Pouring type conductive concrete heat conduction effect monitoring device

A conductive concrete and effect monitoring technology, which is applied in the field of conductive concrete, can solve problems such as different temperature environment simulations, and achieve the effect of sufficient data and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

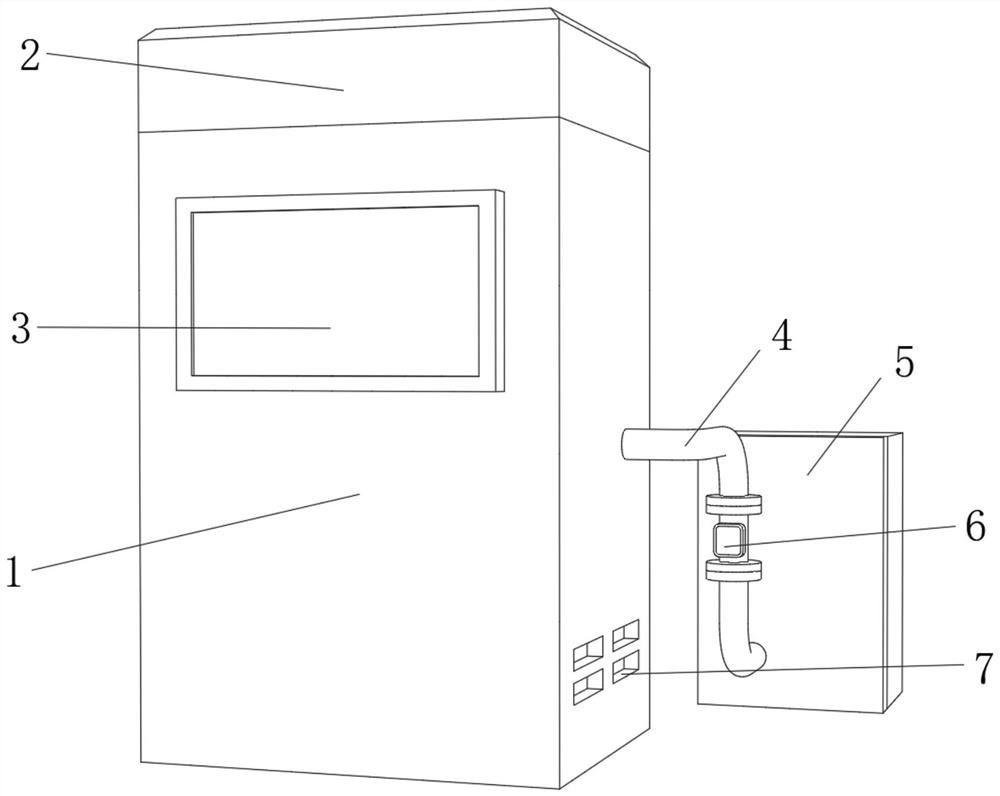

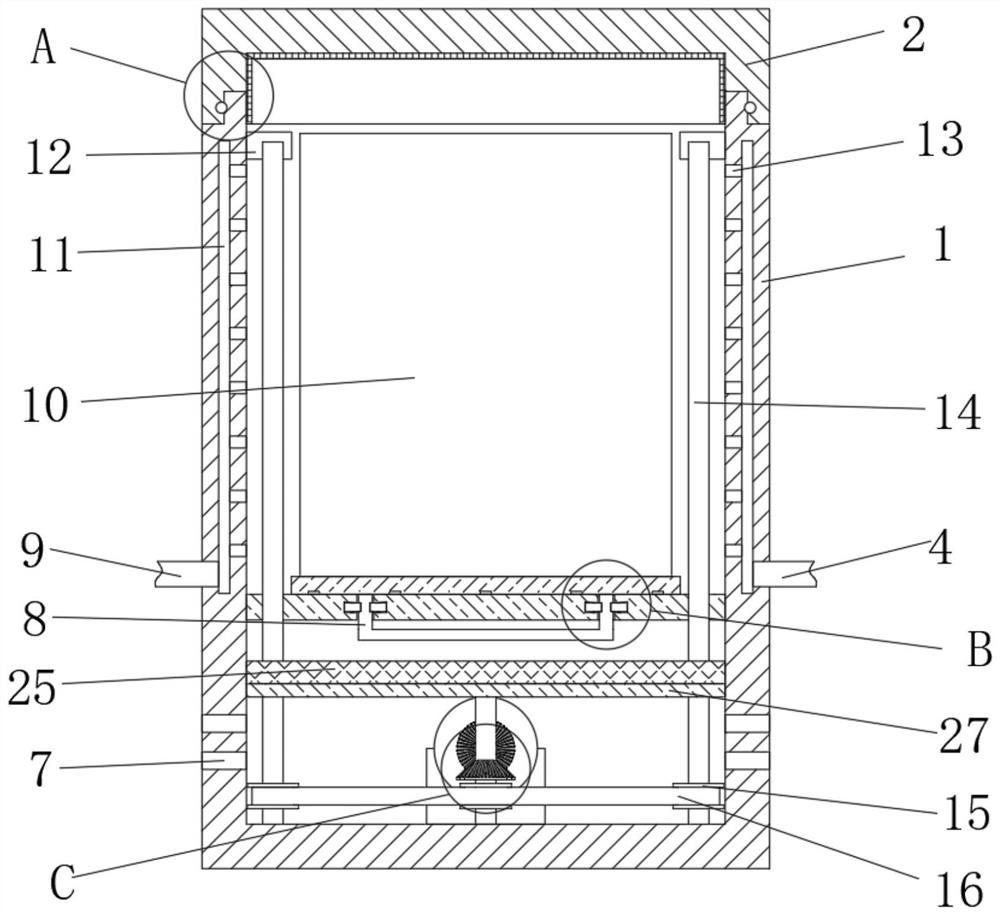

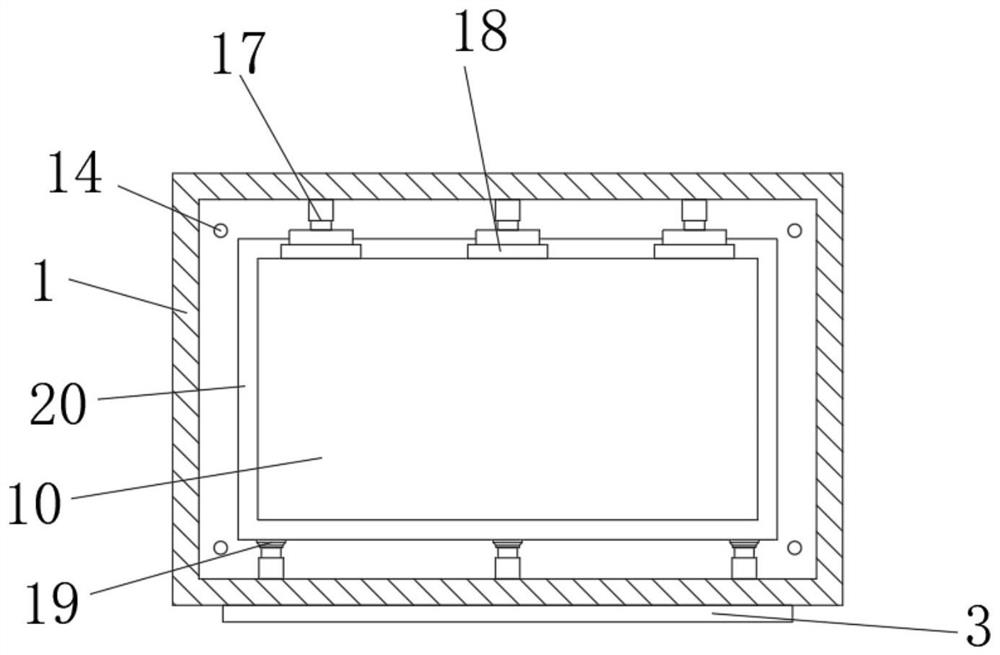

[0030] Such as Figure 1-7 As shown, the embodiment of the present invention provides a pouring conductive concrete heat conduction effect monitoring device, which includes a device main body 1, a cavity 11 is provided inside the upper side wall of the device main body 1, and evenly distributed through holes 13 are provided inside the cavity 11. The through holes 13 all run through the inner side of the upper side wall of the device main body 1, and the bottom of the left side of the cavity 11 is provided with a second air intake pipe 9, and the second air intake pipe 9 is connected to the air compressor unit, so that cold air can be introduced into the Inside the cavity 11, the bottom of the right side of the cavity 11 is provided with a first air intake pipe 4, through the first air intake pipe 4 on the right side of the device main body 1, the hot air generated by the hot air blower 5 can be introduced into the cavity 11, through the cavity The through hole 13 on the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com