Disconnecting link fastening device

A technology of fastening device and knife switch, which is applied in the direction of contacts, electrical components, electric switches, etc., can solve problems such as power grid disconnection, loose contact between static contacts and moving contacts, and influence of users' power consumption, so as to ensure stability , The effect of preventing contact loosening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

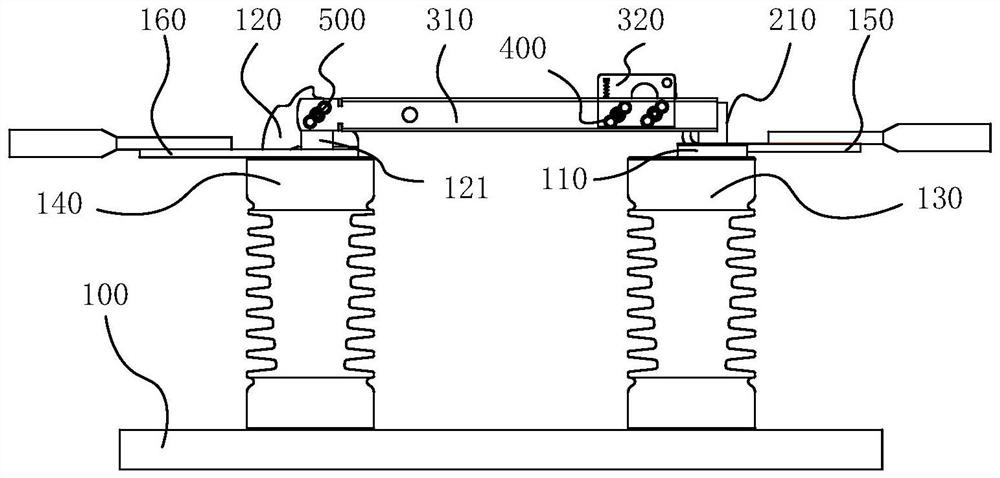

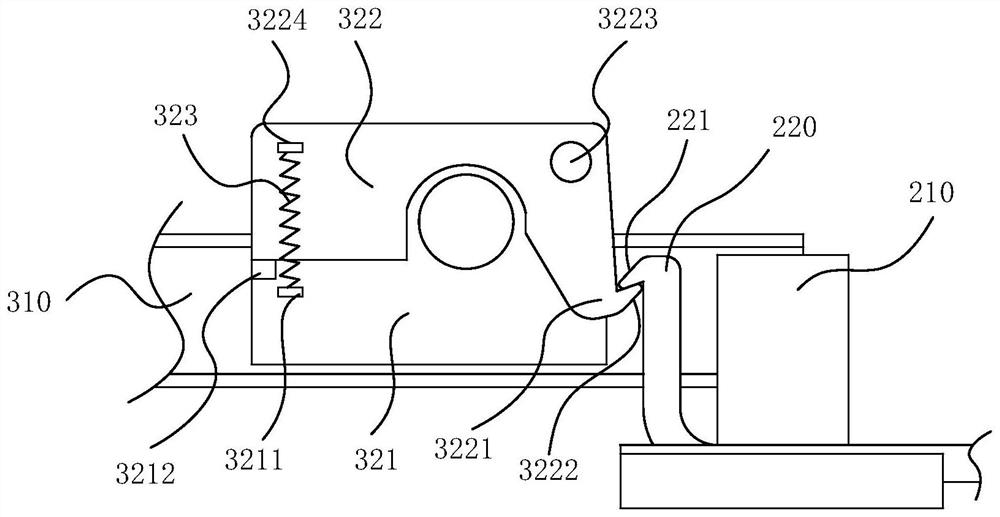

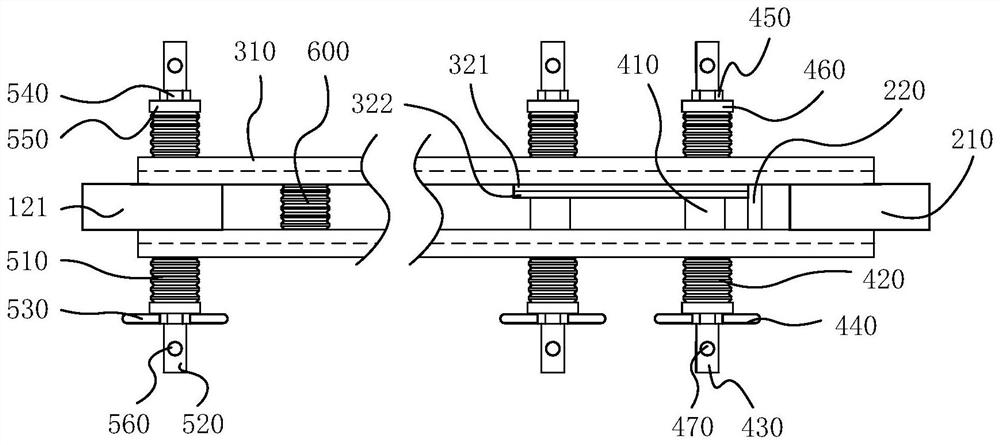

[0053] refer to figure 1As shown, this embodiment provides a knife gate fastening device, including a knife gate base 100, a static contact, a moving contact and a first clamping mechanism 400, and the knife gate base 100 is provided with a fixed seat 110 and a hinged seat 120, the static contact includes a static contact piece 210 and a first buckle mechanism, the static contact piece 210 and the first buckle mechanism are both arranged on the fixed seat 110, the moving contact includes a moving contact piece 310, and the moving contact piece 310 is provided with Two and symmetrically arranged, the first end of the movable contact piece 310 is hinged with the hinge seat 120, and the second end of the movable contact piece 310 is provided with a second buckle mechanism 320 that can be engaged with the first buckle mechanism. When the mechanism is engaged with the second buckle mechanism 320, the two side surfaces of the static contact piece 210 respectively abut against the in...

Embodiment 2

[0072] The first clamping mechanism 400 in the knife switch fastening device provided in this embodiment is different from Embodiment 1. In this embodiment, refer to Figure 6 As shown, the first fastening rod 430 is integrally formed with the first fastening member 440, and the first through hole of the movable contact piece 310 away from the first fastening member 440 is provided with an external thread connected to the second end of the first fastening rod 430. Internal thread for mating connections. Specifically, the second end of the first fastening rod 430 passes through the first elastic member 420, the movable contact piece 310 close to the first fastening part 440, the limit sleeve 410, the fixing plate 321 and the 440 of the moving contact piece 310 and is screwed to the moving contact piece 310 away from the first fastener 440 .

[0073] Further, the second end of the first fastening rod 430 is provided with a first pin hole, and a limit pin is inserted into the fi...

Embodiment 3

[0076] The first clamping mechanism 400 in the knife switch fastening device provided in this embodiment is different from Embodiment 1 and Embodiment 2. In this embodiment, refer to Figure 7 As shown, the first fastening rod 430 can be a bolt, and the threaded end of the bolt is sequentially passed through the first elastic member 420 on one side, the movable contact piece 310 on one side, the fixed plate 321, the limit sleeve 410, and the The moving contact piece 310 and the first elastic member 420 on the other side are screwed to the first fastening member 440 .

[0077] Further, the threaded end of the bolt is provided with a first pin hole, and a limit pin is inserted into the first pin hole to prevent the first fastener 440 from detaching from the first fastening rod 430 .

[0078] Other structures of the knife gate fastening device provided in this embodiment are the same as those in Embodiment 1, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com