Rotary sealing performance testing device and method and processing method

A testing device and air tightness testing technology, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, and by measuring the increase and deceleration rate of the fluid, can solve the problems of high cost, difficult processing, and large inner cavity volume, etc. Achieve the effects of convenient processing and assembly, good test accuracy and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

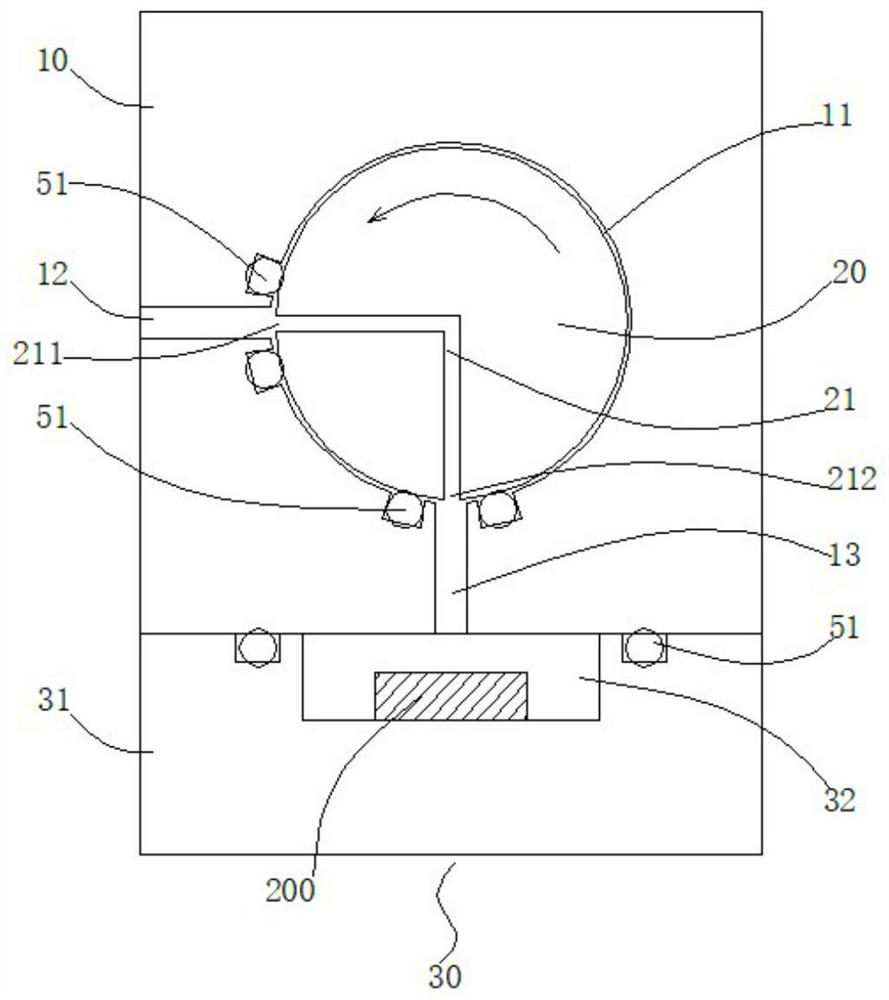

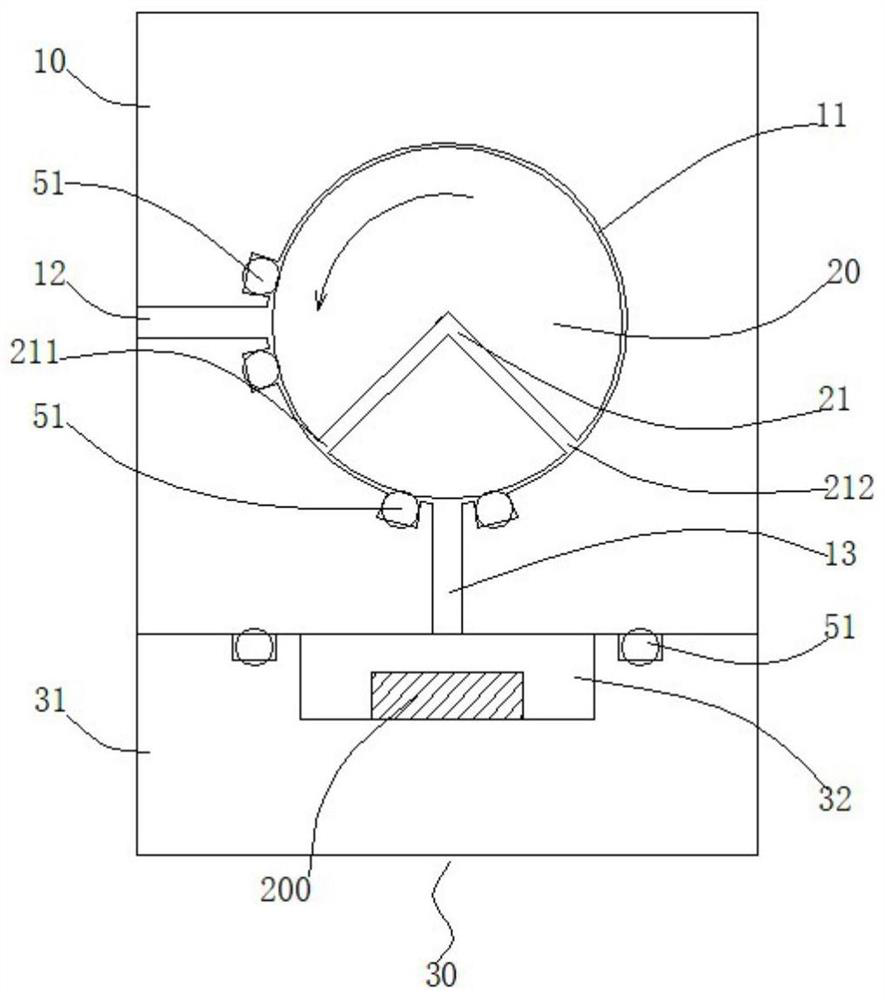

[0178] refer to Figure 1-9 , a rotary sealing test device, including at least one airtightness testing structure, the airtightness testing structure includes a main housing 10, a rotating body 20, and a test fixture 30;

[0179] The inside of the main housing 10 is provided with an accommodating chamber 11, and the main housing 10 is provided with an inlet / exhaust channel 12 and a testing channel 13 respectively connected with the accommodating chamber 11;

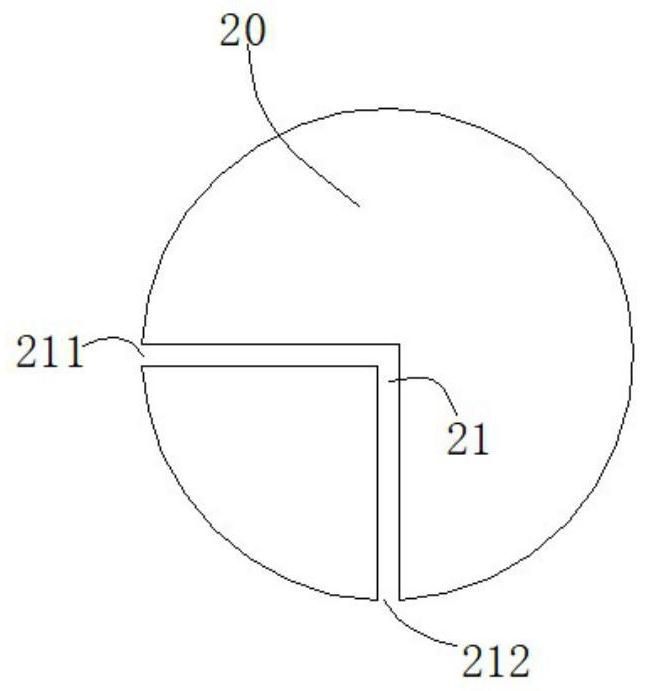

[0180] The rotating body 20 is arranged in the accommodation chamber 11, and can rotate relatively between the rotating body 20 and the main housing 10; an air channel 21 is arranged in the rotating body 20, and the two ends of the air channel 21 have respectively The first connection port 211 and the second connection port 212 for chamber communication;

[0181] The test fixture 30 includes a test fixture body 31, the test fixture body 31 is provided with a test cavity 32, and the test cavity 32 is connected to the test...

Embodiment 2

