Ultra-short radius horizontal well open hole hydraulic sand blasting deep penetration system and penetration method

An ultra-short radius, horizontal well technology, used in wellbore/well components, directional drilling, earth-moving drilling, etc., can solve problems such as low reservoir permeability, achieve good flexibility, and improve oil-increasing effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

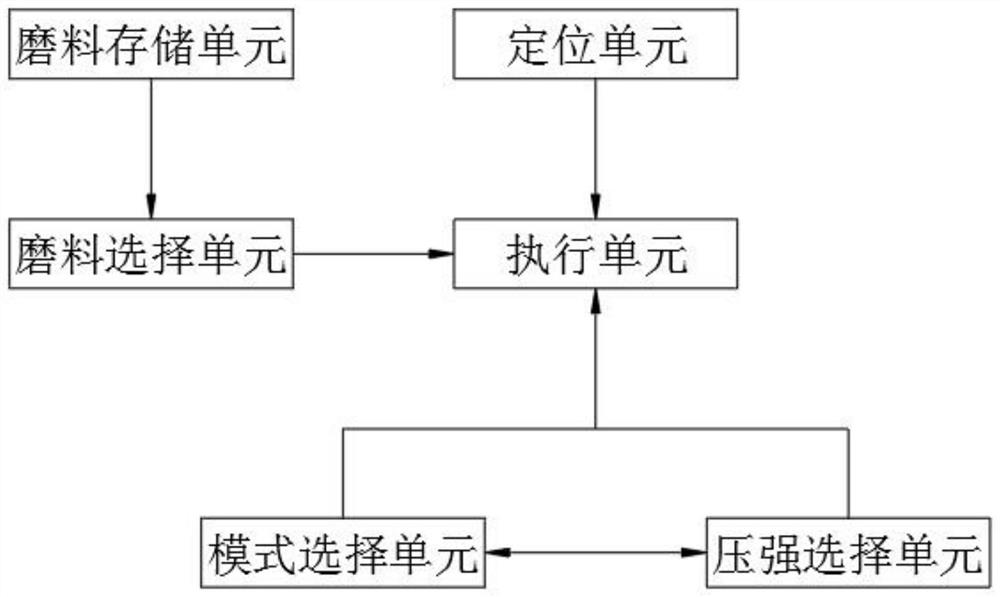

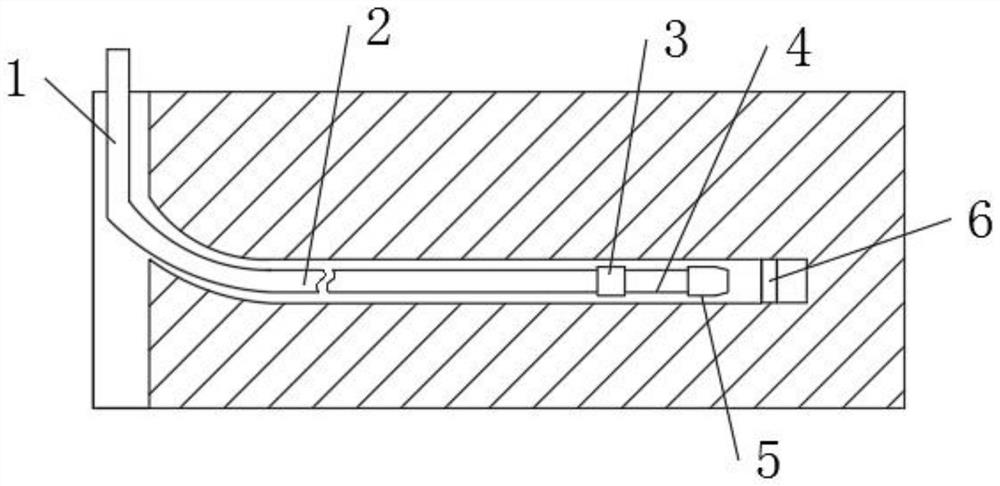

[0040] See Figure 1-2 In the embodiment of the present invention, the ultra-short radius level well bare eye hydraulic sandstick deep penetration system, including abrasive selection units, abrasive storage units, pressure selection units, mode selection units, positioning units, and execution units;

[0041] Among them, the abrasive selection unit is used to detect the thickness of the penetrating layer, before detecting the thickness of the penetration layer, the soil structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com