Method for manufacturing dye-sensitized solar cell

A technology for solar cells and dye sensitization, applied in the field of manufacturing of dye-sensitized solar cells, can solve the problems of increasing thickness of solar cells, rising unit price of production, uneven electrode surface, etc., shortening the manufacturing process, saving production cost, thickness, etc. and surface uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

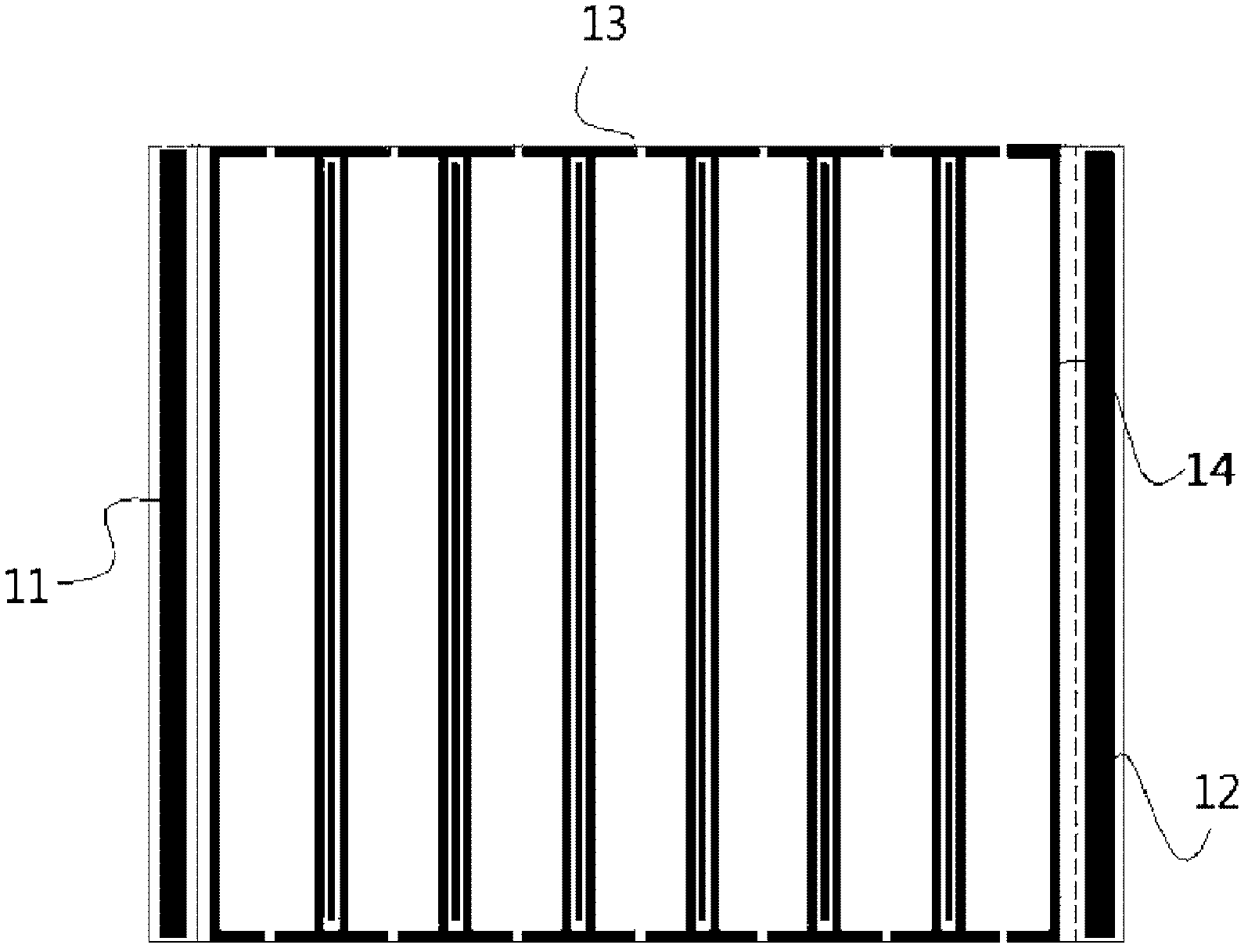

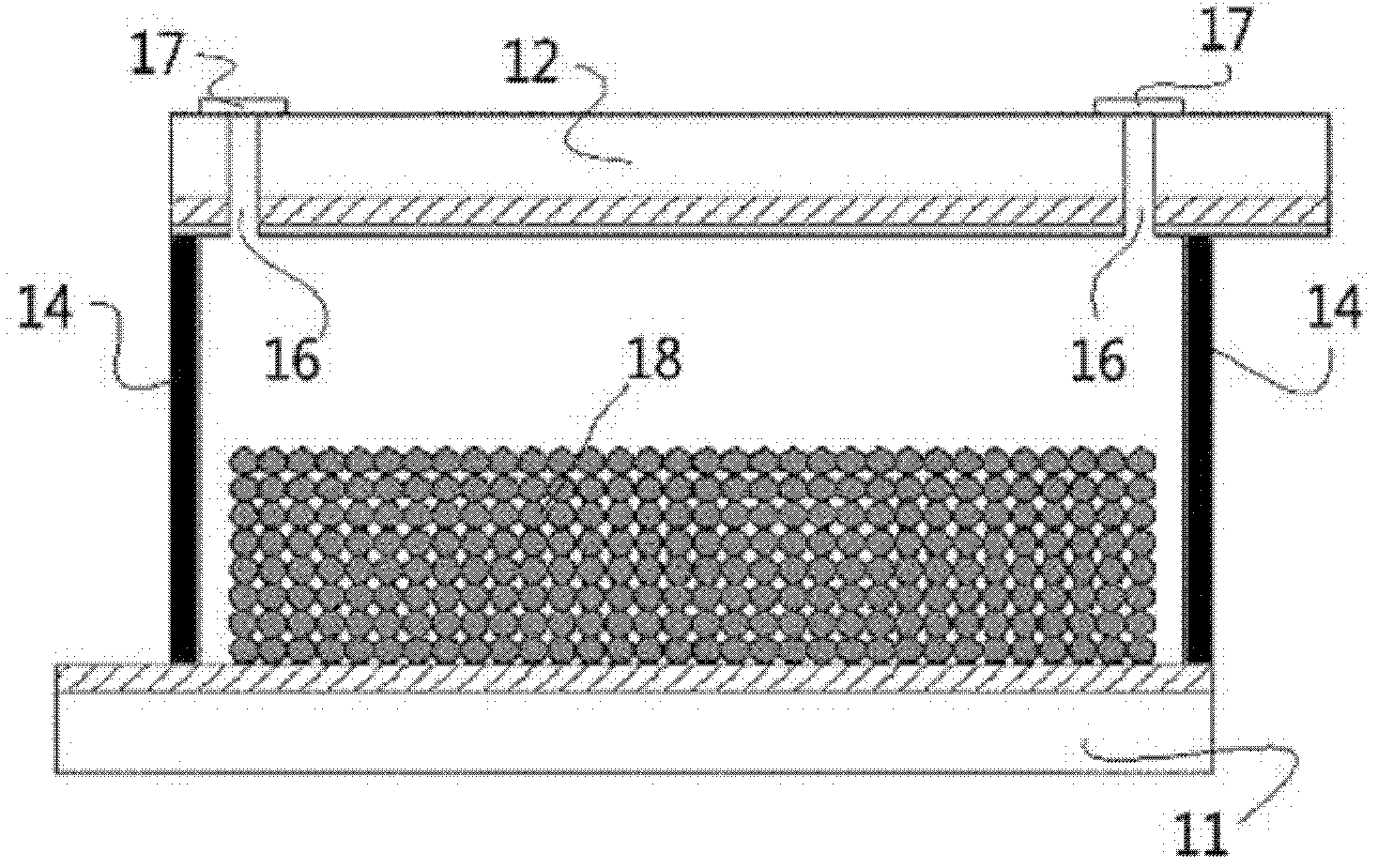