[0239] Please refer to Figure 10 , the characteristics of this embodiment are: the sealing structure includes a sealing sleeve 52 and a second sealing ring 53 sleeved on the periphery of the rotating body, the side wall of the sealing sleeve is provided with a first through hole and a second through hole, the first through hole It communicates with the first connecting port of the air channel, and the second through hole communicates with the second connecting port of the air channel; a second sealing ring is provided at the opening of the test chamber adjacent to the containing chamber. Specifically, the sealing sleeve may be a rubber sealing sleeve, a hydrogenated nitrile rubber sealing sleeve or a silicon rubber sealing sleeve, and the second sealing ring may be a rubber sealing ring, a hydrogenated nitrile rubber sealing ring or a silicon rubber sealing ring.

[0240] A processing method for a rotary sealing test device, comprising the following steps:

[0241] The main ...

Embodiment 3

[0247] Please refer to Figure 11-13 , the characteristics of this embodiment are:

[0248] It also includes a pressure dividing structure 40, and the main housing is also provided with a pressure dividing channel 14 that communicates with the containing chamber; the pressure dividing structure 40 includes a pressure dividing structure body 41, and a pressure dividing structure body 41 is provided with a pressure dividing chamber 42 , the pressure dividing cavity 42 is connected to the pressure dividing channel 14;

[0249] During the counterclockwise or clockwise rotation of the rotating body relative to the main casing, the airtightness test structure must also meet the following conditions at the same time:

[0250] Condition 3: The first connection port of the gas channel is connected to the test channel, and the connection between them is sealed by a sealing structure; the second connection port of the gas channel is connected to the pressure divider channel, and the conne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap