Thermal transfer film element

A thermal transfer film and component technology, which can be used in decorative arts, coatings, primers, etc., and can solve problems such as the development of thermal transfer film components that have not yet been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

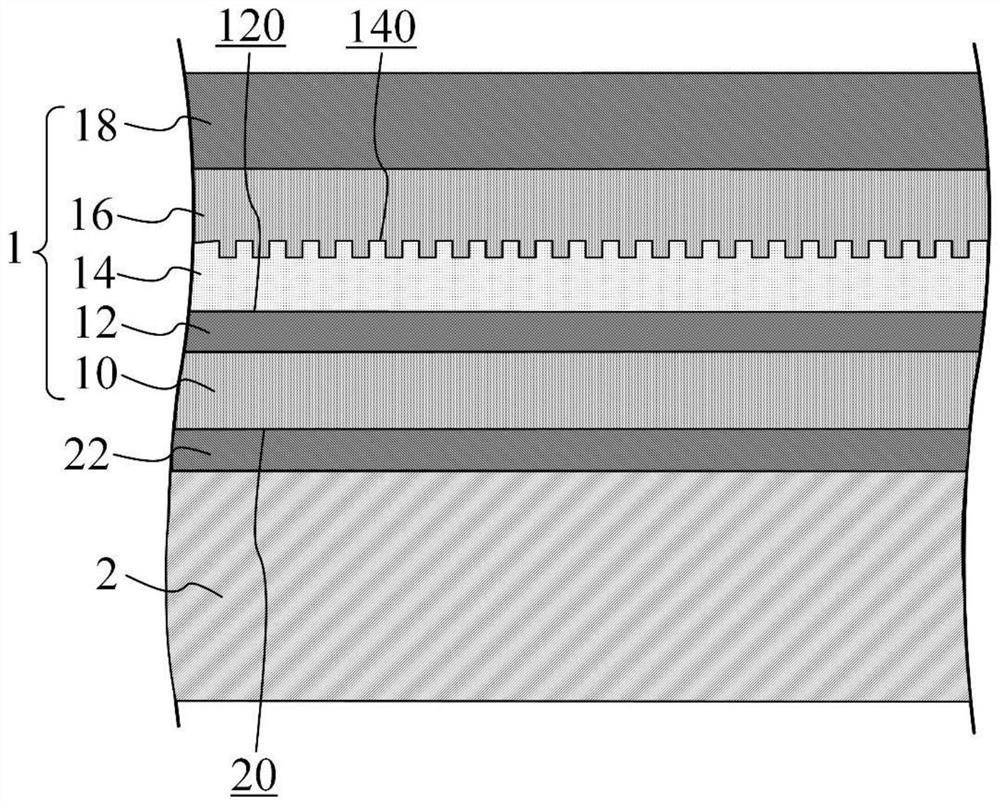

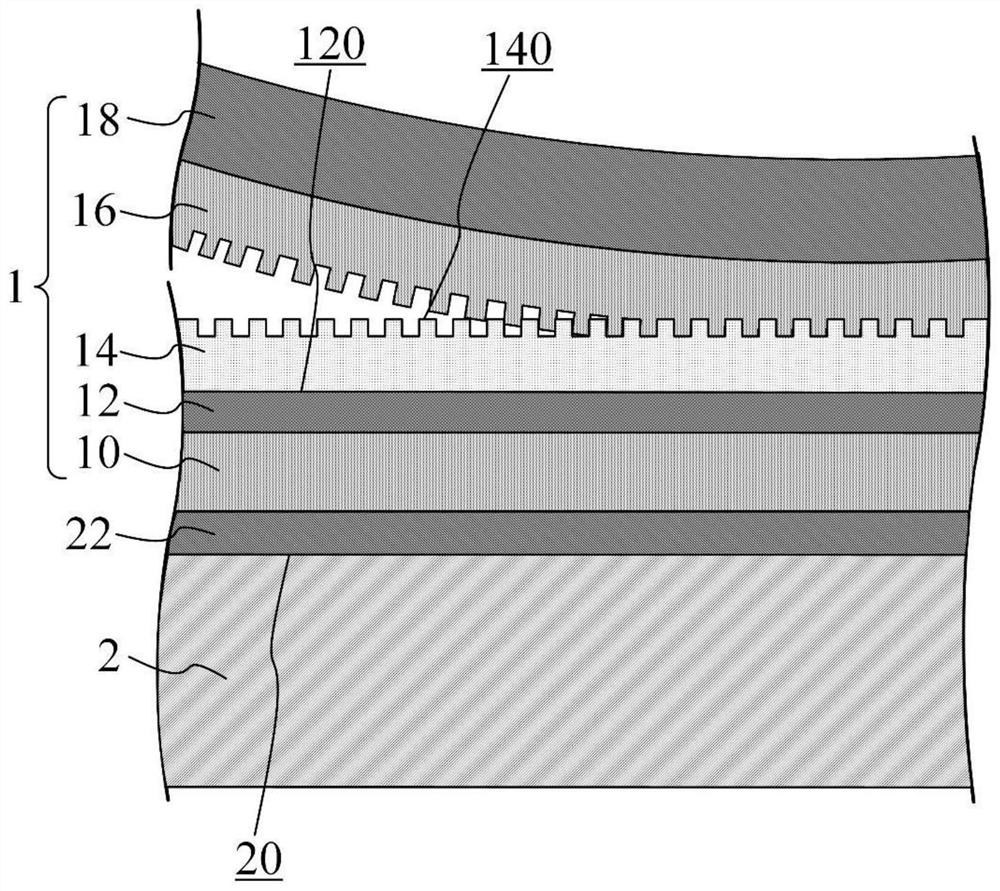

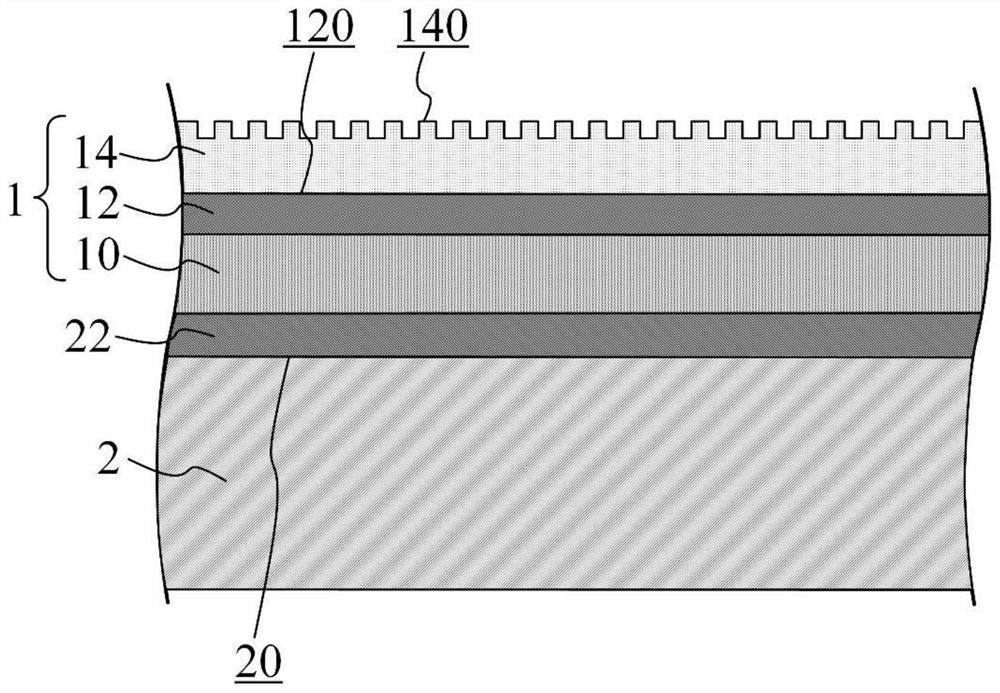

[0074] see figure 1 , figure 2 and image 3 . figure 1 The thermal transfer film element 1 and the attached workpiece 2 according to the first preferred embodiment of the present invention are schematically shown in a partial cross-sectional view. figure 2 The partial cross-sectional view schematically shows the process of removing some elements of the thermal transfer film element 1 according to the first preferred embodiment of the present invention from the workpiece 2 to which it is attached. image 3 A part of the heat transfer film element 1 according to the first preferred embodiment of the present invention is schematically shown in a partial cross-sectional view, in which some elements are transferred to the workpiece 2 to which it is attached and the structure is cured. The workpiece 2 can be a building material, but it is not limited thereto. The building materials may be metal plates such as steel plates and aluminum plates for building exterior walls, profil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com