High-voltage-resistant dual-redundancy temperature and humidity sensor

A temperature and humidity sensor, high pressure technology, applied in the field of sensing, can solve the problems of inability to meet sealing requirements, deviation, measurement deviation, etc., and achieve the effect of reducing product failure rate, small measurement error, and high pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

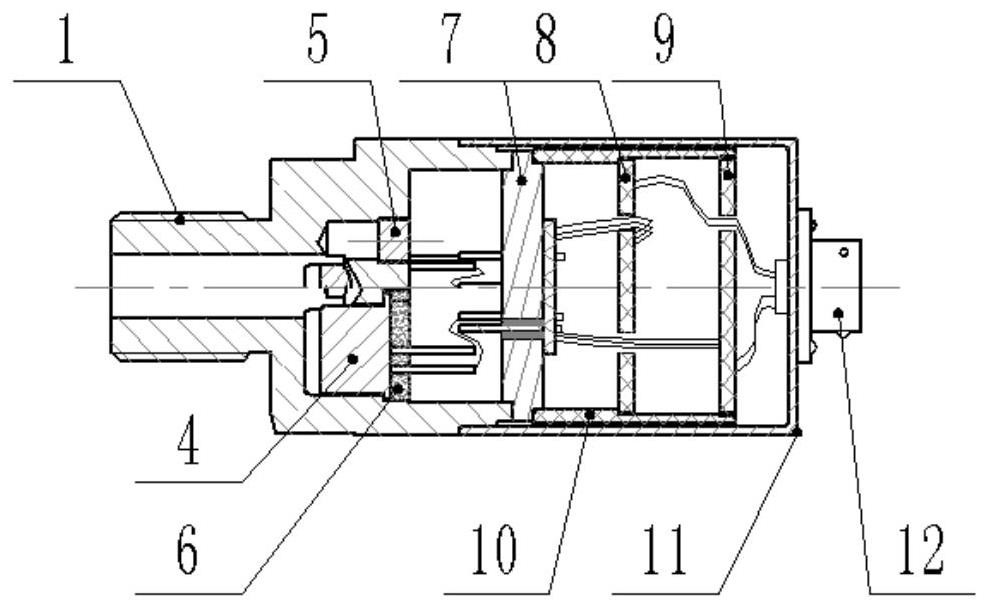

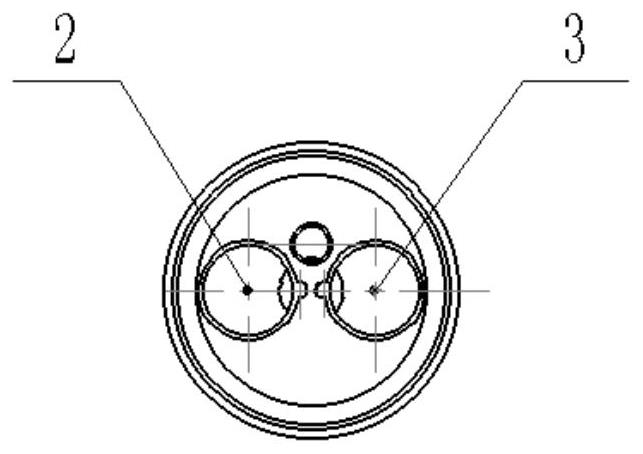

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0009] combine figure 1 and figure 2 , a high-voltage double-redundancy temperature and humidity sensor described in the present invention includes a nozzle 1, a polymer plug 5, a sintered terminal 7, a first circuit board 8, a second circuit board 9, a bracket 10, a housing 11, The electrical connector 12 and the two temperature and humidity sensitive elements 4, the front end of the housing 11 has no end cover, the front end of the housing 11 is fixedly connected to the rear outer wall of the nozzle 1, and an introduction cavity is formed between the two. The nozzle 1 is a revolving body, along its central axis, there are three-stage through holes with increasing diameters from front to back, which are the first-stage holes, the second-stage holes and the third-stage holes in sequence, and the third-stage holes are bottom-oriented. The molecular plug ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com