Endogenous and exogenous functional microorganism composite huff and puff method

A functional microorganism and microbial technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of reducing the efficiency of microbial crude oil and affecting the effect of microbial field tests, so as to improve the effective utilization rate and improve the field efficiency. The effect of the experiment and the effect of improving the population structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] A high water cut oil well F in Shengli Oilfield 1 , crude oil viscosity 1182mPa.s, reservoir temperature 70°C, reservoir pressure 11.30MPa, water cut>88.0%, effective reservoir thickness 10.5m, porosity 0.45, permeability 910×10 -3 μm 2 , the formation water salinity is 3612mg / L, the daily liquid before implementation is 5.2t / d, and the daily oil is 0.5t / d. Implement the steps of the present invention as follows:

[0058] (1) Screening of test wells

[0059] The temperature of the test oil well is 70°C, the viscosity of formation crude oil is 1182mPa.s, the salinity of formation water is 3612mg / L, and the permeability is 910×10 -3 μm 2 , biopolymer-producing microorganism Sphingomonas 1.0×10 exists in the formation water 2 Individuals / ml and biosurfactant microorganism Geobacillus 2.0×10 2 individual / ml, lack of biogas-producing microorganisms. Oil well screening range consistent with the present invention.

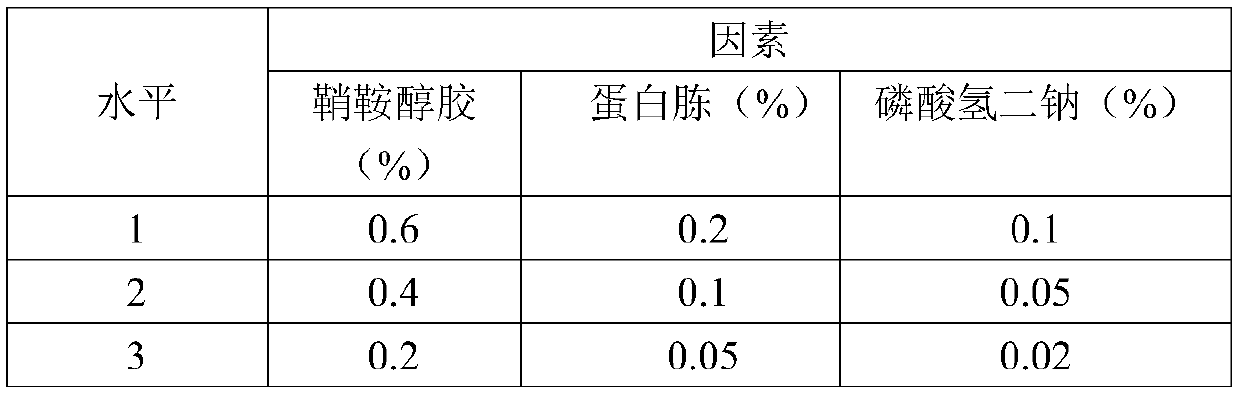

[0060] (2) Screening of endogenous functional microbi...

Embodiment 2

[0099] An oil well H in Shengli Oilfield 2 , the crude oil viscosity is 819mPa.s, the reservoir temperature is 50℃, the reservoir pressure is 11.07MPa, the water content is 97.2%, the effective thickness of the reservoir is 3.8m, the porosity is 0.22, and the permeability is 1230×10 -3 μm 2 , the formation water salinity is 13252mg / L, the daily liquid before implementation is 3.2t / d, and the daily oil is 0.1t / d. Implement the steps of the present invention as follows:

[0100] (1) Screening of oil wells

[0101] Test well H 2 The temperature is 50°C, the viscosity of formation crude oil is 819mPa.s, the salinity of formation water is 13252mg / L, and the permeability is 1230×10 -3 μm 2 , there are biopolymer-producing microorganisms Alcaligenes and aerogenous microorganisms methanogens, and there is a lack of biosurfactant-producing microorganisms. Meet the screening criteria of the oil well of the present invention.

[0102] (2) Screening of endogenous functional microbi...

Embodiment 3

[0141] A low-efficiency oil well G in Shengli Oilfield 1 , the crude oil viscosity is 1663mPa.s, the reservoir temperature is 60℃, the reservoir pressure is 10.07MPa, the water content is 96.8%, the effective thickness of the reservoir is 6.2m, the porosity is 0.30, and the permeability is 680×10 -3 μm 2 , the formation water salinity is 4327mg / L, the daily liquid before implementation is 4.2t / d, and the daily oil is 0.14t / d. Implement the steps of the present invention as follows:

[0142] (1) Screening of test wells

[0143] Test well G 1 The temperature is 60°C, the viscosity of formation crude oil is 1663mPa.s, the salinity of formation water is 4327mg / L, and the permeability is 680×10 -3 μm 2 , biosurfactant-producing microorganism Geobacillus 3.0×10 exists in the formation water 2 / ml and gas-producing microorganism hydrogen-producing bacteria 1.0×10 2 individuals / ml, lacking biopolymer-producing microorganisms. Meet the screening criteria of the oil well of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com