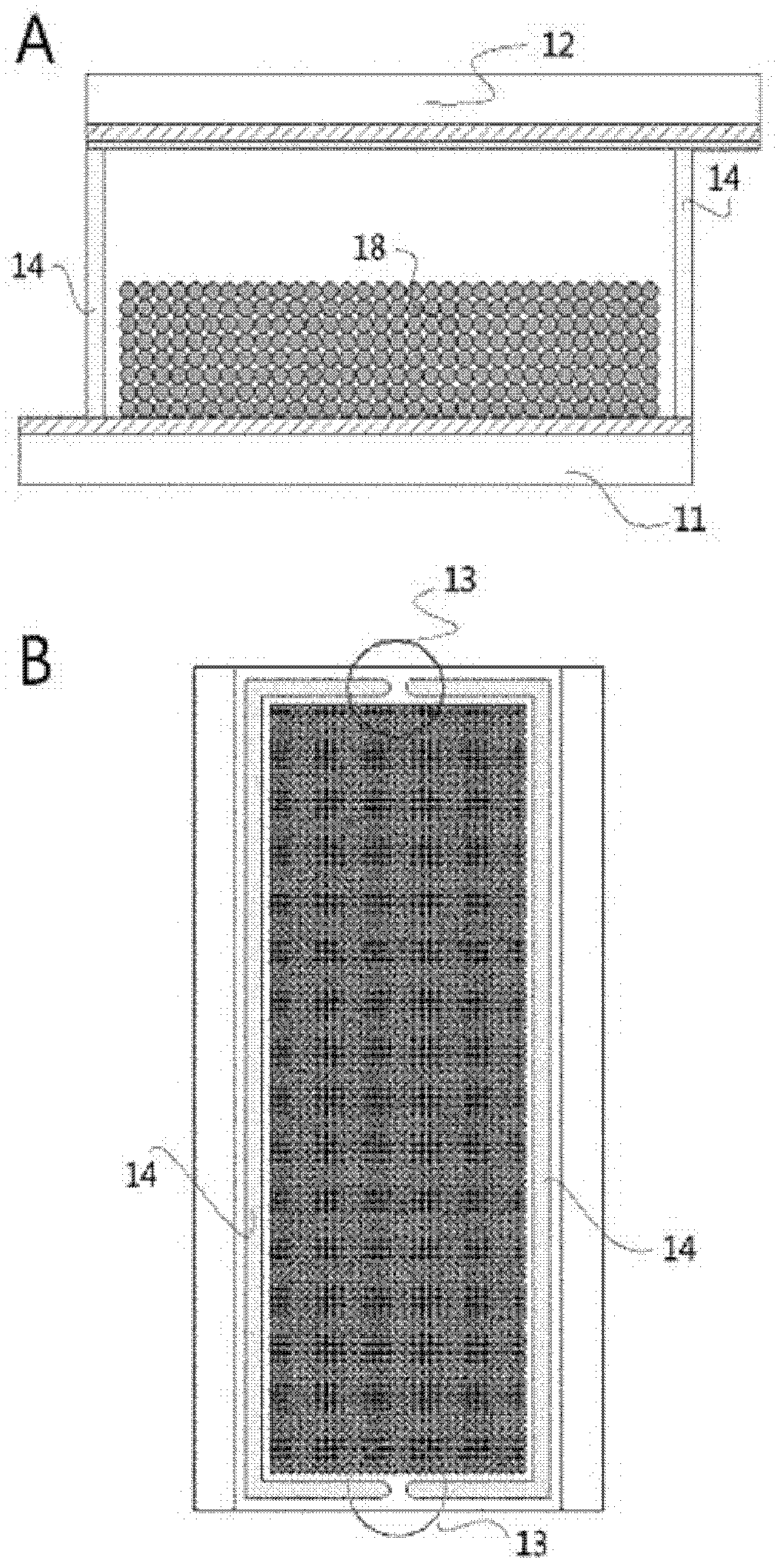

[0030] The present invention will be described in more detail below with reference to the accompanying drawings. However, these drawings and descriptions are merely examples for more easily explaining the content and scope of the technical idea of the present invention, and are not intended to limit or change the technical scope of the present invention. Moreover, those skilled in the art can make various modifications and changes based on these examples and within the scope of the technical idea of the present invention.

[0031] Since the present invention does not relate to the specific constituents of the dye-sensitized solar cell, it does not specifically mention the types of substrates, the types and characteristics of nanoparticle oxides, the types and characteristics of photosensitive dyes, the structure of the counter electrode itself, and the properties and types of electrolytes. Wait.

[0032] In the present invention, the "pre-transparent electrode" refers to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com