet containing a large amount of carboxyl end, under certain conditions can replace the reaction to produce the acid chloride with thionyl chloride occurred;

[0036] Step 2, the oxidation of chloride prepared in Step 1 1kg graphene diethyl ether was added, ultrasonic dispersion was heated to 80 deg.] C 30min, then added diallylamine 170g, the reaction temperature was stirred ...

Embodiment 3

[0038] The diallylamine in Example 1, but with allylamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com