Linear follow-up bottle mouth crack detection system

A crack detection, linear technology, applied in the direction of measuring devices, optical testing flaws/defects, material analysis through optical means, etc., can solve the problems of high labor costs, fixed detection models, low efficiency, etc., to save labor and labor cost, optimize overall product quality, and improve detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

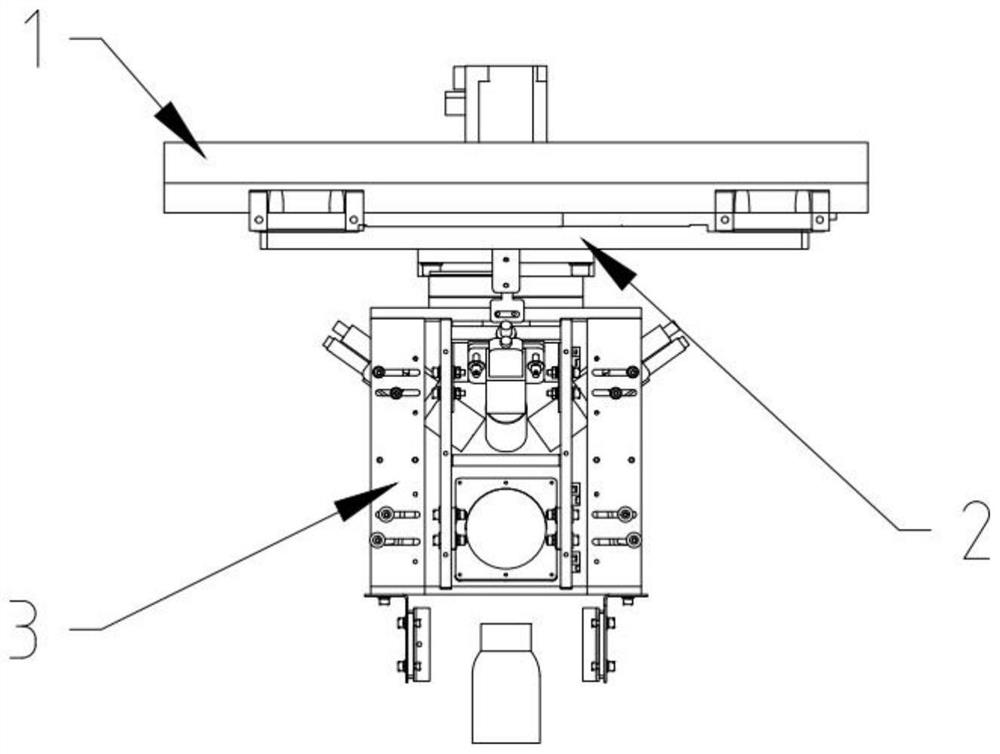

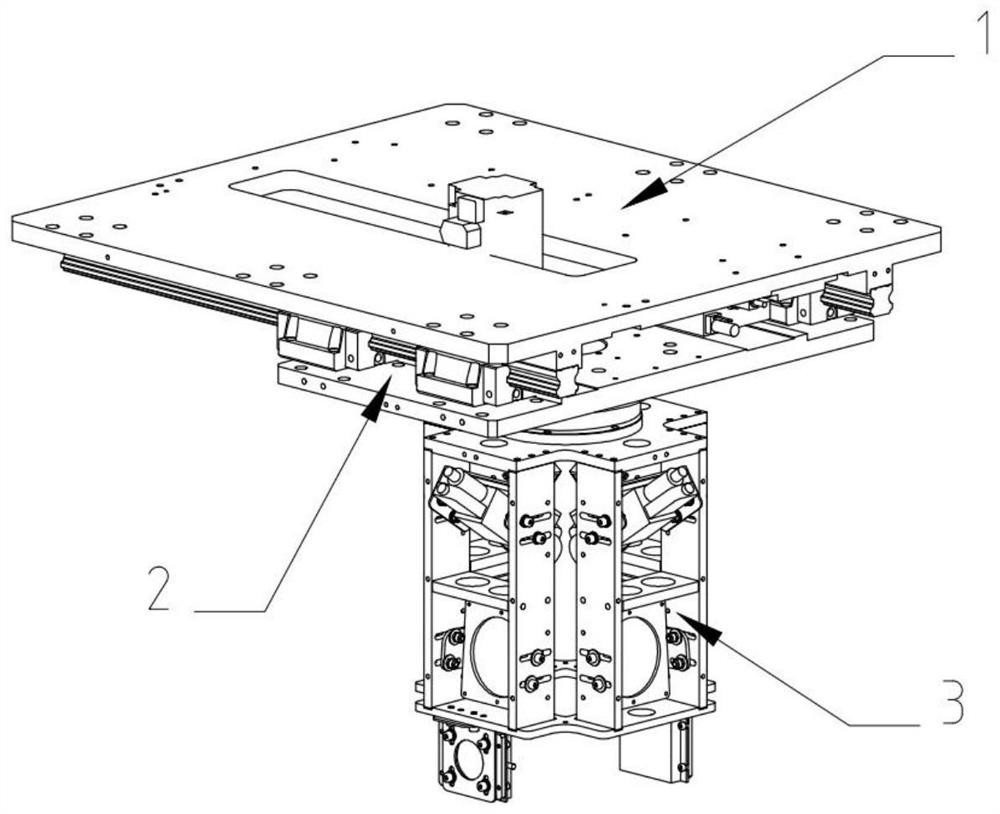

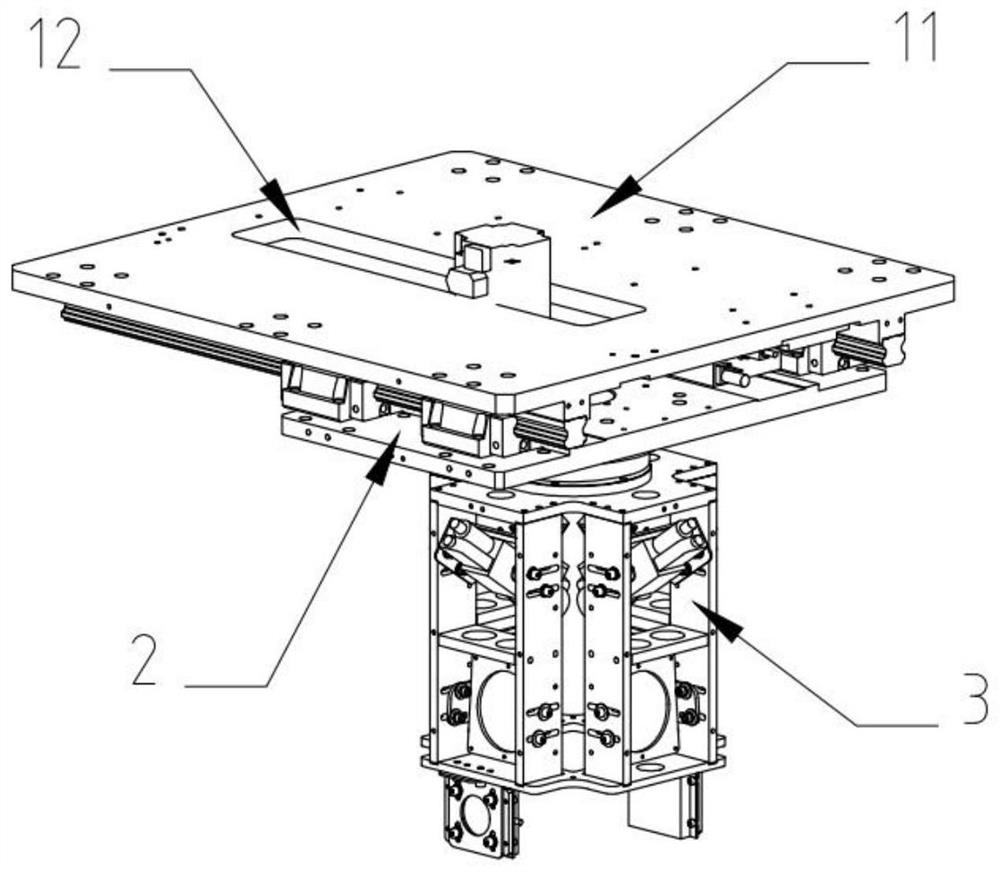

[0040] This embodiment provides a linear follow-up bottle mouth crack detection system, which is used for the quality inspection of glass bottle mouths on the production line, see figure 1 , figure 2 , including a control module, a fixed module 1, a reciprocating follow-up module 2 and a rotating module 3, the control module includes a photoelectric sensor, a PLC control unit and a control panel (not shown), the photoelectric sensor is installed on the glass bottle production line, The operation of the detection system is controlled by detecting the information of the glass bottles on the production line. The fixed module 1 is fixedly installed above the production line, and the glass bottles moving with the production line are arranged above the production line, and the glass bottles themselves do not rotate. The fixed module 1 is located above the moving track of the glass bottle, and a reciprocating follow-up module 2 is slidably connected below it. The reciprocating follo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com